Are you gearing up for an interview for a Industrial Technologist position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Industrial Technologist and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

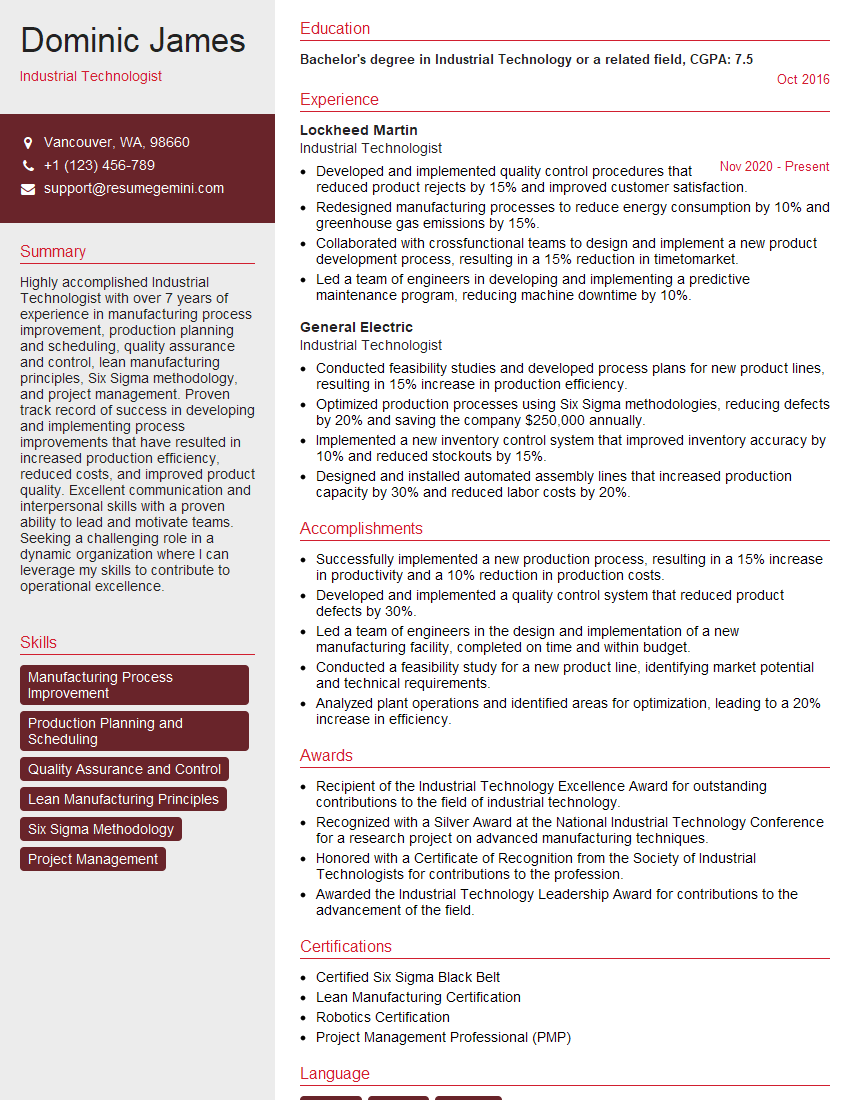

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Technologist

1. What are the key responsibilities of an Industrial Technologist?

As an Industrial Technologist, my primary responsibilities include:

- Collaborating with engineers and other technical professionals to design, develop, and improve industrial processes and systems

- Conducting research and analysis to identify and solve technical problems, optimize operations, and improve efficiency

2. Describe your experience in using statistical techniques for data analysis and process improvement.

Knowledge of Statistical Techniques

- Proficient in applying statistical methods, including hypothesis testing, regression analysis, and time series analysis

- Experienced in using statistical software packages such as SPSS, SAS, or R

Process Improvement

- Utilized statistical techniques to identify inefficiencies and bottlenecks in industrial processes

- Developed and implemented data-driven solutions to improve productivity, reduce waste, and enhance overall performance

3. How do you stay updated with the latest advancements in industrial technology and best practices?

To stay current with the latest advancements and best practices in industrial technology, I actively engage in various professional development activities:

- Attend industry conferences, workshops, and webinars

- Subscribe to technical journals and newsletters

- Participate in online forums and discussion groups

- Conduct self-directed research and explore emerging technologies

4. Explain the role of automation and robotics in modern industrial settings.

Automation and robotics play a significant role in modern industrial settings by:

- Improving efficiency and productivity by automating repetitive tasks

- Enhancing accuracy and precision in manufacturing and assembly processes

- Reducing labor costs and minimizing human error

- Enabling remote monitoring and control of industrial processes

- Facilitating the development of new products and services

5. Describe a project where you successfully applied your knowledge of industrial safety and risk management.

In a previous role, I played a key role in implementing safety improvements at a manufacturing facility:

- Conducted a thorough hazard assessment to identify potential risks

- Developed and implemented safety protocols and procedures

- Trained employees on safety measures and emergency response plans

- Regularly monitored and evaluated safety performance

- Successfully reduced workplace accidents and incidents

6. How do you prioritize and manage multiple projects simultaneously?

To effectively prioritize and manage multiple projects simultaneously, I utilize the following strategies:

- Create a prioritized task list based on project deadlines and importance

- Break down large projects into smaller, manageable tasks

- Delegate tasks to team members when appropriate

- Use project management tools to track progress and identify potential bottlenecks

- Regularly communicate with stakeholders to keep them informed and address any issues

7. What are the key challenges you have faced in your role as an Industrial Technologist, and how did you overcome them?

One of the key challenges I have faced is working with outdated or legacy systems:

- Conducted a thorough assessment of the system to identify areas for improvement

- Explored alternative solutions and technologies

- Collaborated with vendors and engineers to develop a modernization plan

- Successfully upgraded the system, resulting in improved efficiency and reduced maintenance costs

8. Describe your experience in working with cross-functional teams.

Throughout my career, I have consistently worked in cross-functional teams, including engineers, operators, and business analysts:

- Effectively communicated technical concepts to non-technical team members

- Translated business requirements into technical solutions

- Facilitated collaboration and knowledge sharing among team members

- Successfully delivered projects on time and within budget

9. What is your approach to continuous improvement in an industrial setting?

I believe that continuous improvement is essential for maintaining efficiency and competitiveness in an industrial setting:

- Regularly review and analyze process data

- Identify areas for improvement and develop solutions

- Collaborate with stakeholders to implement improvements

- Monitor and evaluate the effectiveness of improvements

- Foster a culture of innovation and continuous learning

10. Describe your experience in using computer-aided design (CAD) and simulation software.

I am proficient in using various CAD and simulation software, including:

- AutoCAD for 2D and 3D design

- SolidWorks for mechanical design and simulation

- ANSYS for fluid dynamics and structural analysis

- Utilized these tools to design and optimize industrial products and processes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Technologist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Technologist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial Technologists are highly skilled professionals who play a vital role in the manufacturing and production industries. Their responsibilities span a wide range of tasks, including:

1. Research and Development

Industrial Technologists conduct research and development to improve existing products and processes, develop new ones, and find ways to optimize production. They may also be involved in creating prototypes and testing new products.

- Conduct research on new materials, processes, and technologies.

- Develop and test new products and processes.

- Create prototypes and evaluate their performance.

2. Process Improvement

Industrial Technologists work to improve the efficiency and productivity of manufacturing processes. They may identify bottlenecks and inefficiencies, develop solutions to problems, and implement new technologies to streamline operations.

- Identify bottlenecks and inefficiencies in manufacturing processes.

- Develop and implement solutions to improve processes.

- Implement new technologies to streamline operations.

3. Quality Control

Industrial Technologists ensure that products meet quality standards by conducting inspections, testing products, and analyzing data. They may also develop and implement quality control systems to prevent defects and ensure product safety.

- Conduct inspections and tests to ensure products meet quality standards.

- Analyze data to identify trends and areas for improvement.

- Develop and implement quality control systems.

4. Equipment Maintenance

Industrial Technologists are responsible for maintaining and repairing equipment used in manufacturing processes. They may perform preventive maintenance, troubleshoot problems, and repair or replace equipment as needed.

- Perform preventive maintenance on equipment.

- Troubleshoot problems and repair equipment.

- Replace equipment as needed.

Interview Tips

Preparing for an interview can be a nerve-wracking experience, but there are things you can do to increase your chances of success. Here are a few tips to help you ace your interview for an Industrial Technologist position:

1. Research the Company

Take some time to research the company you’re interviewing with. This will help you better understand their culture, values, and what they’re looking for in a candidate. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company’s website to learn about their products, services, and culture.

- Read the company’s social media pages to get a sense of their culture and values.

- Check out Glassdoor to see what other candidates have said about their interview experience.

2. Practice Your Answers

One of the best ways to prepare for an interview is to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview. Some common interview questions for Industrial Technologists include:

- Tell me about your experience with research and development.

- What are your strengths and weaknesses as an Industrial Technologist?

- How have you improved the efficiency of a manufacturing process in the past?

- What are your thoughts on the future of manufacturing?

3. Be Enthusiastic

Employers are looking for candidates who are passionate about their work. So be sure to show your enthusiasm for industrial technology during the interview. Talk about your favorite projects and what you’re most excited about in the field. Let the interviewer know that you’re eager to learn and grow, and that you’re passionate about making a difference in the manufacturing industry.

- Share your favorite projects and what you’re most excited about in the field.

- Let the interviewer know that you’re eager to learn and grow.

- Express your passion for making a difference in the manufacturing industry.

4. Ask Questions

Asking questions at the end of the interview shows that you’re interested in the position and the company. It also gives you an opportunity to learn more about the company and the role. Some good questions to ask include:

- What are the biggest challenges facing the manufacturing industry today?

- What are the company’s plans for future growth?

- What is the company’s culture like?

- What are the opportunities for professional development?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Industrial Technologist, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Industrial Technologist positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.