Feeling lost in a sea of interview questions? Landed that dream interview for Inflatable Buildings Laminator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Inflatable Buildings Laminator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

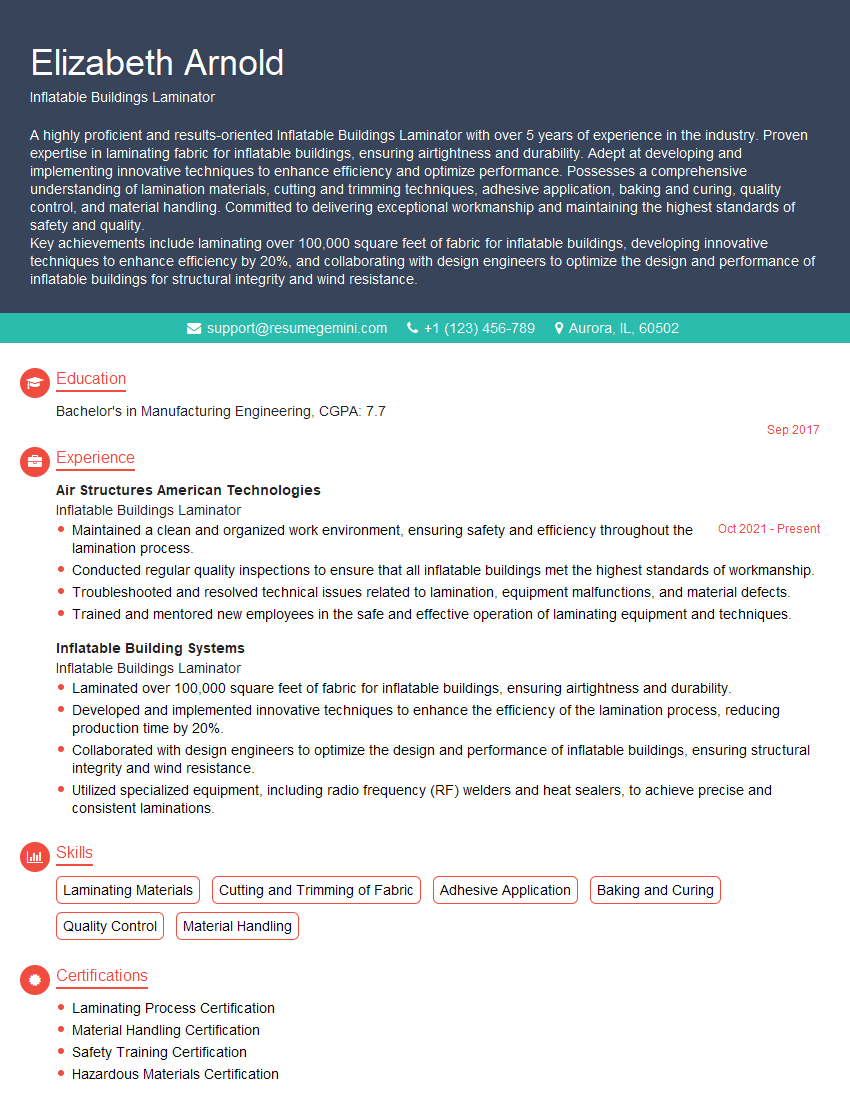

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Inflatable Buildings Laminator

1. Explain the process of laminating inflatable buildings?

The process of laminating inflatable buildings involves several crucial steps to ensure a durable and airtight structure:

- Material Preparation: High-quality, puncture-resistant PVC or TPU fabrics are selected and cut to the desired shape and size.

- Cleaning and Priming: The fabric surfaces are thoroughly cleaned and primed to remove any impurities and enhance adhesion.

- Layering and Bonding: Multiple layers of fabric are carefully overlapped and bonded together using specialized adhesives or heat-sealing techniques.

- Seam Sealing: All seams and joints are meticulously sealed using hot air welding, tape sealing, or other methods to ensure airtightness.

- Quality Control: The finished product undergoes rigorous inspections and testing to verify its strength, durability, and compliance with industry standards.

2. What are the key factors that affect the durability of inflatable buildings?

Material Quality:

- The strength, puncture resistance, and UV stability of the PVC or TPU fabrics used.

Laminating Process:

- The number and thickness of fabric layers.

- The strength and quality of the bonding process.

- The accuracy and precision of seam sealing.

Usage and Maintenance:

- Proper inflation and deflation procedures.

- Regular cleaning and inspection to detect and repair any damage.

- Protection from extreme weather conditions and excessive wear and tear.

3. Describe the different types of inflatable building structures and their applications?

Inflatable building structures come in various types, each tailored to specific applications:

- Temporary Shelters: Event tents, disaster relief shelters, and military field hospitals.

- Storage Buildings: Warehouses, garages, and workshops for temporary or portable storage.

- Sporting Structures: Inflatable sports halls, gymnasiums, and swimming pools.

- Advertising Structures: Giant inflatable balloons, marquees, and trade show displays.

- Custom Structures: Designed for unique applications such as research facilities, medical centers, and exhibition spaces.

4. What are the advantages of using inflatable buildings over traditional structures?

Inflatable buildings offer numerous advantages:

- Quick and Easy Deployment: Can be inflated and set up within a few hours.

- Portability and Mobility: Can be easily transported and relocated as needed.

- Cost-Effective: More economical than permanent structures, especially for temporary or portable applications.

- Energy Efficiency: The airtight construction minimizes heat loss and energy consumption.

- Customizable: Can be designed in various shapes, sizes, and colors to meet specific needs.

5. How do you ensure the safety and stability of inflatable buildings, especially in challenging weather conditions?

Ensuring safety and stability is crucial:

- Proper Anchoring: The structure is securely anchored to the ground using stakes, sandbags, or other appropriate methods.

- Air Pressure Monitoring: Air pressure is constantly monitored and adjusted to maintain structural integrity.

- Wind Mitigation: Design features such as aerodynamic shapes and wind vents help withstand high wind loads.

- Emergency Deflation: Emergency deflation systems allow for quick and controlled deflation in case of extreme weather events.

- Regular Inspection and Maintenance: The structure is periodically inspected and serviced to identify any potential issues or damage.

6. How do you handle repairs and maintenance on inflatable buildings?

Proper repairs and maintenance are essential:

- Minor Repairs: Small punctures or tears can be repaired using specialized repair kits or adhesives.

- Major Repairs: More extensive damage may require professional assessment and repair by experienced technicians.

- Regular Cleaning: The structure is regularly cleaned to remove dirt, debris, and any potential contaminants.

- Inspection and Testing: Periodic inspections and pressure testing help identify any potential issues or weaknesses.

- Training: Staff is trained on proper maintenance and emergency procedures.

7. What are the environmental considerations and sustainability practices related to inflatable buildings?

Environmental sustainability is important:

- Material Sustainability: Choosing eco-friendly materials with low environmental impact.

- Energy Efficiency: The airtight design minimizes energy consumption.

- Waste Reduction: Using recyclable or reusable materials and minimizing waste during production and disposal.

- End-of-Life Management: Developing responsible disposal or recycling plans for inflatable buildings at the end of their lifespan.

8. What is your experience with working with architects and engineers to design and build inflatable buildings?

Collaboration is essential for successful projects:

- Communication: Clear communication and regular coordination with architects and engineers.

- Technical Understanding: Understanding structural design concepts and engineering requirements.

- Compliance: Ensuring that inflatable structures meet all relevant building codes and safety standards.

- Problem-Solving: Collaborating to find innovative solutions to design and engineering challenges.

9. How do you stay up-to-date with the latest advancements and best practices in the field of inflatable building technology?

Continued learning is important:

- Industry Conferences and Events: Attending trade shows and workshops to learn about new technologies and developments.

- Professional Organizations: Joining relevant professional organizations to connect with experts and stay informed.

- Research and Development: Exploring new materials, design concepts, and manufacturing techniques.

- Technical Publications: Reading industry-related publications, journals, and technical papers.

10. What are your career goals and aspirations in the field of inflatable buildings?

Professional growth and development:

- Continued Education: Pursuing advanced certifications or training programs to enhance technical skills.

- Research and Innovation: Contributing to the development and improvement of inflatable building technology.

- Leadership: Assuming a leadership role in project management, research, or business development.

- Mentorship: Guiding and supporting junior professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Inflatable Buildings Laminator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Inflatable Buildings Laminator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Inflatable Buildings Laminator is responsible for laminating and assembling inflatable buildings. This role requires a strong understanding of lamination techniques and a keen eye for detail. Laminators work closely with engineers and designers to ensure that the final product meets specifications and high quality standards.

1. Laminate and assemble inflatable buildings using heat sealing and gluing techniques

This involves joining multiple layers of fabric together to create a strong and durable structure. The laminator must be able to operate a variety of laminating machines and equipment.

- Inspect fabrics and ensure they are properly prepared for lamination

- Select appropriate lamination materials and adhesives

- Operate laminating machines to bond fabric layers together

- Inspect laminated panels for defects and make necessary repairs

- Assemble laminated panels into inflatable buildings

2. Perform quality control inspections on laminated panels and inflatable buildings

The laminator must be able to identify and correct defects in the laminated panels and inflatable buildings. This requires a thorough understanding of the lamination process and the materials used.

- Identify and correct defects in laminated panels and inflatable buildings

- Maintain quality control records and documentation

- Report any quality issues to management

- Participate in quality improvement initiatives

3. Maintain a clean and organized work area

The laminator must maintain a clean and organized work area to ensure the quality of the laminated panels and inflatable buildings. This includes cleaning and maintaining equipment, as well as disposing of materials properly.

- Clean and maintain equipment

- Dispose of materials properly

- Keep work area organized and free of debris

- Adhere to safety regulations

4. Work with engineers and designers to ensure that inflatable buildings meet specifications and quality standards

The laminator must be able to collaborate with engineers and designers to ensure that the inflatable buildings meet the specifications and quality standards. This requires a good understanding of engineering principles and design concepts.

- Review engineering drawings and specifications

- Collaborate with engineers and designers to resolve design issues

- Ensure that inflatable buildings meet specifications and quality standards

- Provide feedback to engineers and designers on lamination process and materials

Interview Tips

Preparing for an interview can be daunting, but there are a few key things you can do to increase your chances of success. By following these tips, you can make a great impression on the interviewer and land the job you want.

1. Research the company and the position

It is important to take the time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job. You can research the company’s website, social media pages, and news articles. You can also read online reviews of the company to get an idea of what it is like to work there.

- Visit the company’s website

- Read the job description carefully

- Research the company’s industry and competitors

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly. You can also prepare answers to questions that are specific to the job you are applying for.

- Tell me about yourself

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the job and that you respect their time.

- Dress in business attire

- Arrive on time for your interview

- Make eye contact with the interviewer

- Be polite and respectful

4. Be enthusiastic and positive

Employers are looking for candidates who are enthusiastic about the job and who are positive about their abilities. Be sure to convey your enthusiasm and positivity during your interview. This will make you more appealing to the interviewer and will increase your chances of getting the job.

- Show your enthusiasm for the job

- Be positive about your abilities

- Be confident in your answers

- Ask questions about the job and the company

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Inflatable Buildings Laminator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Inflatable Buildings Laminator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.