Are you gearing up for a career in Info Print Press Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Info Print Press Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Info Print Press Operator

1. Explain the process of preparing an Info Print Press for printing.

The process of preparing an Info Print Press for printing involves several key steps:

- Power on the press: Ensure that the press is connected to a power source and turned on.

- Load paper: Select the appropriate paper type and size, and load it into the paper tray.

- Set up print job: Create a print job using a software program such as Adobe Acrobat or Microsoft Word.

- Configure press settings: Adjust the press settings, such as paper size, print quality, and orientation, to match the print job specifications.

- Load plates: Insert the printing plates into the appropriate positions on the press.

- Ink up the press: Distribute ink evenly onto the printing plates.

- Calibrate the press: Run a test print to ensure that the press is printing accurately.

2. Describe the different types of paper that can be used on an Info Print Press.

- Offset printing paper: This paper is specifically designed for offset printing processes and provides high-quality results.

- Newsprint: This low-cost paper is commonly used for newspapers and other large-volume printing jobs.

- Coated paper: This paper has a smooth, glossy surface that enhances the appearance of printed images.

- Specialty papers: These papers are designed for specific purposes, such as waterproof paper or magnetic paper.

3. How do you troubleshoot common printing problems on an Info Print Press?

- Paper jams: Check for any obstructions in the paper path, such as torn or wrinkled paper.

- Ink smudging: Ensure that the ink is not too thick or thin, and that the press is calibrated correctly.

- Poor print quality: Inspect the printing plates for damage or wear, and clean the press rollers and blankets.

- Color registration issues: Adjust the press settings to align the colors correctly, and check for any misalignment in the printing plates.

- Machine errors: Refer to the press operator’s manual for troubleshooting specific machine error codes.

4. What maintenance tasks are required for an Info Print Press?

- Regular cleaning: Clean the press rollers, blankets, and ink trays to prevent dirt and paper dust from accumulating.

- Lubrication: Lubricate the press according to the manufacturer’s recommendations to ensure smooth operation.

- Ink level monitoring: Regularly check the ink levels and refill as needed.

- Plate replacement: Replace the printing plates when they become worn or damaged to maintain print quality.

- Software updates: Install software updates to keep the press operating optimally.

5. How do you ensure the safety of yourself and others when operating an Info Print Press?

- Wear appropriate safety gear: This includes safety glasses, gloves, and earplugs.

- Maintain a clean work area: Remove any loose paper, ink spills, or other hazards from the work area.

- Follow lockout/tagout procedures: Disconnect the press from the power source before performing maintenance or repairs.

- Be aware of moving parts: Keep hands and clothing away from moving parts, such as rollers and gears.

- Report any hazards or accidents: Immediately report any unsafe conditions or incidents to a supervisor.

6. What are the key performance indicators (KPIs) that you track for Info Print Press operation?

- Print quality: Monitor the quality of printed materials to ensure they meet customer specifications.

- Productivity: Track the number of prints produced per hour or shift to assess press efficiency.

- Waste reduction: Measure the amount of paper and ink waste generated to identify areas for improvement.

- Machine uptime: Calculate the percentage of time the press is operational to maximize production.

- Customer satisfaction: Monitor customer feedback and resolve any issues promptly to maintain positive relationships.

7. How do you stay updated with the latest advancements in Info Print Press technology?

- Attend industry events: Participate in trade shows and conferences to learn about new products and technologies.

- Read industry publications: Subscribe to magazines and online resources to stay informed about the latest trends.

- Attend manufacturer training: Take advantage of training opportunities offered by the press manufacturer to enhance your skills.

- Network with other professionals: Connect with other Info Print Press operators and share knowledge and best practices.

- Research online: Explore online forums and websites to access technical articles and case studies.

8. Describe your experience in operating and maintaining Info Print Presses.

In my previous role as an Info Print Press Operator, I was responsible for operating and maintaining a fleet of Info Print Presses. My responsibilities included:

- Preparing presses for printing, including loading paper, setting up print jobs, and configuring press settings.

- Troubleshooting and resolving common printing problems, such as paper jams, ink smudging, and color registration issues.

- Performing regular maintenance tasks, such as cleaning, lubrication, and ink level monitoring.

- Ensuring the safety of myself and others while operating the presses.

- Tracking KPIs and implementing process improvements to enhance press efficiency and reduce waste.

9. What are your strengths as an Info Print Press Operator?

- Technical skills: I am proficient in operating and maintaining Info Print Presses, and I have a deep understanding of the printing process.

- Problem-solving skills: I am able to quickly identify and resolve printing problems, minimizing downtime and ensuring production efficiency.

- Attention to detail: I am meticulous in my work, paying close attention to print quality and ensuring that all printed materials meet customer specifications.

- Safety consciousness: I am committed to maintaining a safe work environment and adhering to all safety protocols.

- Teamwork and communication skills: I am a team player and I am able to effectively communicate with colleagues and customers.

10. What are your career goals?

My career goal is to become a lead Info Print Press Operator and eventually move into a management role within the printing industry. I am eager to continue developing my skills and knowledge, and I am confident that my dedication and hard work will enable me to achieve my goals.

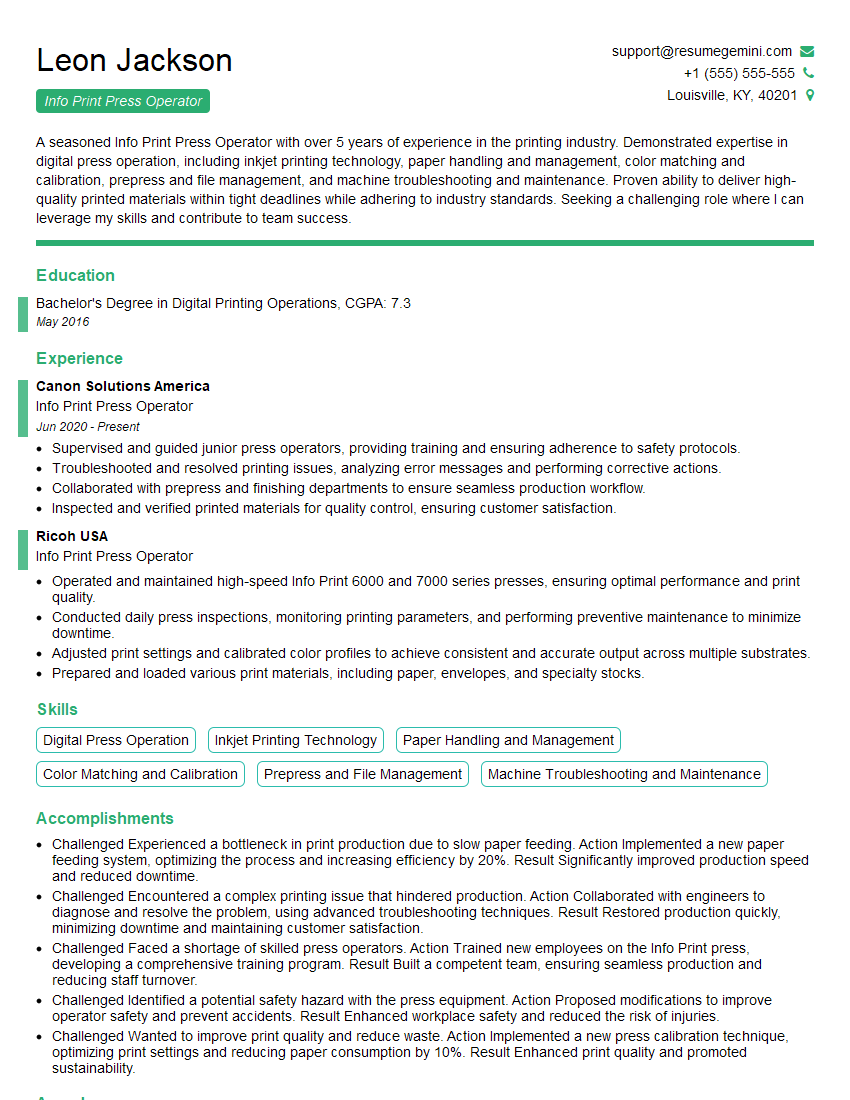

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Info Print Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Info Print Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Info Print Press Operator is responsible for efficiently operating and maintaining high-speed digital printing equipment to produce high-quality printed materials, including brochures, mailers, and marketing collateral.

1. Machine Operation and Maintenance

Setting up and operating digital printing presses to ensure optimal performance and print quality

- Monitoring print jobs, adjusting settings, and troubleshooting any issues

- Performing regular maintenance on printing equipment, including cleaning, lubrication, and repairs

2. Print Quality Control

Inspecting printed materials to ensure they meet quality standards

- Identifying and correcting defects, such as color inaccuracies, registration errors

- Calibrating printing equipment to ensure consistent color reproduction

3. Materials Handling

Loading and unloading paper and other materials from the printing press

- Maintaining an organized and efficient work area

- Following safety procedures when handling materials and operating equipment

4. Customer Service

Interacting with clients to discuss print specifications and requirements

- Providing technical support and answering customer inquiries

- Ensuring customer satisfaction with the printed products

Interview Tips

Preparing for an interview for an Info Print Press Operator position requires a combination of technical knowledge, industry experience, and soft skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry standing.

- Review the job description thoroughly to understand the specific responsibilities and qualifications required

- Research the industry trends and advancements in digital printing technology

2. Highlight Relevant Skills

Emphasize your technical proficiency in operating and maintaining digital printing presses.

- Showcase your experience in print quality control, including color management and defect identification

- Describe your ability to work independently and as part of a team in a fast-paced environment

3. Quantify Your Accomplishments

Use specific examples to demonstrate your impact.

- Provide quantifiable results, such as increasing print quality by a certain percentage or reducing downtime by a specific amount

- Share examples of projects where you implemented new techniques or processes to improve efficiency or quality

4. Demonstrate Your Passion

Express your enthusiasm for the printing industry and your commitment to producing high-quality printed products.

- Share your knowledge of printing techniques and your interest in staying updated with the latest advancements

- Explain why you are interested in working for the specific company and how your skills can contribute to their success

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Info Print Press Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!