Feeling lost in a sea of interview questions? Landed that dream interview for Ingot Car Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ingot Car Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

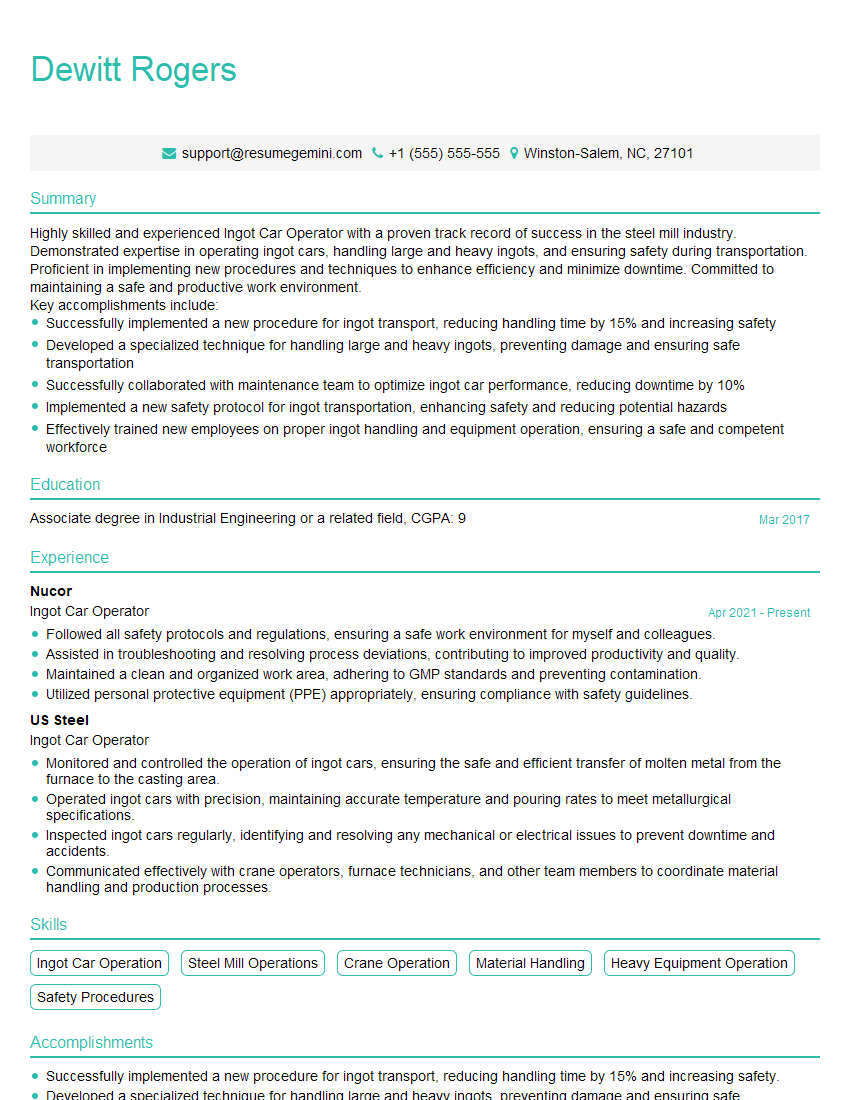

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ingot Car Operator

1. Explain the process of transporting ingots from the casting machine to the storage area?

The process of transporting ingots from the casting machine to the storage area involves several steps:

- The ingots are first allowed to cool and solidify in the casting machine.

- Once the ingots are solid, they are removed from the casting machine using a crane or forklift.

- The ingots are then placed on a conveyor belt or other transport system to be moved to the storage area.

- The ingots are stored in the storage area until they are ready to be shipped to customers.

2. What are the safety precautions that need to be followed when operating an ingot car?

- Make sure the ingot car is in good working condition.

- Wear appropriate safety gear, including gloves, safety glasses, and a hard hat.

- Be aware of your surroundings and other workers in the area.

- Operate the ingot car at a safe speed.

- Be careful not to overload the ingot car.

- Secure the ingots properly to prevent them from falling.

3. How do you troubleshoot common problems that may occur when operating an ingot car?

- If the ingot car is not moving, check the power supply and make sure that the motor is running.

- If the ingot car is moving erratically, check the wheels and tracks for damage.

- If the ingots are not being secured properly, check the clamps and other securing mechanisms.

- If there is a problem with the hydraulic system, check the fluid level and for any leaks.

4. What is the importance of maintaining an ingot car?

- Regular maintenance helps to ensure that the ingot car is in good working condition and safe to operate.

- Maintenance can help to prevent breakdowns and costly repairs.

- Proper maintenance can extend the life of the ingot car.

5. What are the different types of ingot cars?

- There are many different types of ingot cars, each designed for a specific purpose.

- Some of the most common types of ingot cars include:

- Electric ingot cars

- Diesel ingot cars

- Hydraulic ingot cars

- Automated ingot cars

6. What are the advantages and disadvantages of using an electric ingot car?

Advantages:

- Electric ingot cars are more environmentally friendly than diesel ingot cars.

- Electric ingot cars are quieter than diesel ingot cars.

- Electric ingot cars have lower operating costs than diesel ingot cars.

Disadvantages:

- Electric ingot cars have a shorter range than diesel ingot cars.

- Electric ingot cars take longer to charge than diesel ingot cars.

- Electric ingot cars are more expensive to purchase than diesel ingot cars.

7. What are the advantages and disadvantages of using a hydraulic ingot car?

Advantages:

- Hydraulic ingot cars are more powerful than electric ingot cars.

- Hydraulic ingot cars can be used in areas where there is no electricity.

- Hydraulic ingot cars are more durable than electric ingot cars.

Disadvantages:

- Hydraulic ingot cars are more expensive to purchase than electric ingot cars.

- Hydraulic ingot cars require more maintenance than electric ingot cars.

- Hydraulic ingot cars are not as environmentally friendly as electric ingot cars.

8. What are the advantages and disadvantages of using an automated ingot car?

Advantages:

- Automated ingot cars can be used to transport ingots without the need for an operator.

- Automated ingot cars can be programmed to follow a specific route.

- Automated ingot cars can be used to improve safety in the workplace.

Disadvantages:

- Automated ingot cars are more expensive to purchase than manual ingot cars.

- Automated ingot cars require more maintenance than manual ingot cars.

- Automated ingot cars are not as flexible as manual ingot cars.

9. How do you ensure that the ingots are loaded and unloaded safely?

- Use proper lifting techniques.

- Wear appropriate safety gear.

- Be aware of your surroundings.

- Inspect the ingots for damage before loading or unloading.

- Secure the ingots properly to prevent them from falling.

10. What are the different types of ingots that you have experience in handling?

I have experience in handling a variety of ingots, including:

- Steel ingots

- Aluminum ingots

- Copper ingots

- Zinc ingots

- Lead ingots

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ingot Car Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ingot Car Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of Ingot Car Operator

The Ingot Car Operator plays a crucial role in ensuring smooth and efficient production processes within the organization.

1. Equipment Operation and Maintenance

Operate and maintain ingot cars, cranes, and other specialized equipment used in the transportation and handling of ingots.

- Conduct regular inspections and maintenance to ensure equipment is in good working condition.

- Troubleshoot and resolve minor issues with equipment to minimize downtime.

2. Ingot Transportation and Handling

Transport ingots from casting areas to storage facilities or other designated locations.

- Follow established safety protocols and procedures for handling and transporting ingots.

- Monitor and adjust process parameters to ensure ingots are handled safely and efficiently.

3. Production Support

Assist in production activities as required, such as charging furnaces or loading ingots onto casting machines.

- Work in coordination with other team members to ensure a seamless production process.

- Maintain a clean and organized work area to promote safety and productivity.

4. Safety and Compliance

Adhere to all safety regulations and guidelines related to ingot handling and equipment operation.

- Wear appropriate personal protective equipment (PPE) and follow established safety procedures.

- Report any unsafe conditions or practices to supervisors immediately.

Interview Preparation Tips for Ingot Car Operator

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some essential tips to help you ace the interview for an Ingot Car Operator position.

1. Research the Company and Job

Take the time to learn about the company, its industry, and the specific role you’re applying for.

- Visit the company website, read industry news, and explore their social media pages.

- Identify the key responsibilities and qualifications for the position and tailor your resume and answers accordingly.

2. Practice Your Answers

Anticipate common interview questions and prepare clear and concise answers.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Highlight your skills and experience that are most relevant to the job requirements.

3. Demonstrate Your Safety Awareness

Emphasize your understanding of safety regulations and your commitment to following them.

- Provide examples of how you have ensured safety in previous roles.

- Explain your knowledge of PPE and hazard identification.

4. Show Your Mechanical Aptitude

Highlight your ability to operate and maintain equipment.

- Describe your experience with equipment similar to ingot cars or cranes.

- Demonstrate your ability to troubleshoot and resolve common issues.

5. Be Prepared with Questions

Asking thoughtful questions at the end of the interview shows your interest and engagement.

- Prepare questions about the company, the production process, or the role itself.

- This shows that you are enthusiastic about the opportunity and eager to learn more.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ingot Car Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!