Are you gearing up for a career in Ingot Stripper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Ingot Stripper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

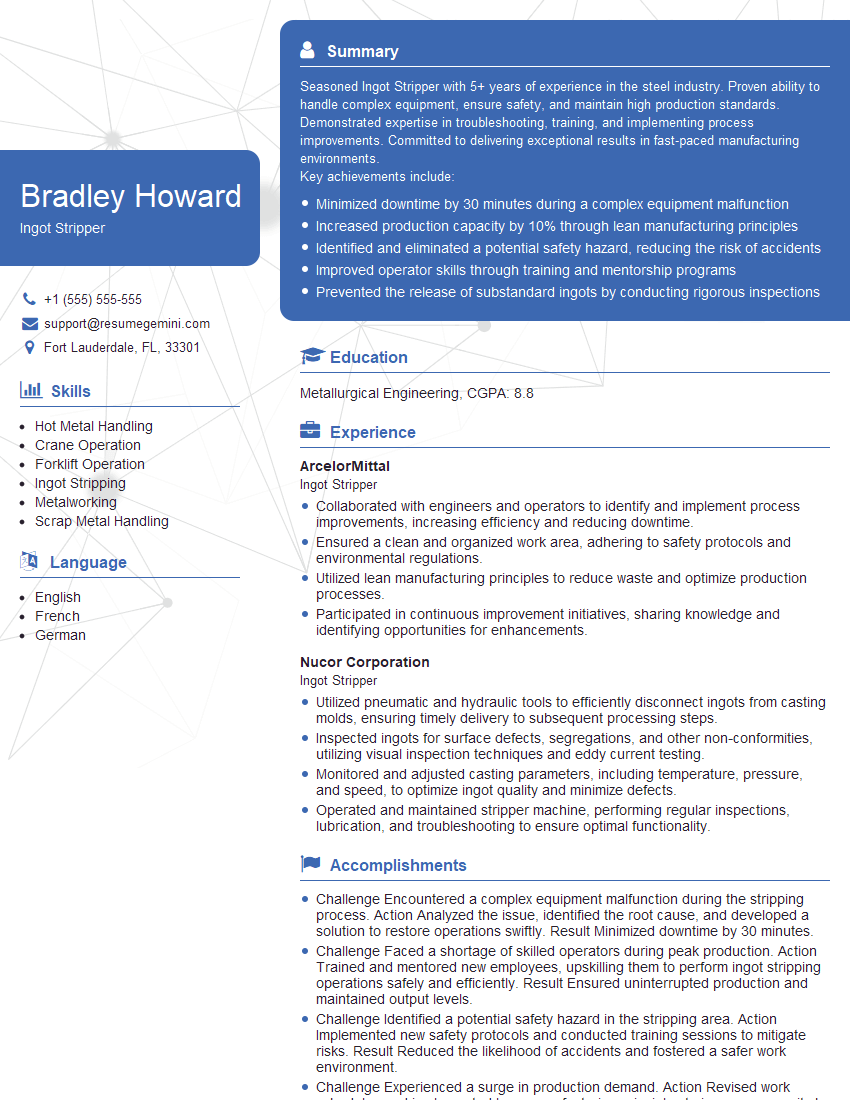

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ingot Stripper

1. What are the key responsibilities of an Ingot Stripper?

- Operate and maintain ingot stripping equipment to remove ingots from molds.

- Monitor and control stripping process parameters to ensure proper operation and safety.

- Inspect ingots for defects and take corrective actions as needed.

- Maintain a clean and safe work area, following all safety protocols.

- Work effectively as part of a team and communicate effectively with colleagues.

2. How do you ensure the safe operation of ingot stripping equipment?

Pre-Operation Checks

- Inspect equipment for any damage or wear.

- Verify that all safety devices are functioning properly.

- Ensure that the work area is clear of any obstacles or hazards.

During Operation

- Follow established operating procedures and safety guidelines.

- Monitor equipment closely and respond promptly to any abnormalities.

- Use proper lifting techniques and personal protective equipment (PPE).

Post-Operation

- Shut down equipment properly and lockout/tagout energy sources.

- Inspect equipment for any issues that may require maintenance or repair.

- Report any incidents or near-misses to the appropriate personnel.

3. What are the common defects that can occur during the ingot stripping process?

- Surface defects: Scratches, dents, cracks, or inclusions on the ingot surface.

- Internal defects: Voids, porosity, or inclusions within the ingot.

- Shape defects: Deviations from the desired ingot shape or dimensions.

- Cooling defects: Non-uniform cooling patterns leading to cracks or other structural issues.

4. How do you handle defective ingots?

- Identify and mark defective ingots according to established procedures.

- Isolate defective ingots from the production line to prevent further contamination.

- Document the defects and notify the appropriate personnel (e.g., quality control, maintenance).

- Follow established procedures for handling and disposition of defective ingots.

5. Describe the maintenance procedures for ingot stripping equipment.

- Daily: Clean and lubricate equipment, inspect for wear or damage.

- Weekly: Perform more detailed inspections, check fluid levels, and calibrate sensors.

- Monthly: Conduct comprehensive maintenance, including overhauling major components and replacing worn parts.

- As needed: Address any unexpected breakdowns or repairs that arise.

6. What are the key safety considerations when working in an ingot stripping area?

- Hot equipment: Ingots and equipment can be extremely hot, requiring proper PPE and handling techniques.

- Heavy loads: Ingots are heavy and can cause injuries if not handled properly.

- Moving machinery: Ingot stripping equipment has moving parts that can be hazardous.

- Electrical hazards: Electrical equipment is used in the stripping process, posing potential risks.

- Slips and falls: Work areas can be wet or slippery, increasing the risk of falls.

7. How do you prioritize tasks and manage multiple responsibilities as an Ingot Stripper?

- Understand plant production schedule and deadlines.

- Identify critical tasks and prioritize them accordingly.

- Delegate tasks to team members as necessary.

- Communicate effectively with colleagues and supervisors.

- Stay organized and maintain a clean and efficient work area.

8. What is your experience with different types of ingot stripping equipment?

- Manual Stripping: Using manual tools to remove ingots from molds.

- Semi-Automatic Stripping: Using machines to partially automate the stripping process.

- Automatic Stripping: Using fully automated machines to remove ingots from molds.

- Specialized Stripping Equipment: Describe any experience with specialized equipment for specific ingot types or processes.

9. How do you stay updated on the latest industry best practices for ingot stripping?

- Attend industry conferences and workshops.

- Read trade publications and technical articles.

- Network with other Ingot Strippers and professionals in the field.

- Seek opportunities for training and professional development.

- Participate in internal company initiatives for knowledge sharing.

10. What are your career goals as an Ingot Stripper?

- Advance to a supervisory or management role within the ingot stripping department.

- Gain expertise in specialized ingot stripping techniques or equipment.

- Contribute to improvements in the ingot stripping process, leading to increased efficiency or safety.

- Become a recognized expert in the field of ingot stripping.

- Share knowledge and experience with colleagues and the wider industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ingot Stripper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ingot Stripper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ingot Strippers are crucial members of metalworking facilities, playing a vital role in the seamless removal of solidified metals from molds, ensuring efficient production processes.

1. Ingot Handling

The ability to safely and skillfully operate forklifts or other heavy equipment is essential to move and position heavy ingots.

- Responsibilities include proper placement of ingots into designated stripping machines.

- They must adhere to safety regulations and follow established operating procedures.

2. Stripping Operations

Ingot Strippers are responsible for operating stripping machines, carefully removing the solidified metal from ingot molds.

- They must ensure that the stripped ingots meet quality standards and are free from defects.

- Proper handling techniques are crucial to prevent damage to both the ingots and the equipment.

3. Machine Maintenance

Ingot Strippers are often responsible for basic maintenance of the stripping machines they operate, ensuring smooth and efficient operations.

- Tasks may include lubrication, cleaning, and minor repairs.

- Regular maintenance helps extend equipment life and prevent costly downtime.

4. Safety and Compliance

Ingot Strippers play a vital role in maintaining a safe work environment, adhering to established safety protocols and regulations.

- They must wear appropriate personal protective equipment (PPE) and follow safe operating procedures.

- Ingot Strippers must be aware of potential hazards, such as hot surfaces, heavy equipment, and molten metal.

Interview Tips

By understanding what interviewers are seeking, candidates can effectively tailor their responses to highlight their abilities and increase their chances of securing the job.

1. Research and Preparation

Ingot Strippers should thoroughly research the company, the industry, and the specific role they are applying for.

- This will enable them to speak intelligently about the company’s products, services, and culture.

- Candidates should also familiarize themselves with the job description, identifying key responsibilities and requirements.

2. Highlight Relevant Skills and Experience

Interviewers will be looking for candidates with the necessary skills and experience to perform the job effectively.

- Ingot Strippers should emphasize their proficiency in operating heavy equipment, handling heavy materials, and adhering to safety protocols.

- Any previous experience in metalworking or manufacturing will be a valuable asset.

3. Demonstrate Safety Consciousness

Safety is paramount in metalworking environments. Candidates should demonstrate a strong understanding of safety procedures and their commitment to maintaining a safe work environment.

- They should provide examples of their safety practices and how they ensure compliance with regulations.

- Interviewers will be impressed by candidates who prioritize safety and have a proven track record of working safely.

4. Ask Thoughtful Questions

Asking insightful questions at the end of the interview shows that the candidate is engaged, interested in the role, and eager to learn more about the company.

- Questions about the company’s growth plans, the team culture, or the future of the industry demonstrate a genuine interest in the organization.

- Candidates should avoid asking generic questions or questions that have already been answered during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ingot Stripper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!