Feeling lost in a sea of interview questions? Landed that dream interview for Ingot Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ingot Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

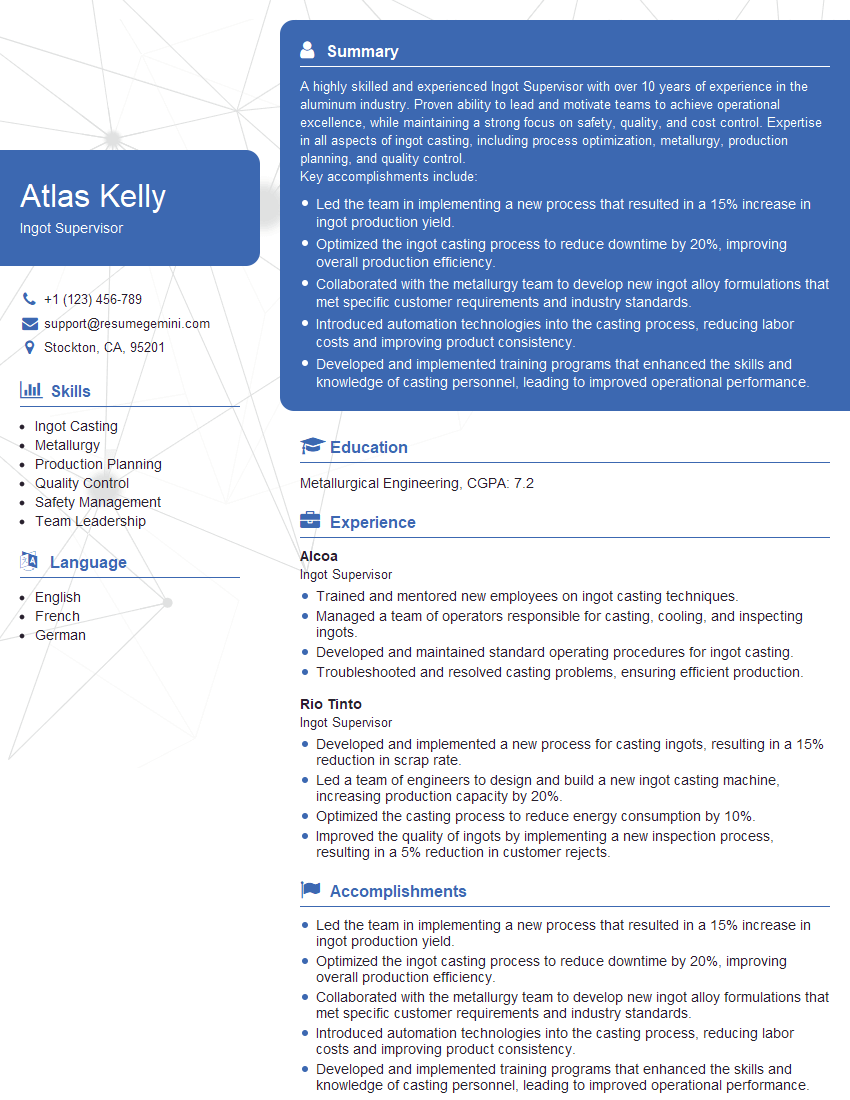

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ingot Supervisor

1. How would you ensure that the ingots produced meet the required quality standards?

To ensure the quality of ingots, I would implement the following measures:

- Establish and maintain a rigorous quality control program that includes regular inspections and testing.

- Use calibrated and certified equipment for all testing and measurement.

- Train and certify all operators on quality control procedures.

- Monitor and track quality data to identify trends and areas for improvement.

- Work closely with the quality assurance department to ensure that all quality standards are met.

2. What are the key safety hazards associated with ingot production, and how would you mitigate them?

Hazards Mitigation

- High temperatures Use personal protective equipment (PPE), ensure proper ventilation, and provide heat shields.

- Molten metal splatter and spills Use PPE, implement containment measures, and train operators on spill response.

- Electrical hazards Ensure proper grounding, use insulated tools, and provide regular electrical safety training.

- Lifting and handling hazards Use proper lifting techniques, equipment, and PPE.

- Noise hazards Implement noise control measures, provide PPE, and conduct regular hearing tests.

3. Describe the role of the Ingot Supervisor in optimizing production efficiency.

As the Ingot Supervisor, I would optimize production efficiency by:

- Monitoring and analyzing production data to identify bottlenecks and areas for improvement.

- Working with the production team to implement process improvements and streamline operations.

- Ensuring that all equipment is properly maintained and calibrated.

- Training and motivating the production team to achieve high levels of performance.

- Implementing lean manufacturing principles and Six Sigma techniques to reduce waste and improve efficiency.

4. How would you manage a team of ingot operators to ensure they are meeting performance targets and maintaining a high level of quality?

To manage the team effectively, I would:

- Set clear performance targets and provide regular feedback to operators.

- Provide training and support to help operators improve their skills and knowledge.

- Foster a positive and collaborative work environment.

- Celebrate successes and recognize achievements.

- Address performance issues promptly and fairly.

5. What are the latest advancements in ingot production technology, and how would you stay up-to-date with these advancements?

To stay up-to-date with the latest advancements, I would:

- Attend industry conferences and workshops.

- Read industry publications and technical journals.

- Network with other ingot production professionals.

- Research and evaluate new technologies.

- Attend training courses on new technologies.

6. What are the key performance indicators (KPIs) that you would use to measure the success of the ingot production operation?

- Production volume

- Quality yield

- Production efficiency

- Safety record

- Cost per unit produced

7. What steps would you take to continuously improve the ingot production process?

To continuously improve the process, I would:

- Establish a team to identify and address areas for improvement.

- Use data analysis to identify trends and patterns.

- Implement lean manufacturing principles and Six Sigma techniques.

- Involve operators in the improvement process.

- Benchmark against industry best practices.

8. Describe a challenging situation you faced in a previous role and how you overcame it.

In a previous role, I was responsible for managing a team of ingot operators who were struggling to meet production targets. After analyzing the situation, I identified several areas for improvement, including:

- Inadequate training

- Poor equipment maintenance

- Inefficient work processes

I worked with the team to address these issues by implementing the following measures:

- Developed and delivered comprehensive training programs.

- Established a rigorous equipment maintenance schedule.

- Streamlined work processes and eliminated bottlenecks.

As a result of these improvements, the team was able to significantly increase production output and meet all customer requirements.

9. What are your strengths and weaknesses as an Ingot Supervisor?

Strengths

- In-depth knowledge of ingot production processes and technologies.

- Proven ability to manage and motivate a team.

- Excellent communication and interpersonal skills.

- Strong problem-solving and decision-making abilities.

- Commitment to safety and quality.

Weaknesses

- Limited experience in certain aspects of ingot production, such as advanced automation.

- Tendency to be detail-oriented, which can sometimes slow down decision-making.

- Lack of experience in managing a large team.

10. Why are you interested in working as an Ingot Supervisor with our company?

I am interested in working as an Ingot Supervisor with your company because I am impressed by your commitment to quality, innovation, and sustainability. I believe that my skills and experience would be a valuable asset to your team, and I am eager to contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ingot Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ingot Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Ingot Supervisor plays a pivotal role in overseeing the production of metal ingots, ensuring adherence to quality standards, production targets, and operational safety. Their primary duties encompass:

1. Production Management

Directing and coordinating the production process, including scheduling shifts, assigning tasks, and monitoring progress to meet production goals.

- Optimizing production efficiency by identifying and implementing process improvements.

- Ensuring compliance with production specifications, quality control measures, and safety protocols.

2. Quality Control and Assurance

Monitoring and maintaining the quality of ingots produced, ensuring they meet customer requirements and industry standards.

- Conducting regular quality inspections and coordinating corrective actions to mitigate defects.

- Analyzing production data and implementing quality improvement initiatives.

3. Equipment Maintenance and Operation

Supervising the maintenance and operation of production equipment, ensuring it is in optimal condition for efficient production.

- Scheduling and overseeing equipment maintenance and repairs.

- Training and supervising operators on proper equipment operation and safety procedures.

4. Team Management and Development

Leading, motivating, and developing a team of operators and technicians, fostering a positive and productive work environment.

- Setting performance goals, providing feedback, and conducting performance evaluations.

- Identifying training needs and arranging training opportunities for team members.

Interview Tips

To ace an interview for an Ingot Supervisor position, prepare thoroughly and showcase your expertise. Here are some helpful tips:

1. Research the Company and Role

Demonstrate your interest and enthusiasm by researching the company’s operations, industry trends, and the specific job requirements. This knowledge will help you tailor your answers to the interviewer’s questions.

- Visit the company’s website, read industry publications, and network with professionals in the field.

- Carefully review the job description to identify the key responsibilities and qualifications required for the role.

2. Highlight Your Relevant Experience

Emphasize your experience and skills that directly align with the job requirements. Quantify your accomplishments and provide specific examples of your contributions.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and demonstrate your problem-solving abilities.

- Showcase your expertise in production management, quality control, equipment maintenance, and team leadership.

3. Prepare for Technical Questions

Anticipate technical questions related to ingot production processes, quality control techniques, and equipment operation. Be prepared to discuss your understanding and experience in these areas.

- Review common metallurgical processes, such as casting, rolling, and heat treatment.

- Familiarize yourself with quality control procedures, including inspection methods and statistical analysis.

4. Practice Your Answers

Rehearse your responses to potential interview questions, especially those related to your experience and qualifications. Practice in front of a mirror or with a friend or family member to gain confidence and improve your delivery.

- Prepare answers to common interview questions, such as “Why are you interested in this role?” and “What are your strengths and weaknesses?”

- Craft specific examples that demonstrate your skills and how they align with the job requirements.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. Be polite, respectful, and maintain eye contact with the interviewer.

- Choose business attire that is clean, pressed, and fits well.

- Be punctual and allow ample time for travel and parking.

Next Step:

Now that you’re armed with the knowledge of Ingot Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Ingot Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini