Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Injection Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Injection Machine Operator so you can tailor your answers to impress potential employers.

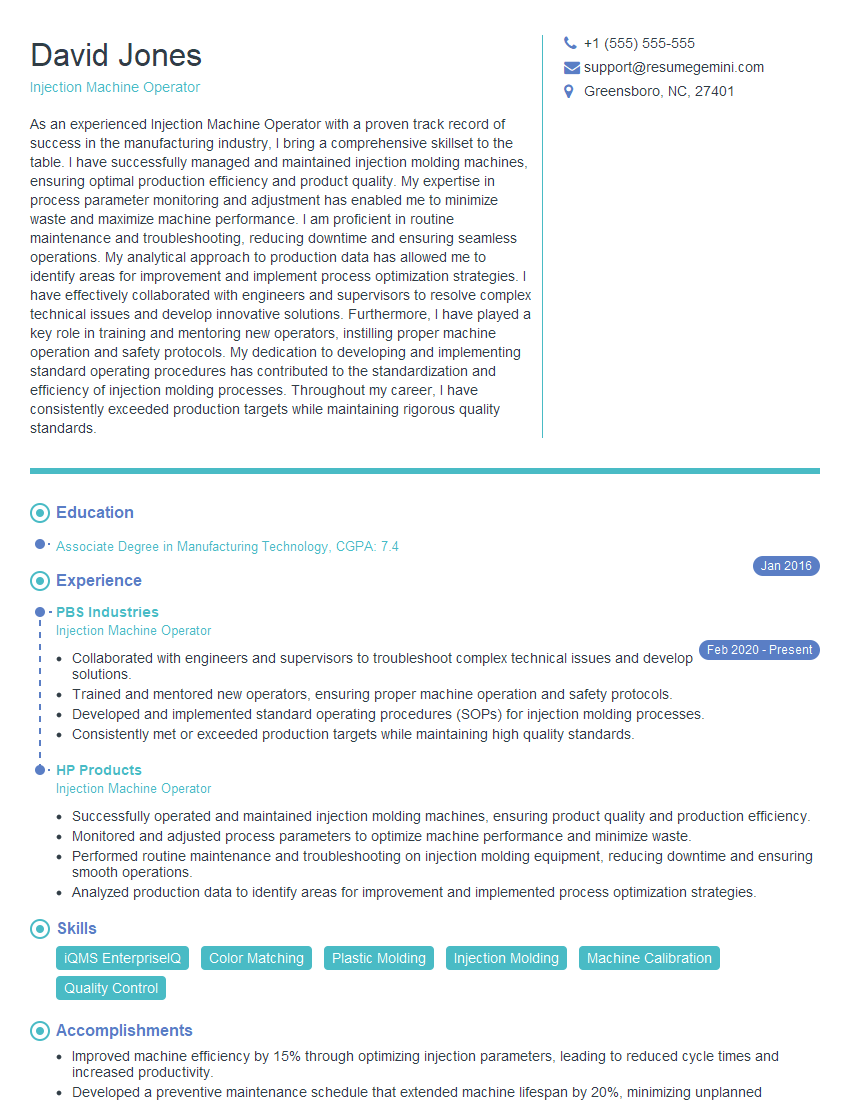

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Injection Machine Operator

1. What types of injection molding machines have you operated in the past?

– Electrical – Hybrid – Hydraulic

2. Can you describe the different types of plastic materials you have worked with?

Thermoplastics

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

Thermosets

- Polyester

- Epoxy

- Phenolic

3. What is the difference between a cold runner and a hot runner system?

– Cold runners are used for shorter production runs and simpler parts, while hot runners are used for longer production runs and more complex parts. – Cold runners are less expensive to set up, but they can lead to more waste and can be more difficult to control. – Hot runners are more expensive to set up, but they can lead to less waste and can be easier to control.

4. What is the purpose of a mold release agent?

– Mold release agents are used to prevent the plastic from sticking to the mold. – They can also help to improve the surface finish of the molded part.

5. What are some common defects that can occur during injection molding?

- Flash

- Sink marks

- Voids

- Weld lines

6. How do you troubleshoot an injection molding machine?

– First, identify the problem. – Then, determine the cause of the problem. – Finally, take corrective action to solve the problem.

7. What are some tips for optimizing the injection molding process?

- Use the correct machine for the job.

- Use the correct mold for the job.

- Use the correct plastic material for the job.

- Use the correct process parameters for the job.

- Monitor the process closely.

8. What are some recent advances in injection molding technology?

- Multi-component injection molding

- Micro-injection molding

- Hybrid injection molding

9. How do you stay up-to-date on the latest injection molding technologies?

- Attend trade shows and conferences.

- Read industry publications.

- Talk to other injection molding professionals.

10. What are your career goals?

– I would like to learn more about injection molding and eventually become a supervisor or manager. – I am also interested in developing new products and processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Injection Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Injection Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Injection Machine Operators are responsible for the day-to-day operation and maintenance of injection molding machines, which produce plastic parts using a mold.

1. Machine Operation

Operate injection molding machines to produce plastic parts according to specifications.

- Set up and adjust machine parameters, such as temperature, pressure, and cycle time.

- Monitor machine operation and make adjustments as needed to ensure quality and efficiency.

2. Molding Process

Prepare and maintain molds used in the injection molding process.

- Inspect molds for damage and wear, and perform necessary maintenance.

- Install and remove molds from machines, and ensure proper alignment.

3. Quality Control

Inspect finished plastic parts for defects and ensure they meet quality standards.

- Use measuring tools and gauges to verify part dimensions and tolerances.

- Identify and correct any defects in the molding process.

4. Safety and Maintenance

Maintain a safe and clean work environment.

- Follow safety protocols and wear appropriate personal protective equipment.

- Perform routine maintenance on machines and equipment, including lubrication, cleaning, and repairs.

Interview Tips

Preparation is key to acing any interview. Here are some tips to help you prepare for an Injection Machine Operator interview:

1. Research the Company and Role

Familiarize yourself with the company’s history, values, and products. Research the specific role you’re applying for, including the key responsibilities and qualifications.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on trends.

2. Practice Your Answers

Take time to think about common interview questions and prepare thoughtful responses. Practice answering questions using the STAR method (Situation, Task, Action, Result).

- Example Outline:

- Situation: Describe a time you faced a challenge operating an injection molding machine.

- Task: Explain the steps you took to resolve the issue.

- Action: Highlight the specific actions you performed.

- Result: Quantify the impact of your actions.

3. Highlight Your Skills and Experience

Emphasize the skills and experience that make you a suitable candidate for the role.

- Quantify your accomplishments whenever possible. For example, instead of saying “I operated injection molding machines,” say “I operated 5 injection molding machines, producing over 100,000 plastic parts per day.”

- Use keywords from the job description in your resume and interview responses.

4. Be Professional and Enthusiastic

Dress appropriately for the interview and arrive on time. Maintain eye contact, speak clearly, and demonstrate a positive attitude throughout the interview.

- Show enthusiasm for the role and the company.

- Thank the interviewer for their time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Injection Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!