Are you gearing up for an interview for a Injection Mold Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Injection Mold Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

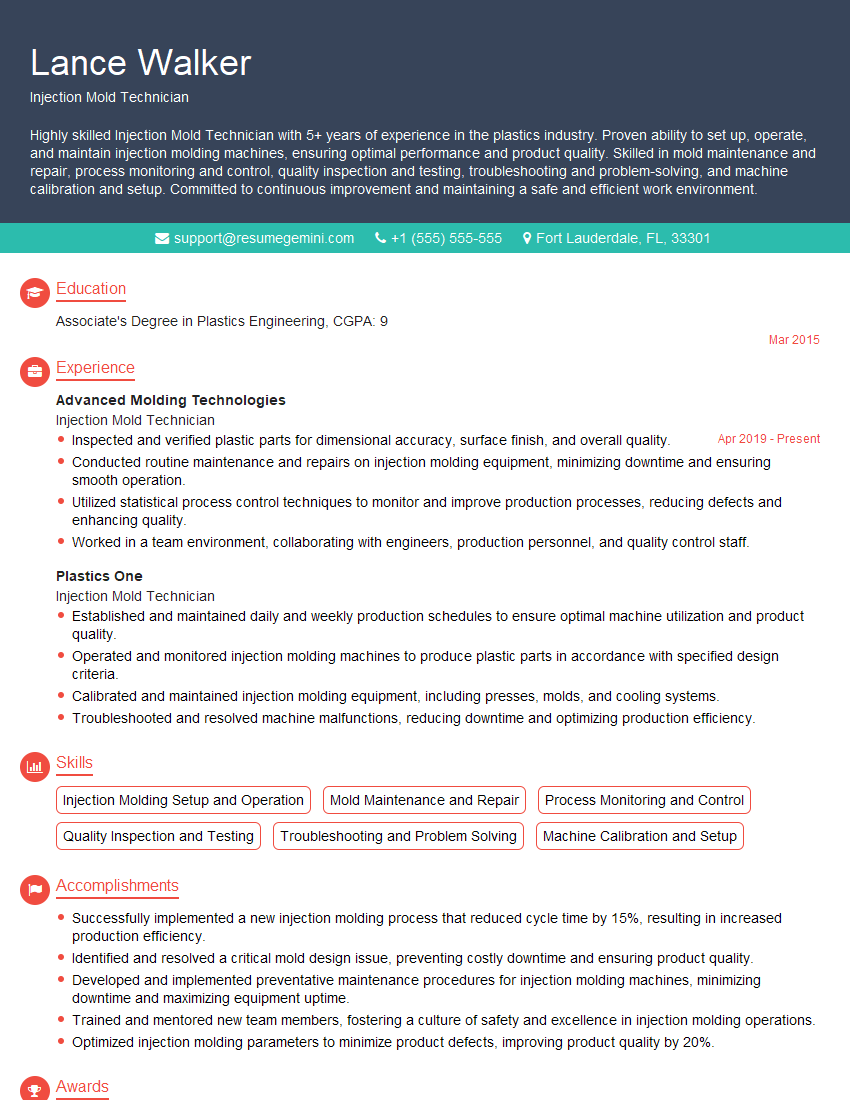

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Injection Mold Technician

1. Describe the injection molding process in detail and mention the key parameters that need to be controlled?

- Raw materials are fed into a hopper and melted by heat and pressure.

- The molten plastic is injected into a mold cavity where it is shaped and cooled.

- The molded part is ejected from the mold and inspected.

- Key parameters that need to be controlled include temperature, pressure, flow rate, and cycle time.

2. How do you ensure that the injection molded parts meet the desired quality standards?

- Adhere to the established quality standards and specifications.

- Conduct regular inspections throughout the production process.

- Use statistical process control (SPC) techniques to monitor and control the critical parameters.

- Document all quality checks and inspections.

3. What is the role of preventive maintenance in injection molding?

Predictive Maintenance:

- Prevent unexpected breakdowns and ensure optimal performance.

- Regularly inspect and service equipment.

- Replace worn or damaged parts before they fail.

Proactive Maintenance:

- Gather data and analyze trends to identify potential issues.

- Schedule maintenance activities based on equipment usage and condition.

4. Describe the troubleshooting process you follow when an injection molding machine malfunctions?

- Identify the problem and gather relevant information.

- Check for obvious causes such as leaks, blockages, or electrical faults.

- Consult technical manuals and documentation.

- Use diagnostic tools to pinpoint the issue.

- Implement corrective actions and verify the solution.

5. How do you optimize the injection molding process for efficiency and productivity?

- Review and refine process parameters to minimize cycle time.

- Implement automation to reduce manual labor and increase throughput.

- Use mold cooling techniques to improve cycle times.

- Regularly monitor and adjust process parameters to maintain optimal performance.

6. What is the importance of material selection in injection molding?

- Material properties such as strength, flexibility, and thermal resistance impact the final part’s performance.

- Consider factors such as cost, availability, and environmental impact.

- Consult with material suppliers for technical advice and recommendations.

7. How do you handle defects in injection molded parts?

- Identify the root cause of the defects.

- Implement corrective actions to eliminate the defects.

- Document the defects and corrective actions for future reference.

- Communicate with the production team to prevent similar defects in the future.

8. What is the role of mold design in injection molding?

- Mold design influences the quality, efficiency, and cost of the injection molding process.

- Factors to consider include part geometry, material flow, and cooling requirements.

- Collaborate with mold designers to optimize mold design for specific applications.

9. How do you stay up-to-date with the latest advancements in injection molding technology?

- Attend industry trade shows and conferences.

- Read technical literature and journals.

- Network with other injection molding professionals.

- Engage in continuing education and training programs.

10. Provide an example of a successful injection molding project you have worked on and highlight your contributions?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Injection Mold Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Injection Mold Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Injection Mold Technicians play a crucial role in ensuring the efficient production of plastic parts through injection molding. Their responsibilities encompass:

1. Machine Setup and Operation

Preparing and setting up injection molding machines, ensuring they are calibrated and operating within specifications.

- Monitoring and controlling machine settings, including temperature, pressure, and cycle time.

- Loading and unloading raw materials and finished products.

2. Mold Maintenance and Troubleshooting

Maintaining and repairing injection molds, including cleaning, replacing worn parts, and troubleshooting issues.

- Inspecting molds for damage or defects and making necessary adjustments.

- Troubleshooting injection molding problems, such as part defects, flow issues, and machine malfunctions.

3. Quality Inspection and Control

Inspecting molded parts to ensure they meet quality standards, and taking corrective actions if necessary.

- Using measuring devices and gauges to verify part dimensions and tolerances.

- Identifying and resolving defects, such as surface imperfections, flash, or shrinkage.

4. Process Optimization and Improvement

Analyzing production data and identifying opportunities for process optimization and improvement.

- Working with engineers and production teams to implement changes that enhance efficiency or reduce defects.

- Staying abreast of new technologies and industry best practices to improve molding processes.

Interview Tips

Preparing thoroughly for an Injection Mold Technician interview is essential to showcase your skills and increase your chances of success. Consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company, its products, and its values. Research the specific role and its responsibilities.

- Visit the company website and read industry publications.

- Connect with current or former employees on LinkedIn to gain insights into the company culture and work environment.

2. Highlight Relevant Experience and Skills

Emphasize your hands-on experience in injection molding, mold maintenance, and quality control. Quantify your accomplishments with specific examples.

- Discuss successful projects where you improved production efficiency or reduced defects.

- Demonstrate your ability to troubleshoot and resolve complex molding issues.

3.Showcase Your Technical Knowledge

Be prepared to discuss technical aspects of injection molding, such as:

- Types of injection molding machines and their applications

- Common thermoplastic materials and their properties

- Mold design and construction considerations

- Quality control techniques and standards

4. Practice Your Communication Skills

Prepare for behavioral interview questions that assess your teamwork, problem-solving, and communication abilities.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Practice answering questions with confidence and enthusiasm.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Injection Mold Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Injection Mold Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.