Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Injection Mold Tooling Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

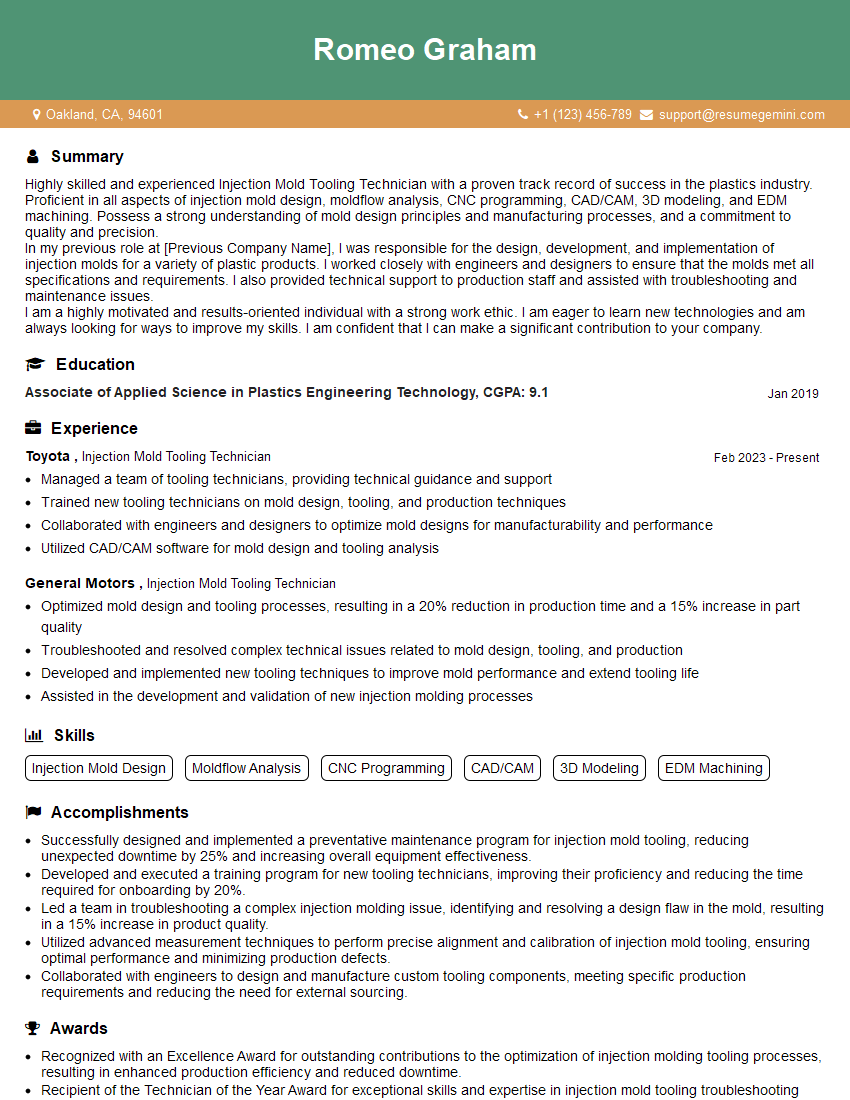

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Injection Mold Tooling Technician

1. Explain the process of designing an injection mold tool?

The process of designing an injection mold tool involves several key steps:

- Part Design Analysis: Understanding the part’s geometry, functional requirements, and material properties.

- Mold Concept Generation: Developing initial ideas for the mold design, including gating, runner, and cooling systems.

- Mold Design: Creating detailed 3D models of the mold components, ensuring proper part fit and moldability.

- Mold Simulation: Using software to analyze the mold design for potential defects, such as short shots, flash, or sink marks.

- Mold Optimization: Refining the mold design based on simulation results to improve part quality and optimize cycle times.

2. What are the different types of injection molds?

Cold Runner Molds

- Non-reusable runners that are cut off from the part after injection.

- Used for low-volume production and prototyping.

Hot Runner Molds

- Heated runners that keep plastic molten, allowing for continuous injection.

- Suitable for high-volume production and complex parts.

3-Plate Molds

- Have a separate ejector plate to push the part out of the mold.

- Used for parts with deep pockets or undercuts.

Stack Molds

- Multiple cavities stacked vertically, increasing production efficiency.

- Suitable for small, simple parts.

3. What materials are used to make injection mold tools?

- Tool Steels: P20, H13, S7 for high hardness and durability.

- Aluminum: 6061, 7075 for lightweight molds and faster machining.

- Beryllium Copper: High conductivity and wear resistance for molds with fine details.

- Stainless Steel: 420, 440 for corrosion resistance and strength.

4. How do you measure and control the temperature of an injection mold?

- Thermocouples: Embedded sensors that measure mold temperature directly.

- Infrared Thermometers: Non-contact devices that measure surface temperature.

- Control Units: Regulate mold temperature using heating and cooling systems.

- Closed-Loop Control: Uses feedback from thermocouples to adjust heat input and maintain precise temperature.

5. Explain the importance of ejector pin placement in injection mold design?

- Part Ejection: Pins push the part out of the mold after injection.

- Part Quality: Proper placement prevents part deformation or damage.

- Cycle Time: Optimizing pin placement can reduce ejection time.

- Mold Maintenance: Pins should be accessible for easy cleaning and replacement.

6. How do you troubleshoot common injection molding defects?

- Short Shots: Insufficient plastic flow; check injection pressure, material viscosity, or gate design.

- Flash: Plastic leaking from mold gaps; inspect parting line seals, runner system, or mold wear.

- Sink Marks: Dents in the part; adjust packing pressure, cooling time, or material crystallization.

- Warping: Uneven cooling or material shrinkage; modify mold design for balanced cooling, reduce injection speed, or use reinforcing ribs.

7. Describe the role of mold polishing in injection molding?

- Surface Finish: Polishing improves part surface quality and reduces roughness.

- Part Release: A polished surface allows for easier part ejection.

- Mold Maintenance: Polishing removes mold imperfections and extends mold life.

- Flow Optimization: Polishing runner and gate surfaces can reduce flow resistance and improve filling.

8. How do you maintain and calibrate an injection mold?

- Regular Cleaning: Remove plastic residue, dust, and debris.

- Inspection: Check for wear, damage, or corrosion on mold components.

- Calibration: Ensure mold dimensions, clamping force, and temperature control are accurate.

- Documentation: Maintain records of inspections, maintenance, and calibration.

9. Explain how you use CAD/CAM software in injection mold design?

- Part Design: Create 3D models of the part to be molded.

- Mold Design: Design mold components, including cavities, cores, and runner systems.

- Simulation: Analyze mold designs using simulation software to predict part quality and moldability.

- Toolpath Generation: Generate code for CNC machines to manufacture mold components.

10. Describe your experience with different types of injection molding machines?

I have worked with various injection molding machines, including:

- Clamping Force: 50-500 tons or more.

- Injection Capacity: 1-10 ounces or more.

- Tie Bar Spacing: Different sizes to accommodate mold dimensions.

- Control Systems: PLC, HMI, and closed-loop temperature control.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Injection Mold Tooling Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Injection Mold Tooling Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Injection Mold Tooling Technician is responsible for building and maintaining injection molds. These molds are used to create plastic parts for a variety of industries, including automotive, medical, and electronics. The key job responsibilities of an Injection Mold Tooling Technician include:

1. Build and maintain injection molds

Injection Mold Tooling Technicians use a variety of tools and machines to build and maintain injection molds. These tools and machines include lathes, mills, grinders, and coordinate measuring machines (CMMs). Technicians must be able to read and interpret blueprints and technical drawings in order to create and maintain molds that meet the required specifications.

2. Troubleshoot and repair molds

Injection molds can malfunction for a variety of reasons. Injection Mold Tooling Technicians must be able to troubleshoot and repair molds in order to keep them running smoothly. This may involve replacing worn parts, repairing damaged components, or adjusting the mold settings.

3. Inspect and test molds

Injection Mold Tooling Technicians must inspect and test molds to ensure that they are producing parts that meet the required specifications. This may involve using CMMs to measure the dimensions of parts, or using other inspection methods to check for defects.

4. Work with other team members

Injection Mold Tooling Technicians often work with other team members, such as engineers, mold designers, and production staff. They must be able to communicate effectively with other team members and work together to solve problems.

Interview Tips

To prepare for an interview for an Injection Mold Tooling Technician position, you should:

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and to tailor your answers to the specific requirements of the position.

2. Practice your answers to common interview questions

There are a number of common interview questions that you will likely be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as an Injection Mold Tooling Technician. Be prepared to talk about your experience in building and maintaining molds, troubleshooting and repairing molds, and inspecting and testing molds. You should also be prepared to discuss your skills in using different tools and machines, and your ability to work with other team members.

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic and positive about working as an Injection Mold Tooling Technician. Show the interviewer that you are passionate about your work and that you are eager to learn and grow in the field.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Injection Mold Tooling Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.