Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Injection Molding Machine Offbearer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

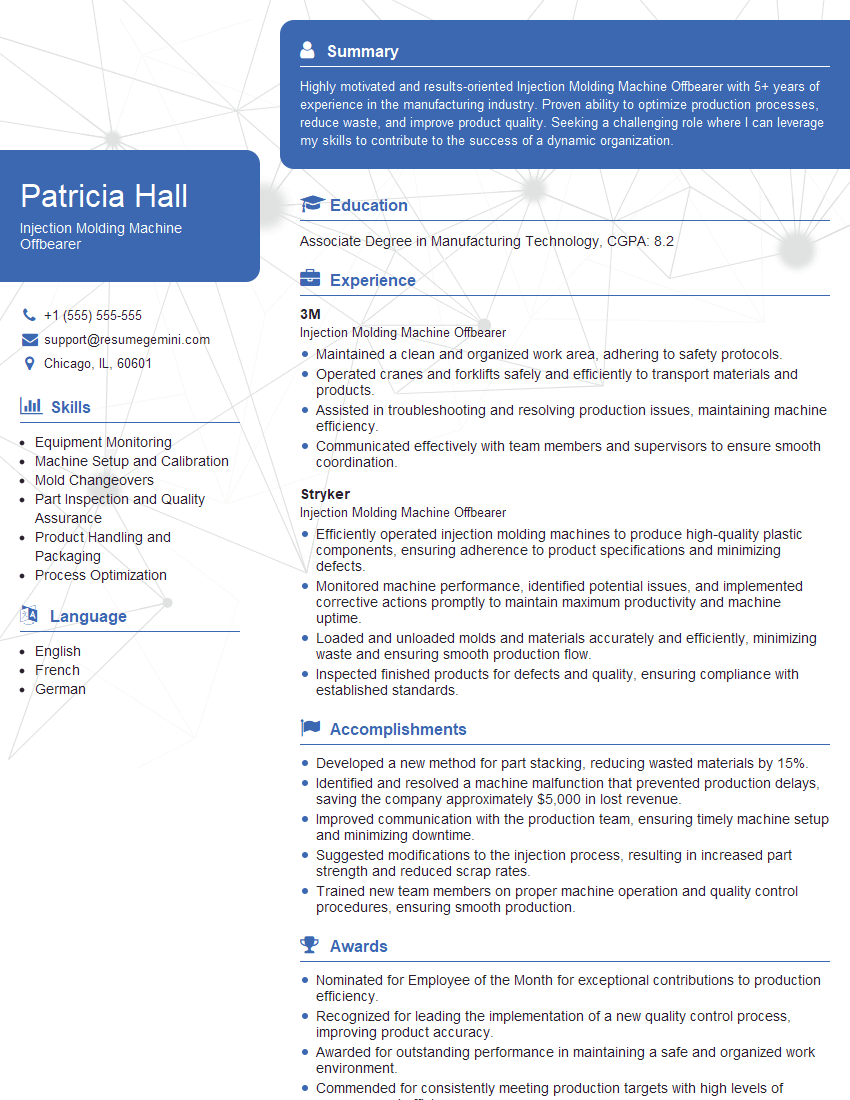

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Injection Molding Machine Offbearer

1. What safety precautions do you follow while operating and maintaining injection molding machines?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Lock out and tag out the machine before performing any maintenance or repairs.

- Follow established operating procedures and keep the work area clean and organized.

- Be aware of potential hazards, such as moving parts, hot surfaces, and electrical currents.

- Report any unsafe conditions or injuries immediately.

2. How do you adjust and maintain the temperature of the injection molding machine and mold?

Temperature Adjustment

- Monitor the temperature of the barrel, nozzle, and mold using thermocouples.

- Adjust temperature settings on the control panel to achieve the desired melt and mold temperatures.

Maintenance

- Clean thermocouples and heating elements regularly to ensure accurate temperature readings.

- Inspect heating elements and wiring for damage or wear.

- Perform preventive maintenance checks on temperature control systems to identify and resolve potential issues.

3. How do you troubleshoot and resolve common injection molding defects such as short shots, flash, or warpage?

- Identify the defect and determine its potential causes.

- Check for machine settings, mold design issues, or material properties that may contribute to the defect.

- Make adjustments to machine parameters, such as injection pressure, injection speed, or hold time.

- Modify mold design or gate location to improve flow and prevent defects.

- Evaluate material properties and adjust processing conditions to optimize melt flow and reduce defects.

4. How do you ensure the production efficiency and quality of injection-molded products?

- Monitor machine performance and output rates to identify process variations.

- Inspect molded parts regularly for defects and dimensional accuracy.

- Make adjustments to machine settings or mold design to improve part quality and reduce waste.

- Implement quality control measures and record production data for traceability and continuous improvement.

- Collaborate with other team members to identify and resolve production bottlenecks or issues.

5. What is the importance of proper mold setup and part ejection for successful injection molding?

- Mold Setup:

- Ensures proper alignment and clamping of the mold halves.

- Prevents mold damage and part defects due to misalignment.

- Part Ejection:

- Facilitates the removal of molded parts from the mold cavity.

- Prevents part damage or deformation during ejection.

- Ensures efficient production by reducing cycle times.

6. How do you handle and store injection molding materials to maintain their quality and prevent contamination?

- Store materials in a clean and dry environment.

- Properly seal containers to prevent moisture absorption.

- Use appropriate handling equipment to avoid material damage.

- Follow manufacturer’s recommendations for material storage and handling.

- Monitor material inventory and rotate stock to ensure freshness.

7. What is your experience in setting up and operating auxiliary equipment such as conveyors, chillers, or robots in an injection molding process?

- Describe specific types of auxiliary equipment you have worked with.

- Explain your role in setting up, operating, and maintaining the equipment.

- Highlight your understanding of how these systems support the injection molding process.

- Provide examples of how you troubleshoot and resolve issues related to auxiliary equipment.

8. How do you stay updated on the latest advancements in injection molding technology and best practices?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Consult with equipment manufacturers and suppliers.

- Explore online resources and forums.

- Network with other professionals in the field.

9. What are your strengths and weaknesses in relation to the role of an Injection Molding Machine Offbearer?

Strengths:

- Attention to detail and quality.

- Strong work ethic and ability to handle physical demands.

- Basic understanding of injection molding principles.

- Experience with handling and storing materials.

Weaknesses:

- Limited experience with advanced injection molding techniques.

- Need for more training on specific equipment and processes.

10. What motivates you to succeed in this role and contribute to our company?

- Passion for manufacturing and injection molding.

- Desire to learn and grow within the industry.

- Commitment to quality and efficiency.

- Teamwork and collaboration spirit.

- Opportunity to make a meaningful contribution to the company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Injection Molding Machine Offbearer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Injection Molding Machine Offbearer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Injection Molding Machine Offbearer is primarily responsible for assisting in the efficient operation of injection molding machines in a manufacturing environment.

1. Machine Operation and Monitoring

Operate injection molding machines according to established procedures and specifications.

- Set up and adjust machine parameters, such as mold temperature, pressure, and injection speed.

- Monitor machine performance and identify potential issues.

2. Part Removal and Inspection

Remove finished parts from the molds and inspect them for defects.

- Use inspection tools and gauges to ensure parts meet quality standards.

- Identify and report any defects or inconsistencies to the appropriate personnel.

3. Material Handling

Handle and transport raw materials, such as pellets or powders, to feed into the machines.

- Ensure timely delivery of materials to minimize downtime.

- Maintain a clean and organized work area.

4. Maintenance and Troubleshooting

Perform basic maintenance and troubleshooting on injection molding machines.

- Identify and resolve minor issues, such as clogged nozzles or jammed parts.

- Report any major breakdowns to the maintenance team.

5. Safety and Compliance

Follow all safety regulations and procedures, including wearing appropriate personal protective equipment.

- Maintain a clean and safe work environment.

- Report any safety hazards or non-compliance to supervisors.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for an Injection Molding Machine Offbearer position:

1. Research the Role and Company

Familiarize yourself with the specific job description and the company’s industry and operations.

- Visit the company’s website and social media pages to learn about their culture and values.

- Read industry publications and articles to stay informed about the latest trends and technologies.

2. Highlight Your Relevant Experience and Skills

Emphasize your experience in operating injection molding machines and handling materials.

- Quantify your achievements whenever possible, using specific numbers and metrics.

- Be prepared to discuss your knowledge of the machine’s components, troubleshoot common issues, and maintain a safe work environment.

3. Demonstrate Your Attention to Detail

Injection molding requires precision and attention to detail. Highlight your ability to follow instructions accurately and identify potential defects.

- Describe instances where you successfully inspected finished parts and resolved quality issues.

- Explain how you maintain a clean and organized work area to prevent accidents and ensure machine efficiency.

4. Prepare Questions for the Interviewers

Asking thoughtful questions shows that you’re engaged and interested in the role. Prepare questions about the company’s production processes, safety protocols, and opportunities for career growth.

- Inquire about the company’s investment in training and development programs.

- Ask about the typical career path for Injection Molding Machine Offbearers within the organization.

Next Step:

Now that you’re armed with the knowledge of Injection Molding Machine Offbearer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Injection Molding Machine Offbearer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini