Feeling lost in a sea of interview questions? Landed that dream interview for Injection Molding Machine Setter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Injection Molding Machine Setter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

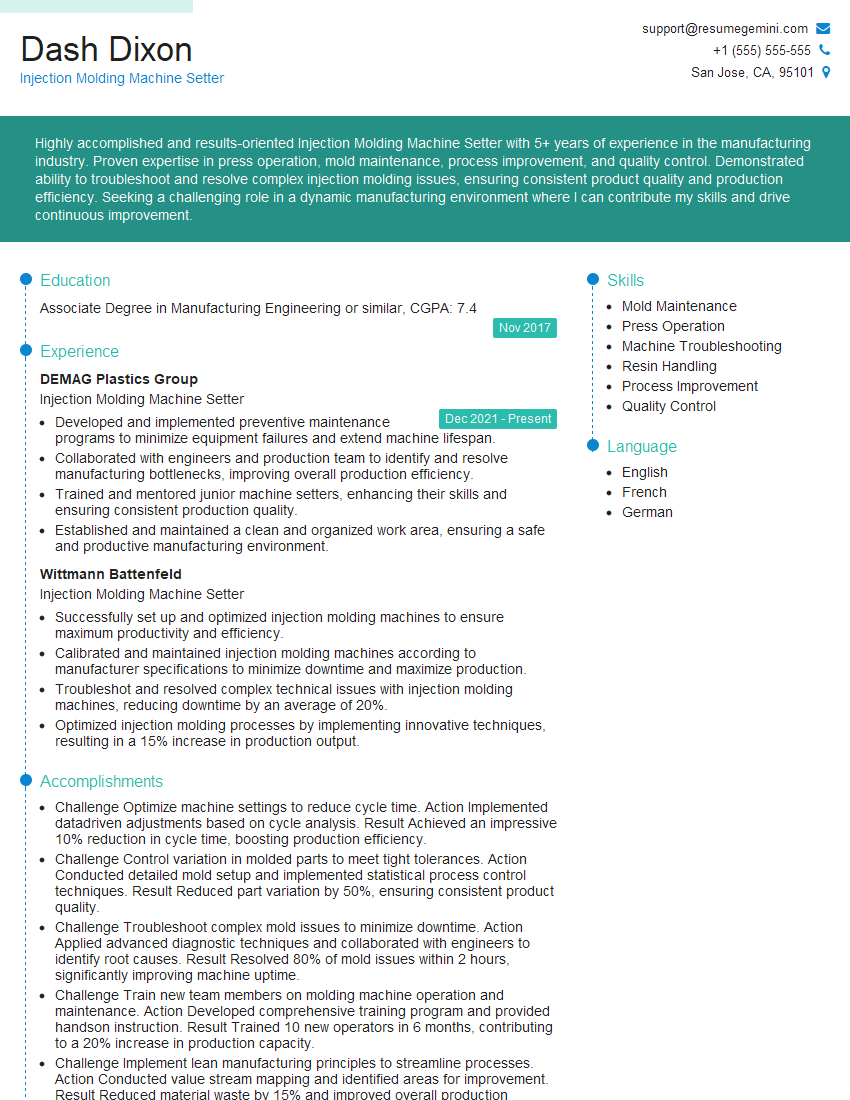

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Injection Molding Machine Setter

1. What are the key responsibilities of an Injection Molding Machine Setter?

As an Injection Molding Machine Setter, my primary responsibilities involve:

- Setting up and operating injection molding machines to produce plastic parts

- Monitoring production and making adjustments to ensure parts meet specifications

- Performing routine maintenance and troubleshooting to minimize downtime

- Maintaining a clean and safe work area

2. What types of plastic materials have you worked with?

I have experience working with a wide range of plastic materials, including:

- Polyethylene (PE)

- Polypropylene (PP)

- Polystyrene (PS)

- Acrylonitrile Butadiene Styrene (ABS)

- Polycarbonate (PC)

3. Describe the process of setting up an injection molding machine.

The process of setting up an injection molding machine typically involves:

- Installing the mold into the machine

- Adjusting the machine settings such as temperature, pressure, and cycle time

- Loading the plastic material into the hopper

- Starting the machine and monitoring production

4. What are some common problems that can occur during injection molding and how do you troubleshoot them?

Some common problems that can occur during injection molding include:

- Short shots: Caused by insufficient plastic material being injected into the mold. Can be resolved by increasing the injection pressure or material temperature.

- Flash: Caused by excess plastic material leaking out of the mold. Can be resolved by adjusting the mold clamping force or using a different mold design.

- Sink marks: Caused by the plastic material cooling too quickly. Can be resolved by increasing the material temperature or using a slower cooling cycle.

5. How do you ensure the quality of the plastic parts produced?

I follow a strict quality control process to ensure the quality of the plastic parts produced:

- Inspecting the parts for defects such as cracks, voids, or dimensional errors

- Using measuring tools such as calipers and micrometers to verify part dimensions

- Maintaining documentation on all quality control checks performed

6. What types of preventive maintenance tasks do you perform on injection molding machines?

I perform the following preventive maintenance tasks on injection molding machines:

- Lubricating moving parts

- Cleaning the machine and its components

- Checking and replacing filters

- Inspecting hoses and belts for wear

7. What is your experience with using computer-aided manufacturing (CAM) software to program injection molding machines?

I am proficient in using CAM software to create and edit programs for injection molding machines. This allows me to:

- Optimize machine settings and reduce setup time

- Quickly and accurately create new programs for different parts

- Troubleshoot problems by analyzing program data

8. What are the safety precautions you take when operating injection molding machines?

I prioritize safety by adhering to the following precautions:

- Wearing appropriate personal protective equipment (PPE), including safety glasses and gloves

- Never operating a machine unless I am trained and authorized

- Keeping my work area clean and free of obstructions

- Following lockout/tagout procedures when performing maintenance

9. How do you stay up-to-date on the latest advances in injection molding technology?

I actively seek opportunities to expand my knowledge and stay current with the latest advancements:

- Attending industry conferences and webinars

- Reading technical articles and journals

- Networking with other professionals in the field

- Seeking certifications or professional development courses

10. If I walk you over to an injection molding machine, what would you check first?

Firstly, I would:

- Ensure the machine is properly grounded and the safety guards are in place

- Inspect the mold for any signs of damage or wear

- Check the material hopper to ensure there is sufficient material

- Verify the machine settings, including temperature, pressure, and cycle time, against the production order

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Injection Molding Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Injection Molding Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Injection Molding Machine Setter is responsible for installing and operating injection molding machines, troubleshoot technical issues, and perform routine maintenance on the equipment.

1. Set Up and Operate Injection Molding Machines

Set up and operate injection molding machines according to specifications.

- Correctly install and set molds into the machine.

- Set up and adjust injection parameters, such as temperature, pressure, and cycle time.

- Monitor the machine’s operation and make necessary adjustments to ensure production efficiency and quality.

2. Troubleshoot Technical Issues

Troubleshooting technical issues that arise during the injection molding process.

- Identify and diagnose problems with the machine or mold, incorrect part dimensions, and other production issues.

- Take corrective actions to resolve problems, such as adjusting parameters, replacing worn parts, or calling for technical assistance.

- Document and report any significant issues or repairs.

3. Routine Maintenance

Perform routine maintenance on injection molding machines.

- Clean and lubricate machines.

- Inspect and replace worn or damaged parts.

- Perform preventive maintenance tasks to ensure optimal machine performance.

4. Quality Control

Inspect parts and verify dimensions to ensure they meet specifications.

- Use measuring instruments, such as calipers and micrometers, to check part dimensions.

- Identify and reject defective parts.

- Work with quality control personnel to implement and maintain quality standards.

Interview Tips

To ace an interview for an Injection Molding Machine Setter position, it’s important to prepare thoroughly and demonstrate your technical knowledge, problem-solving abilities, and attention to detail.

1. Research the Company and the Role

Before the interview, take the time to research the company and the specific role you are applying for. This will help you understand the company’s culture, products or services, and the specific challenges and responsibilities of the position.

- Visit the company’s website to learn about their history, values, and current projects.

- Read industry publications and news articles to stay up-to-date on the latest trends and technologies in injection molding.

- Network with people in the industry to gain insights into the company and the role.

2. Highlight Your Technical Skills

Emphasize your technical skills and experience with injection molding machines.

- Describe your experience in setting up, operating, and troubleshooting injection molding machines.

- Discuss your knowledge of injection molding parameters, such as temperature, pressure, and cycle time, and how you optimize them for different materials and products.

- Mention any certifications or training programs you have completed in injection molding.

3. Demonstrate Problem-Solving Abilities

Provide examples of how you have solved technical problems with injection molding machines.

- Describe a situation where you identified a problem with a machine and implemented a solution that improved its performance.

- Explain how you diagnosed and repaired a mold that was causing defective parts.

- Discuss your approach to troubleshooting and resolving production issues.

4. Show Attention to Detail

Injection Molding Machine Setters must have a strong attention to detail.

- Highlight your experience in inspecting parts for quality and accuracy.

- Describe your understanding of ISO 9001 or other quality standards.

- Explain how you ensure that parts meet customer specifications and industry standards.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Injection Molding Machine Setter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.