Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Injection Molding Machine Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Injection Molding Machine Tender so you can tailor your answers to impress potential employers.

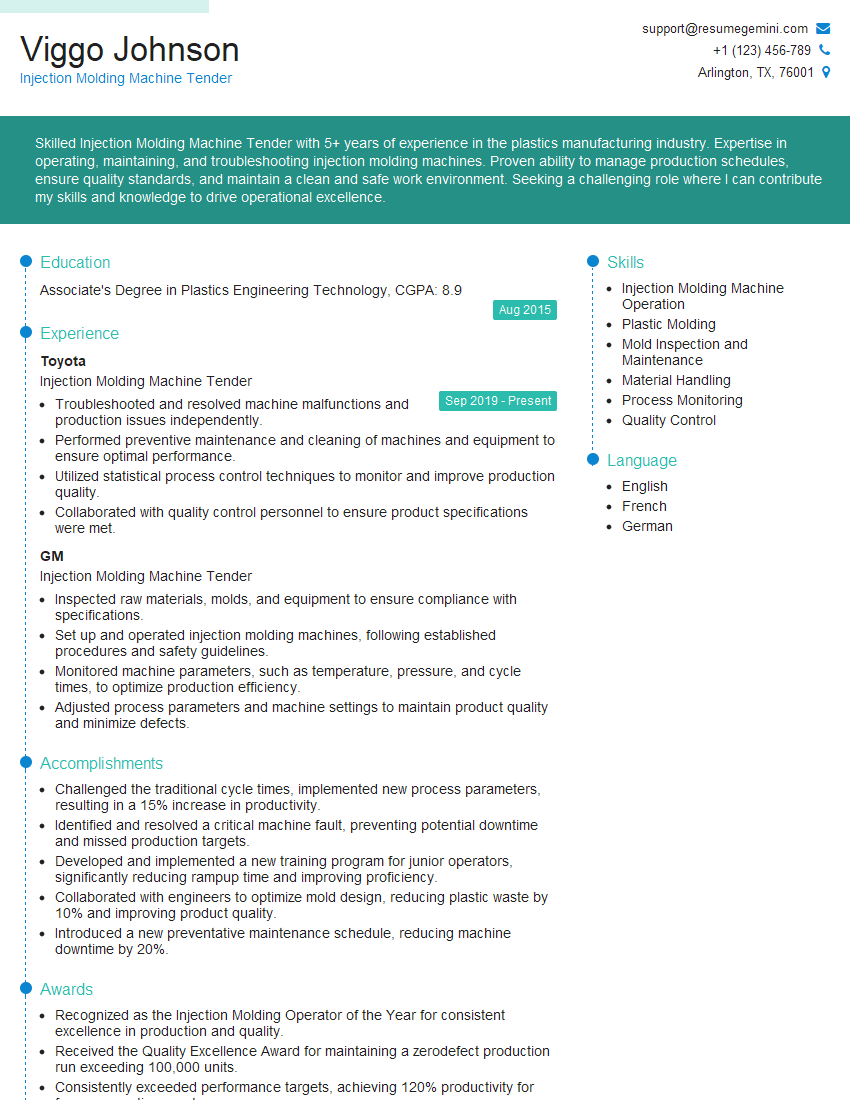

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Injection Molding Machine Tender

1. What are the key performance indicators (KPIs) that you track to measure the efficiency and effectiveness of your injection molding process?

To measure the efficiency and effectiveness of my injection molding process, I track the following KPIs:

- Cycle time: This is the total time it takes to produce a single part, from mold opening to mold closing.

- Defects per million (DPM): This is the number of defective parts produced per million parts produced.

- Overall equipment effectiveness (OEE): This is a measure of how effectively the injection molding machine is being used, taking into account factors such as downtime, scrap, and speed.

2. Describe the process of setting up an injection molding machine for a new product.

Material Preparation

- Inspect the material to ensure it meets the required specifications.

- Dry the material to remove any moisture that could cause defects.

Machine Setup

- Install the mold into the machine.

- Set the machine parameters, such as injection pressure, temperature, and cycle time.

- Calibrate the machine to ensure that it is producing parts to the correct specifications.

Production Run

- Start the production run and monitor the machine to ensure that it is running smoothly.

- Make adjustments to the machine parameters as needed to optimize the process.

- Inspect the parts to ensure that they meet the required specifications.

3. What are the common defects that can occur in injection molding, and what are the causes and solutions for each?

Here are some common defects that can occur in injection molding, along with their causes and solutions:

- Short shots: These occur when the mold is not completely filled with molten plastic. Causes include insufficient injection pressure, incorrect mold temperature, or material that is too cold. Solutions include increasing injection pressure, increasing mold temperature, or preheating the material.

- Flash: This is excess plastic that seeps out of the mold. Causes include incorrect mold clamping force, worn mold components, or excessive injection pressure. Solutions include increasing mold clamping force, replacing worn mold components, or reducing injection pressure.

- Sink marks: These are depressions in the part that occur when the plastic shrinks as it cools. Causes include incorrect cooling rate, insufficient material packing, or material with high shrinkage. Solutions include slowing the cooling rate, increasing material packing, or using a material with lower shrinkage.

4. How do you troubleshoot an injection molding machine that is not producing parts to the correct specifications?

To troubleshoot an injection molding machine that is not producing parts to the correct specifications, I would:

- Check the machine parameters to ensure that they are set correctly.

- Inspect the mold for any damage or wear.

- Check the material to ensure that it is the correct type and grade.

- Inspect the parts for any defects.

- Make adjustments to the machine parameters, mold, or material as needed to correct the problem.

5. What are the safety precautions that you take when operating an injection molding machine?

When operating an injection molding machine, I take the following safety precautions:

- Wear appropriate personal protective equipment, such as safety glasses, gloves, and a lab coat.

- Keep the work area clean and free of debris.

- Be aware of the location of the emergency stop button.

- Never reach into the mold while the machine is running.

- Follow all lockout/tagout procedures when performing maintenance on the machine.

6. What types of maintenance do you perform on an injection molding machine?

I perform the following types of maintenance on an injection molding machine:

- Daily maintenance: This includes tasks such as cleaning the machine, checking the oil levels, and inspecting the mold.

- Weekly maintenance: This includes tasks such as lubricating the machine, checking the belts and hoses, and calibrating the machine.

- Monthly maintenance: This includes tasks such as cleaning the cooling system, inspecting the electrical components, and replacing any worn parts.

- Annual maintenance: This includes tasks such as overhauling the machine, replacing major components, and performing a complete safety inspection.

7. How do you stay up-to-date on the latest injection molding technologies and best practices?

I stay up-to-date on the latest injection molding technologies and best practices by:

- Reading trade publications and attending industry conferences.

- Participating in online forums and discussion groups.

- Taking continuing education courses.

- Networking with other injection molding professionals.

8. What are the benefits of using automation in injection molding?

The benefits of using automation in injection molding include:

- Increased productivity: Automated machines can run faster and more consistently than manual machines, which can lead to increased production output.

- Reduced labor costs: Automated machines can eliminate the need for manual labor, which can save on labor costs.

- Improved quality: Automated machines can produce parts with greater precision and consistency than manual machines, which can lead to improved product quality.

- Reduced waste: Automated machines can help to reduce waste by reducing the number of defective parts produced.

9. What are the challenges of working as an injection molding machine tender?

The challenges of working as an injection molding machine tender include:

- The need for technical expertise: Injection molding machine tenders need to have a strong understanding of injection molding technology and be able to troubleshoot problems quickly.

- The potential for repetitive work: Injection molding machine tenders may be required to perform repetitive tasks for long periods of time.

- The potential for exposure to hazardous materials: Injection molding machine tenders may be exposed to hazardous materials, such as molten plastic and chemicals.

10. What are your career goals as an injection molding machine tender?

My career goals as an injection molding machine tender are to:

- Become a highly skilled and knowledgeable injection molding machine tender.

- Contribute to the success of my company by producing high-quality parts efficiently and effectively.

- Advance my career by taking on additional responsibilities and learning new skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Injection Molding Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Injection Molding Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Injection Molding Machine Tenders perform a crucial role in manufacturing processes, operating and maintaining injection molding machines to produce plastic parts. Their key job responsibilities include:

1. Machine Operation and Maintenance

Setting up, operating, and monitoring injection molding machines to produce plastic parts.

- Ensuring proper setup and operating conditions to optimize production efficiency.

- Performing routine maintenance, troubleshooting, and repairs on molding machines to minimize downtime.

2. Mold Management

Handling and installing molds into injection molding machines.

- Changing and replacing molds as required to produce different plastic parts.

- Inspecting molds for wear and damage, and reporting any issues to supervisors.

3. Quality Control

Ensuring the quality of injection-molded parts.

- Conducting visual inspections, measuring dimensions, and checking part properties.

- Identifying and correcting any defects or variations in parts, maintaining product quality standards.

4. Material Handling

Handling and preparing raw plastic materials.

- Loading and unloading plastic granules into molding machines.

- Ensuring appropriate storage and handling of plastic materials to prevent contamination.

Interview Tips

To ace the interview for an Injection Molding Machine Tender position, it’s crucial to prepare thoroughly. Here are some interview tips and hacks:

1. Research the Company and Industry

Familiarize yourself with the company’s background, products, and manufacturing processes. Understanding the industry’s trends and technological advancements will demonstrate your interest and knowledge.

2. Highlight Relevant Skills

Emphasize your technical skills in operating and maintaining injection molding machines. Quantify your experience with specific examples and metrics, showcasing your ability to optimize production and ensure quality.

3. Showcase Problem-Solving Abilities

Share instances where you’ve successfully identified and resolved issues with molding machines or quality problems. Your ability to troubleshoot and find solutions under pressure will be highly valued.

4. Prepare for Safety Questions

As safety is paramount in manufacturing, be prepared to answer questions about your knowledge of safety protocols, equipment safety features, and emergency procedures.

5. Ask Insightful Questions

Asking thoughtful questions during the interview shows your genuine interest and engagement. Prepare questions related to the company’s commitment to innovation, training opportunities, or sustainability practices.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Injection Molding Machine Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Injection Molding Machine Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.