Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Injection Molding Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

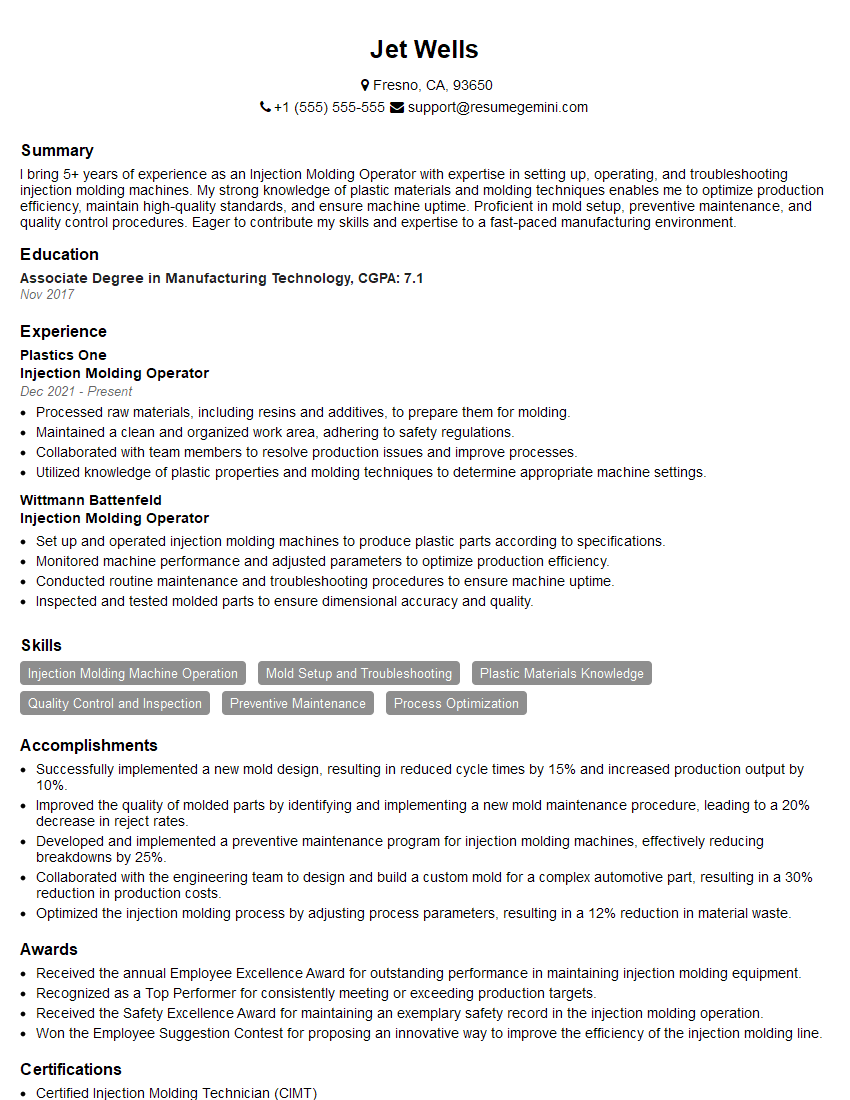

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Injection Molding Operator

1. What is the process of injection molding?

Injection molding is a manufacturing process used to produce plastic parts. The process begins by melting plastic pellets in a heated barrel. The molten plastic is then injected into a mold cavity, where it cools and solidifies into the desired shape.

2. What are the different types of injection molding machines?

Clamp Type

- Toggle Clamp

- Hydraulic Clamp

- Vertical Clamp

Injection Unit Type

- Reciprocating Screw

- Plunger

3. What are the different factors that affect the quality of an injection molded part?

- Mold design

- Material selection

- Process parameters

- Environmental conditions

4. What are the common defects that can occur in injection molded parts?

- Short shots

- Flash

- Warping

- Sink marks

5. How do you troubleshoot an injection molding machine?

- Identify the problem.

- Determine the cause of the problem.

- Correct the problem.

- Verify that the problem has been solved.

6. What are the safety precautions that must be taken when operating an injection molding machine?

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Do not operate the machine if you are not trained to do so.

- Follow all safety procedures outlined by the manufacturer.

7. What are the quality control procedures that are used to ensure the quality of injection molded parts?

- Visual inspection

- Dimensional measurement

- Material testing

- Functional testing

8. What are the different types of molds that are used in injection molding?

- Two-plate molds

- Three-plate molds

- Hot runner molds

- Cold runner molds

9. What are the different types of materials that can be used in injection molding?

- Thermoplastics

- Thermosets

- Elastomers

10. What are the advantages and disadvantages of injection molding?

Advantages

- High production rates

- Good dimensional accuracy

- Complex shapes can be produced

- Variety of materials can be used

Disadvantages

- High tooling costs

- Long lead times

- Limited part size

- Can be difficult to troubleshoot

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Injection Molding Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Injection Molding Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Injection Molding Operators are responsible for the smooth functioning of injection molding machines, ensuring high-quality production of plastic products. Key job responsibilities include:

1. Machine Operation and Monitoring

Setting up and operating injection molding machines, monitoring production processes, and making necessary adjustments to ensure smooth operation and product quality.

- Checking mold settings, temperature, cycle times, and feed rates

- Identifying and troubleshooting machine malfunctions

2. Quality Control and Inspection

Inspecting finished products for defects, checking dimensions, and ensuring that they meet specified quality standards.

- Performing visual inspections and measurements

- Maintaining quality control records and reporting any issues

3. Maintenance and Troubleshooting

Performing basic maintenance tasks such as cleaning, lubrication, and minor repairs to ensure machine uptime and prevent breakdowns.

- Performing preventive maintenance according to established schedules

- Troubleshooting and resolving machine problems

4. Material Handling

Loading and unloading plastic pellets or other raw materials into the injection molding machine, monitoring material flow, and maintaining inventory levels.

- Checking inventory and ordering materials as needed

- Safely handling hazardous materials

Interview Preparation Tips

To impress interviewers, candidates should prepare thoroughly for their Injection Molding Operator interview. Here are some tips:

1. Research the Company and Position

Learn about the company’s products, industry standing, and specific requirements for the Injection Molding Operator role. This knowledge will enable you to tailor your answers to the interviewer’s questions.

2. Practice Your Answers

Prepare concise and well-structured responses to common interview questions related to your skills, experience, and suitability for the role. Practice delivering your answers confidently and clearly.

3. Highlight Relevant Skills and Experience

Emphasize your proficiency in injection molding machine operation, quality control, maintenance, and troubleshooting. Quantify your accomplishments and provide specific examples whenever possible.

4. Demonstrate Safety Awareness

Injection molding processes can involve potential hazards. Highlight your understanding of safety protocols and adherence to industry standards. Showcase your commitment to maintaining a safe work environment.

5. Be Enthusiastic and Professional

Convey your enthusiasm for the Injection Molding Operator role and the industry. Maintain a professional demeanor throughout the interview, dress appropriately, and arrive on time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Injection Molding Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.