Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Injection Molding Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

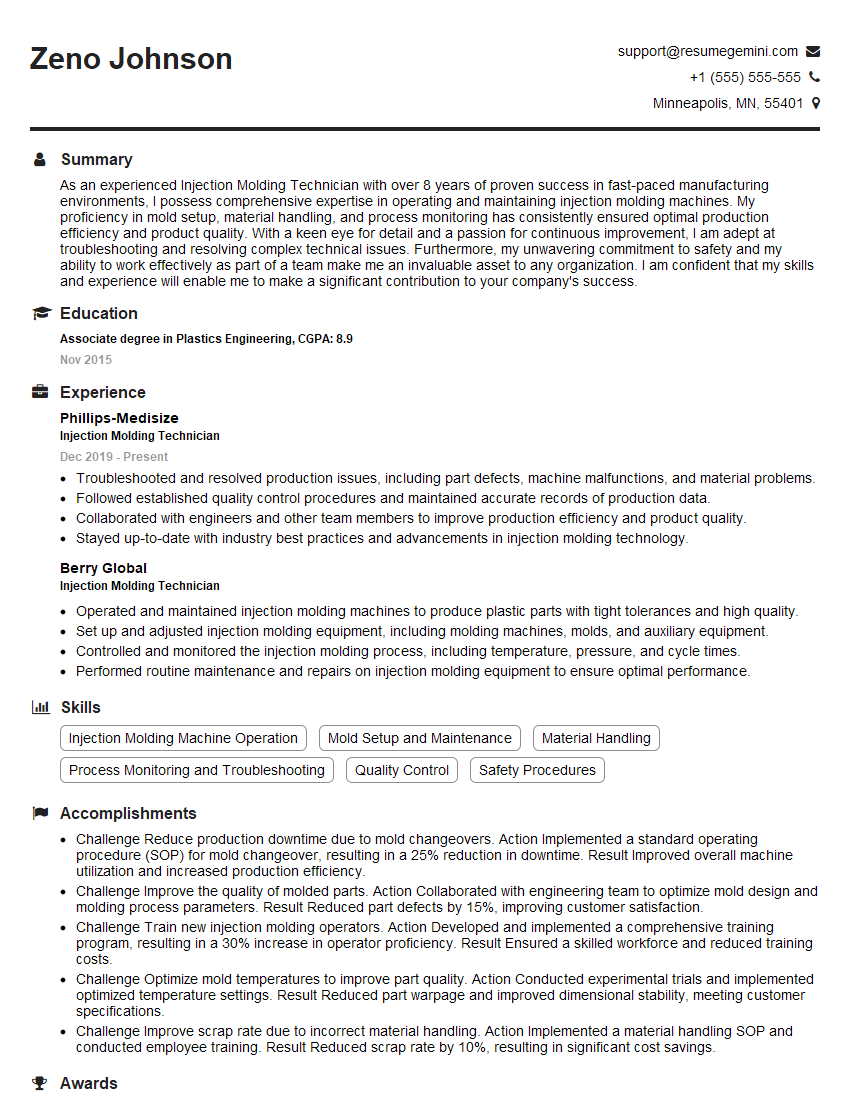

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Injection Molding Technician

1. Describe the process of injection molding?

Injection molding is a manufacturing process that involves injecting molten plastic material into a mold cavity to create a desired shape. The process generally involves the following steps:

- Clamping: The mold halves are closed and clamped together to form the mold cavity.

- Injection: Molten plastic is injected into the mold cavity under high pressure.

- Cooling: The mold is cooled to solidify the plastic.

- Ejection: The mold opens, and the finished part is ejected.

2. What are the different types of injection molding machines?

Hydraulic machines:

- Use hydraulic pressure to power the injection unit and mold clamping system.

- Provide precise control and high clamping force.

Electric machines:

- Use electric motors to power the injection unit and mold clamping system.

- Offer energy efficiency, reduced noise, and improved precision.

3. What are the key factors to consider when setting up an injection molding machine?

The key factors to consider when setting up an injection molding machine include:

- Material properties: Different plastic materials have different flow characteristics and require specific molding parameters.

- Mold design: The mold cavity dimensions and gate design affect the flow of plastic and the quality of the finished part.

- Process parameters: Injection pressure, mold temperature, and cooling time impact the properties of the molded part.

- Machine capabilities: The size and capabilities of the injection molding machine must match the requirements of the mold and the desired production rate.

4. What are the common defects that can occur in injection molding?

Common defects in injection molding include:

- Short shots: Incomplete filling of the mold cavity due to insufficient injection pressure or material.

- Flash: Excess plastic material that escapes from the mold parting line.

- Voids: Air pockets or gaps in the molded part due to improper venting or material shrinkage.

- Weld lines: Visible lines that indicate the merging of separate plastic flows within the part.

- Warpage: Distortion of the molded part due to uneven cooling or material shrinkage.

5. How do you troubleshoot common injection molding defects?

Troubleshooting common injection molding defects involves:

- Identifying the defect: Observe the molded part and determine the type of defect.

- Analyzing the process: Review the injection molding parameters, mold design, and material properties.

- Making adjustments: Adjust process parameters, modify the mold, or change the material as necessary.

- Testing and verifying: Run test shots to verify the effectiveness of the troubleshooting measures.

6. What maintenance tasks are essential for injection molding machines?

Essential maintenance tasks for injection molding machines include:

- Regular cleaning: Remove plastic residue, debris, and contaminants from the machine and mold.

- Lubrication: Lubricate moving parts to reduce wear and tear.

- Inspection: Check for wear, damage, or leaks in the machine and mold.

- Preventive maintenance: Perform scheduled maintenance tasks to prevent breakdowns and extend machine life.

7. What safety precautions should be taken when operating injection molding machines?

Important safety precautions for injection molding machines include:

- Wear appropriate safety gear: Protective clothing, safety glasses, and gloves.

- Follow machine safety protocols: Observe lock-out/tag-out procedures and maintain a safe distance from moving parts.

- Be aware of potential hazards: Hot plastic, sharp edges, and high-pressure injection can pose risks.

- Stay alert and focused: Pay attention to the machine operation and avoid distractions.

8. What is the role of quality control in injection molding?

Quality control in injection molding involves:

- Establishing quality standards: Defining acceptable limits for part dimensions, appearance, and properties.

- Inspection and testing: Performing visual inspections, dimensional measurements, and functional tests to ensure parts meet specifications.

- Corrective actions: Identifying and implementing measures to resolve quality issues and improve processes.

- Process monitoring: Tracking process parameters and part quality to identify areas for improvement and prevent defects.

9. What are some emerging trends in injection molding technology?

Emerging trends in injection molding technology include:

- Industry 4.0 integration: Connecting machines to IoT systems for data collection, process optimization, and remote monitoring.

- Additive manufacturing integration: Combining injection molding with 3D printing to create complex parts and prototypes.

- Sustainable practices: Using biodegradable materials, reducing energy consumption, and implementing waste reduction measures.

- Advanced materials: Development of new plastic materials with enhanced properties, such as heat resistance and chemical resistance.

10. How do you stay updated on the latest developments in injection molding?

To stay updated on the latest developments in injection molding, I engage in the following:

- Attend industry conferences and trade shows: Learn about new technologies, materials, and best practices.

- Read industry publications and technical journals: Stay informed about research and advancements in the field.

- Participate in online forums and discussion groups: Connect with other professionals and exchange knowledge.

- Collaborate with suppliers and manufacturers: Get insights into emerging technologies and industry trends.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Injection Molding Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Injection Molding Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Injection Molding Technicians are integral members of manufacturing teams, responsible for operating and maintaining injection molding machines, ensuring efficient and high-quality production.

1. Machine Operation and Maintenance

Skilled in setting up, operating, and monitoring injection molding machines, ensuring proper functioning, output, and adherence to quality standards.

- Adjusting machine settings for different products.

- Performing regular maintenance, cleaning, lubrication, and troubleshooting.

2. Mold Preparation and Management

Manage and maintain injection molding tools (molds), ensuring correct installation, cleaning, and appropriate storage.

- Analyzing molds for defects or wear, and recommending repairs if necessary.

- Working closely with engineers to troubleshoot and resolve molding issues.

3. Material Handling and Process Control

Handle and manage raw materials, ensuring proper storage and preparation for injection molding.

- Monitoring process parameters (e.g., temperature, pressure, cycle times) to optimize production efficiency.

- Performing quality control checks on finished products to ensure compliance with specifications.

4. Equipment and Safety Compliance

Ensure a safe and efficient work environment by following proper safety protocols and adhering to equipment maintenance schedules.

- Reporting any potential hazards or equipment malfunctions promptly.

- Working in accordance with industry regulations and best practices.

Interview Tips

Preparing thoroughly for an Injection Molding Technician interview is essential for a successful outcome. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and industry standing.

- Review the job description thoroughly, identifying key responsibilities and qualifications.

- Anticipate potential interview questions and prepare thoughtful answers that highlight your relevant skills.

2. Highlight Relevant Skills and Experience

Quantify your accomplishments and provide specific examples of your injection molding expertise.

- Discuss your experience with specific types of molding machines and molds.

- Emphasize your ability to troubleshoot and resolve production issues.

3. Demonstrate Safety and Quality Consciousness

Injection molding involves safety protocols and quality control measures.

- Showcase your knowledge of industry safety regulations and your commitment to a safe work environment.

- Highlight your understanding of quality control processes and your ability to ensure product quality.

4. Prepare Questions for the Interviewers

Asking thoughtful questions demonstrates your interest and engagement in the position.

- Inquire about opportunities for professional growth and advancement.

- Ask about the company’s approach to quality control and safety.

5. Professionalism and Etiquette

Dress appropriately and arrive on time for the interview.

- Maintain eye contact and actively engage with the interviewers.

- Be respectful and professional throughout the interview process.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Injection Molding Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Injection Molding Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.