Are you gearing up for an interview for a Ink Blender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Ink Blender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

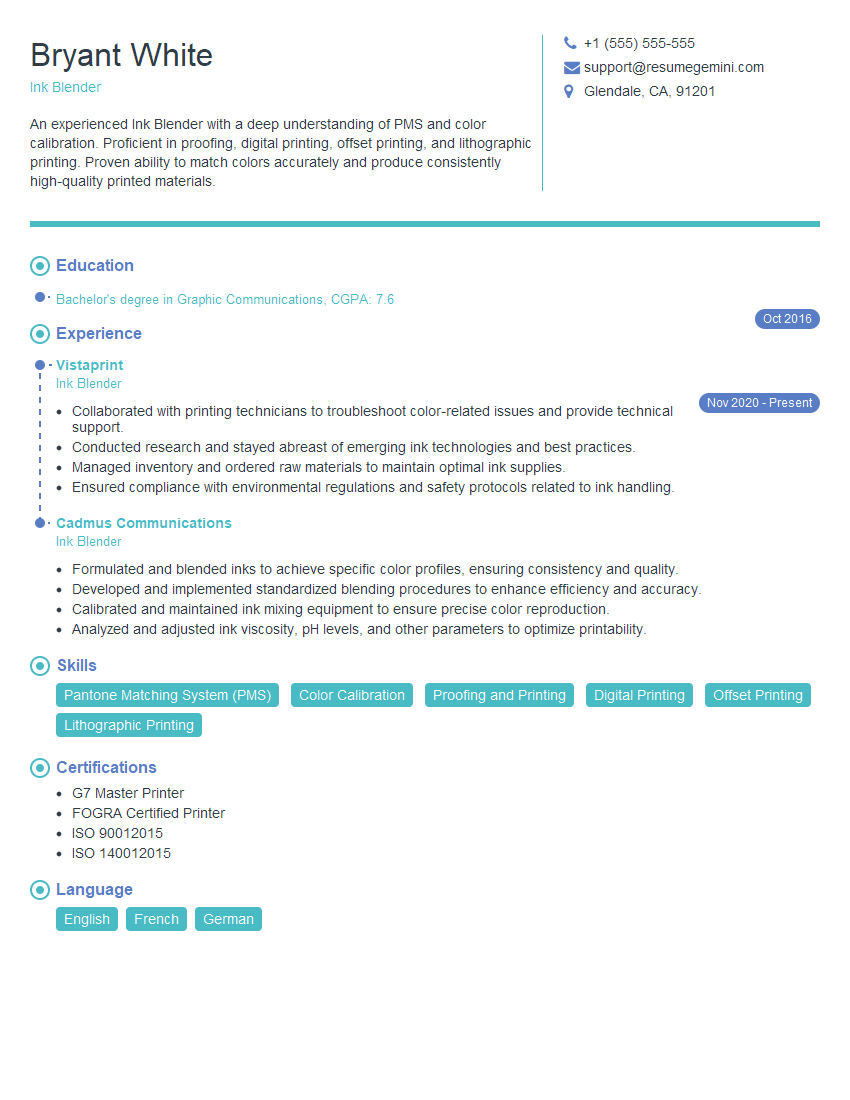

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ink Blender

1. How do you ensure that the ink you blend meets the required specifications?

I ensure the ink meets the required specifications by following a rigorous quality control process. This process includes:

- Testing the ink viscosity, pH, and color.

- Comparing the test results to the specifications.

- Making adjustments to the ink as needed to meet the specifications.

2. What is the difference between offset printing ink and flexographic printing ink?

Composition

- Offset printing ink is composed of pigments, resins, and solvents.

- Flexographic printing ink is composed of pigments, resins, and water.

Viscosity

- Offset printing ink has a higher viscosity than flexographic printing ink.

- This means that offset printing ink is thicker and more difficult to flow.

Drying time

- Offset printing ink dries more slowly than flexographic printing ink.

- This means that offset printing ink is more likely to smudge or smear.

3. What are the challenges of blending ink for digital printing?

The challenges of blending ink for digital printing include:

- Color accuracy: Digital printing requires precise color accuracy to produce high-quality prints.

- Inkjet compatibility: The ink must be compatible with the inkjet printer being used to ensure proper print quality.

- Viscosity: The ink must have the correct viscosity to flow properly through the inkjet printer.

4. What is the purpose of using a spectrophotometer in ink blending?

A spectrophotometer is used in ink blending to measure the color of the ink. This information is used to ensure that the ink meets the required color specifications and to make adjustments to the ink as needed.

5. What are the different types of ink additives and what are their functions?

Types of ink additives

- Driers: Accelerate the drying process of the ink.

- Anti-foaming agents: Prevent the formation of foam in the ink.

- Wax: Controls the viscosity and flow of the ink.

- Slip agents: Improve the printability of the ink.

Functions of ink additives

- Improve the performance of the ink.

- Make the ink more compatible with the printing process.

- Control the appearance of the printed product.

6. What are the safety precautions that should be taken when blending ink?

The safety precautions that should be taken when blending ink include:

- Wear appropriate personal protective equipment (PPE). This includes gloves, safety glasses, and a respirator.

- Work in a well-ventilated area.

- Do not smoke or eat in the work area.

- Follow all manufacturer’s instructions for the ink and the blending equipment.

7. What is the difference between transparent and opaque ink?

- Transparent ink: Allows light to pass through it.

- Opaque ink: Blocks light from passing through it.

Transparent ink is used for printing on transparent or translucent materials, such as glass or plastic. Opaque ink is used for printing on opaque materials, such as paper or cardboard.

8. What are the different types of ink drying systems?

- Heatset: Uses heat to dry the ink.

- Coldset: Uses evaporation to dry the ink.

- UV curing: Uses ultraviolet light to dry the ink.

- Electron beam curing: Uses an electron beam to dry the ink.

The type of drying system used depends on the type of ink and the printing process.

9. What are the environmental regulations that apply to ink blending?

The environmental regulations that apply to ink blending include:

- The Clean Air Act: Regulates air emissions from ink blending operations.

- The Clean Water Act: Regulates water discharges from ink blending operations.

- The Resource Conservation and Recovery Act (RCRA): Regulates the disposal of hazardous waste from ink blending operations.

Ink blenders must comply with all applicable environmental regulations.

10. What are the future trends in ink blending?

The future trends in ink blending include:

- The development of new ink technologies: New ink technologies are being developed to improve the performance and environmental friendliness of inks.

- The increasing use of digital printing: Digital printing is becoming more popular, and this is driving the demand for inks that are compatible with digital printing processes.

- The growing emphasis on sustainability: There is a growing emphasis on sustainability in the printing industry, and this is driving the demand for inks that are environmentally friendly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ink Blender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ink Blender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Ink Blender plays a crucial role in the pre-press process, ensuring color consistency and accuracy in printed materials. Their key responsibilities include:

1. Ink Formulation and Mixing

Determine the appropriate ink formulation based on customer specifications and printing requirements.

- Calculate and weigh precise amounts of pigments, solvents, and additives.

- Mix inks thoroughly using a specialized blender to achieve uniform consistency.

2. Ink Testing and Quality Control

Conduct thorough testing to ensure that the blended inks meet quality standards.

- Use spectrophotometers and other instruments to measure color accuracy, density, and viscosity.

- Analyze test results and adjust ink formulations as needed to optimize performance.

3. Color Matching and Proofing

Match colors precisely based on customer specifications or provided samples.

- Create color proofs using blended inks and compare them to original artwork or digital files.

- Make necessary adjustments to achieve accurate color reproduction.

4. Collaboration and Communication

Collaborate with other departments, such as design and production, to ensure accurate ink specifications and timely delivery.

- Communicate ink properties, limitations, and handling instructions to relevant personnel.

- Provide technical support and troubleshoot color-related issues.

Interview Tips

To ace an interview for the Ink Blender position, it’s essential to prepare thoroughly and showcase your knowledge and skills.

1. Research the Company and Industry

Demonstrate your understanding of the company’s business and the printing industry. Research their latest projects, innovations, and market trends.

- Visit the company website and social media pages.

- Read industry publications and attend relevant webinars.

2. Highlight Your Technical Expertise

Emphasize your proficiency in ink formulation, testing, and color matching. Provide specific examples of your work and quantify your achievements.

- Discuss your experience with different types of inks and printing processes.

- Describe how you use analytical instruments to ensure accurate ink performance.

3. Showcase Your Problem-Solving Abilities

Hiring managers value candidates who can solve problems effectively. Share examples of how you have resolved color-related issues or improved ink quality.

- Present a situation where you identified and corrected a color discrepancy.

- Explain how you analyzed test results and made adjustments to optimize ink performance.

4. Practice Your Communication Skills

Ink Blenders must be able to communicate effectively with colleagues, customers, and suppliers. Prepare to answer questions about your ability to collaborate and provide technical support.

- Discuss your experience working in a team environment.

- Give examples of how you have communicated complex color-related information clearly.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ink Blender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!