Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Insert Molding Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Insert Molding Operator so you can tailor your answers to impress potential employers.

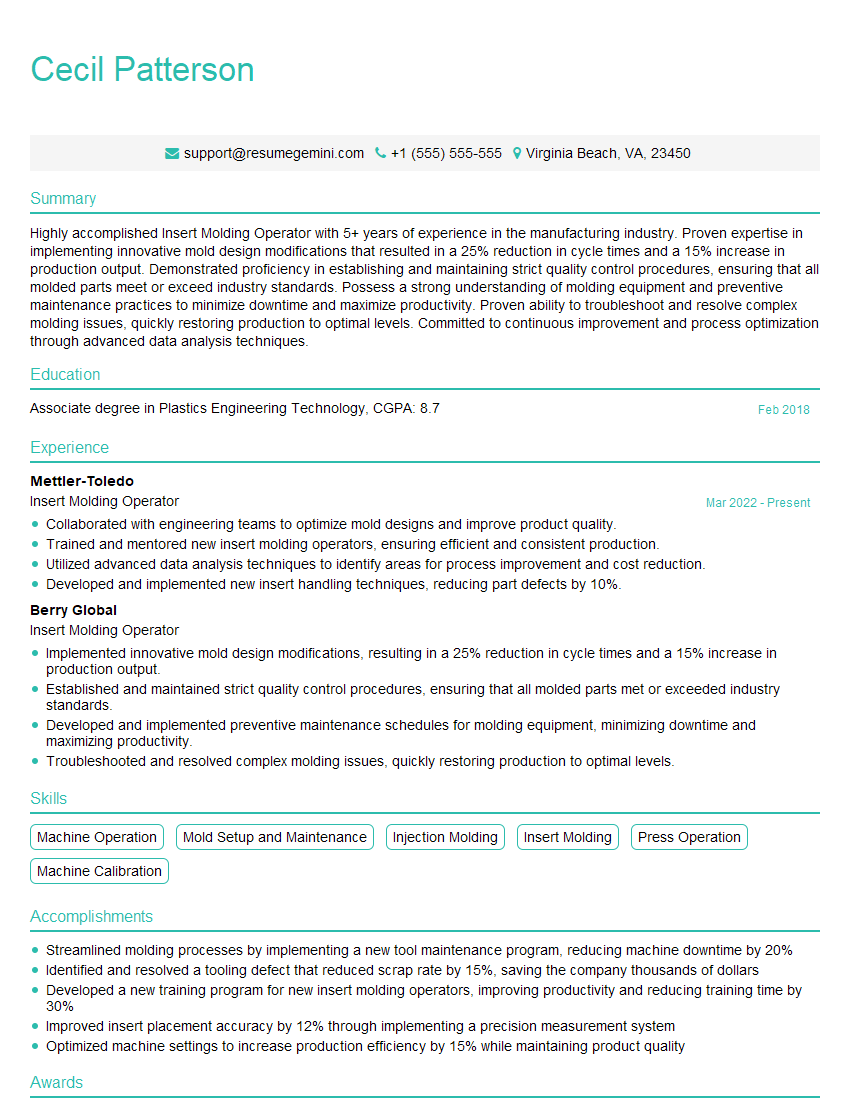

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Insert Molding Operator

1. What are the key steps involved in operating an insert molding machine?

- Properly align and secure the mold halves

- Measure and mix the resin and catalyst

- Inject the resin into the mold

- Insert the inserts into the mold

- Cure the resin

- Eject the finished part from the mold

2. What are the different types of inserts used in insert molding?

- Metal inserts

- Plastic inserts

- Ceramic inserts

- Electronic inserts

3. What are some of the common problems that can occur during insert molding?

- Defects in the resin

- Misalignment of the inserts

- Insufficient curing of the resin

- Damage to the mold

4. How do you troubleshoot problems with an insert molding machine?

- Check the machine for any visible damage

- Inspect the mold for any defects

- Check the resin and catalyst for any contamination

- Calibrate the machine according to the manufacturer’s instructions

5. What are some of the safety precautions that must be followed when operating an insert molding machine?

- Always wear appropriate safety gear

- Keep the work area clean and free of debris

- Never operate the machine when it is not properly guarded

- Be aware of the potential hazards of the materials being used

6. What is the difference between insert molding and overmolding?

- Insert molding involves inserting inserts into a mold before the plastic is injected

- Overmolding involves molding plastic around an existing part

7. What are the advantages of using insert molding?

- Increased strength and durability

- Improved electrical conductivity

- Reduced weight

- Enhanced aesthetics

8. What are the disadvantages of using insert molding?

- Increased complexity and cost

- Potential for defects

- Longer cycle times

9. What are the different types of insert molding presses?

- Vertical insert molding presses

- Horizontal insert molding presses

- Rotary insert molding presses

10. What is the future of insert molding?

- Continued growth in the use of insert molding

- Development of new and innovative insert molding technologies

- Increased use of insert molding in a variety of industries

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Insert Molding Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Insert Molding Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Insert Molding Operators play a crucial role in manufacturing processes, ensuring the production of high-quality, precision parts. Their primary responsibilities encompass:

1. Machine Operation and Maintenance

Skilled in operating and maintaining insert molding machines, including setup, monitoring, and troubleshooting.

- Setting up machines with proper molds and inserts.

- Monitoring machine performance, adjusting settings, and identifying potential issues.

- Performing routine maintenance tasks to ensure optimal machine functionality.

2. Molding Process Execution

Executing molding processes according to established specifications, adhering to quality standards.

- Loading molds with raw materials and inserts.

- Controlling temperature, pressure, and cycle times.

- Inspecting molded parts for defects and quality compliance.

3. Quality Control and Improvement

Monitoring and maintaining product quality, implementing continuous improvement measures.

- Conducting in-process inspections and final quality checks.

- Identifying areas for process optimization and suggesting improvements.

- Documenting quality records and maintaining production logs.

4. Safety and Maintenance

Upholding safety protocols and maintaining a clean and organized work environment.

- Following established safety procedures and wearing appropriate protective gear.

- Maintaining a clean and organized work area to prevent contamination and accidents.

- Reporting any safety hazards or potential risks.

Interview Tips

To excel in an Insert Molding Operator interview, it’s imperative to prepare thoroughly. Here are some valuable tips:

1. Research the Company and Industry

Familiarize yourself with the company’s background, products, and industry trends. This demonstrates your genuine interest and eagerness to contribute.

- Visit the company website, read industry publications, and attend relevant webinars.

- Highlight your knowledge of the latest industry advancements and how you can contribute to the company’s success.

2. Practice and Quantify Your Skills

Emphasize your technical skills and experience in insert molding operations. Quantify your accomplishments with specific examples and metrics.

- Describe your experience in setting up, operating, and maintaining insert molding machines.

- Share examples of how you implemented process improvements that led to increased productivity or reduced defects.

3. Showcase Your Quality-Driven Mindset

Highlight your commitment to quality and your understanding of quality control processes. Explain how you ensure that molded parts meet specifications and industry standards.

- Explain your knowledge of quality management systems, such as ISO 9001.

- Describe your experience in conducting inspections, identifying defects, and implementing corrective actions.

4. Emphasize Safety and Maintenance

Demonstrate your understanding of safety protocols and your ability to maintain a clean and organized work environment.

- Explain your knowledge of relevant safety regulations and how you ensure compliance.

- Describe your experience in maintaining equipment, identifying potential hazards, and implementing preventive maintenance measures.

5. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview shows your engagement and interest. Prepare questions that demonstrate your curiosity and desire to learn more about the role and the company.

- Ask about the company’s growth plans and how your skills can contribute to those plans.

- Inquire about opportunities for training and professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Insert Molding Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!