Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Inset Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

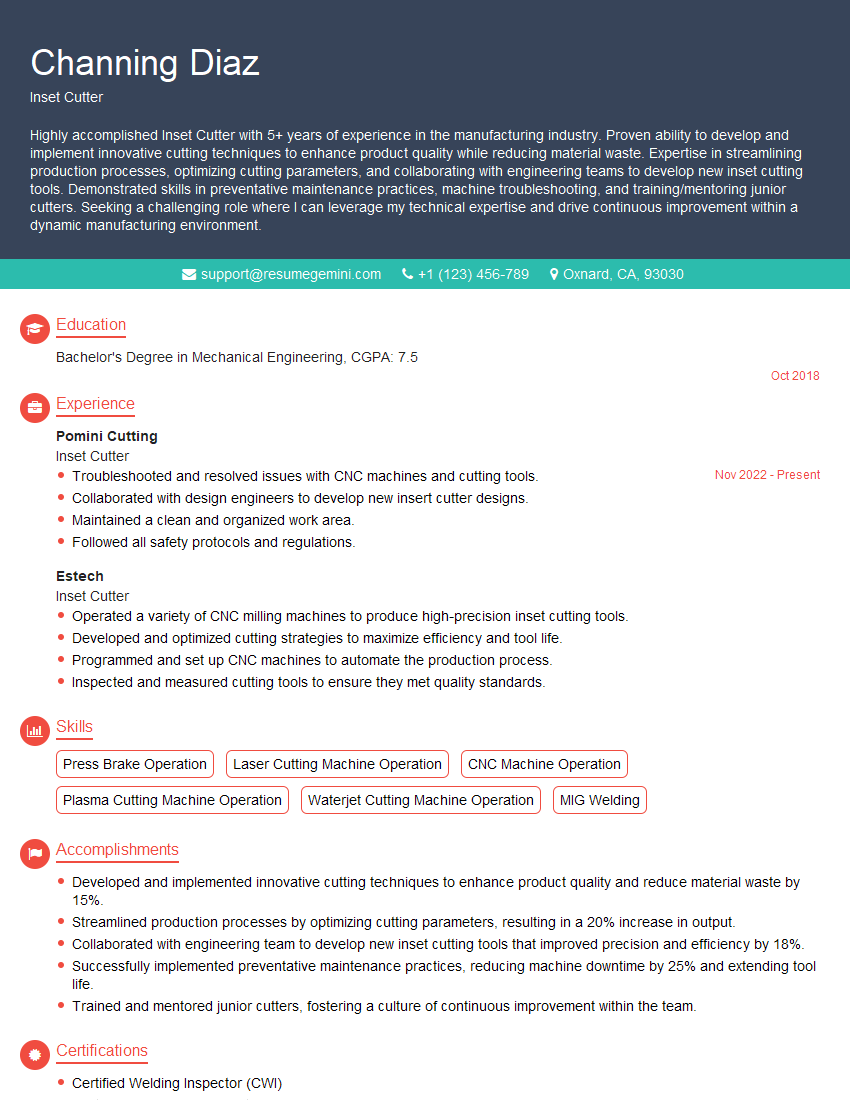

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Inset Cutter

1. How do you determine the correct cutting parameters (speed, feed, and depth of cut) for a given material and insert cutter combination?

To determine the correct cutting parameters, I would consider the following factors:

- Material properties (hardness, tensile strength, toughness)

- Insert cutter geometry (number of flutes, flute shape, rake angle)

- Machine capabilities (spindle speed, feed rate, power)

- Desired surface finish and accuracy

I would refer to manufacturer recommendations and cutting data charts to find a suitable starting point. Then, I would adjust the parameters based on the actual machining conditions and observe the performance of the insert cutter.

2. What are the different types of insert cutters available, and when would you use each type?

Positive rake cutters

- Sharp cutting edge, reducing cutting forces

- Suitable for soft materials (aluminum, copper)

- Produce good surface finish

Negative rake cutters

- Stronger cutting edge, allowing for higher feed rates

- Suitable for hard materials (steel, cast iron)

- Can produce burrs on the workpiece

Neutral rake cutters

- Compromise between positive and negative rake cutters

- Suitable for a wide range of materials and applications

3. How do you troubleshoot insert cutter failure?

To troubleshoot insert cutter failure, I would follow these steps:

- Inspect the insert cutter for chipping, wear, or breakage

- Check the cutting parameters (speed, feed, depth of cut) to ensure they are within the recommended range

- Inspect the workpiece for any defects or variations that may be causing the cutter to fail

- Verify that the insert cutter is properly mounted and secured in the tool holder

- Consider using a different insert cutter geometry or material

4. What are the safety precautions to observe when using insert cutters?

- Wear appropriate personal protective equipment (safety glasses, gloves, earplugs)

- Ensure that the machine is properly guarded to prevent contact with rotating parts

- Use the correct insert cutter for the specific application and material

- Follow recommended cutting parameters and avoid excessive force

- Inspect insert cutters regularly for wear or damage and replace them when necessary

5. How do you maintain insert cutters to ensure optimal performance?

- Clean insert cutters after each use to remove chips and debris

- Inspect insert cutters for wear or damage and replace them when necessary

- Lubricate insert cutters with cutting fluid to reduce friction and heat

- Store insert cutters in a dry and protected environment to prevent corrosion

- Follow manufacturer recommendations for resharpening or reconditioning insert cutters

6. What are the advantages and disadvantages of using insert cutters compared to solid cutters?

Advantages of insert cutters:

- Lower cost per cutting edge

- Easy to replace inserts, reducing downtime

- Versatile, allowing for a variety of cutting operations

Disadvantages of insert cutters:

- Lower rigidity than solid cutters

- May require more frequent insert replacement

- Can be more difficult to set up and adjust

7. How do you select the correct insert grade for a given application?

- Consider the material being machined (hardness, toughness, abrasiveness)

- Determine the cutting conditions (speed, feed, depth of cut)

- Refer to manufacturer recommendations and cutting data charts

- Experiment with different insert grades to find the optimal balance of wear resistance and cutting performance

8. What is the difference between roughing and finishing insert cutters?

- Roughing insert cutters have a larger chip load and are designed for removing large amounts of material quickly

- Finishing insert cutters have a smaller chip load and are designed for creating a smooth surface finish

9. How do you calculate the feed rate for an insert cutter?

The feed rate can be calculated using the following formula:

Feed rate = Cutting speed / Number of flutes x Number of teeth

- Cutting speed is usually expressed in meters per minute (m/min)

- Number of flutes is the number of cutting edges on the insert cutter

- Number of teeth is the number of teeth on the workpiece

10. What are the common problems that can occur when using insert cutters?

- Insert breakage due to excessive force or improper clamping

- Chipping or wear of the insert due to abrasive materials or high cutting temperatures

- Vibration due to unbalanced insert or improper tool holder

- Poor surface finish due to dull or damaged insert

- Insert pull-out due to insufficient clamping force

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Inset Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Inset Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Cutting and Shaping Metal Parts

Operate and maintain inset cutters, shapers, and other specialized machinery to cut and shape metal parts to precise specifications.

2. Reading Blueprints and Technical Drawings

Decipher blueprints, technical drawings, and work orders to determine cutting dimensions, angles, and material properties.

3. Inspecting Cut Parts

Examine cut parts to ensure they meet quality standards, dimensional accuracy, surface finish, and tolerance requirements.

4. Tooling and Equipment Setup

Select and install appropriate cutting tools, inserts, and fixtures to optimize cutting performance and ensure accuracy.

5. Machine Maintenance

Perform routine maintenance and repairs on inset cutters and related equipment to maintain optimal functionality.

6. Production Monitoring and Quality Control

Monitor production processes, ensure adherence to quality standards, and identify areas for improvement.

7. Collaborating with Engineers and Production Team

Consult with engineers and production team to discuss design specifications, material properties, and production timelines.

Interview Tips

Preparing for an interview for an Inset Cutter position requires proper research, practice, and understanding of the role’s responsibilities. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s mission, values, and industry standing. Research the specific position to gain insights into the job duties and expectations.

2. Practice Common Interview Questions

Anticipate potential interview questions related to your skills, experience, and knowledge of inset cutting techniques. Practice answering them concisely and highlighting your relevant qualifications.

3. Showcase Your Technical Expertise

Demonstrate your proficiency in operating inset cutters, interpreting technical drawings, and inspecting cut parts. Explain how you ensure precision and quality in your work.

4. Emphasize Problem-Solving and Critical Thinking

Highlight your ability to identify and resolve issues related to cutting processes, tooling setup, and machine maintenance. Describe how you approach problem-solving and improve efficiency.

5. Communicate Effectively

Articulate your ideas and technical concepts clearly, using industry-specific terminology. Show that you can effectively communicate with engineers, production teams, and supervisors.

6. Prepare Questions to Ask the Interviewer

Preparing thoughtful questions to ask the interviewer demonstrates your interest in the position and the company. It also provides an opportunity to clarify expectations and responsibilities.

Next Step:

Now that you’re armed with the knowledge of Inset Cutter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Inset Cutter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini