Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Inside Barrel Lathe Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

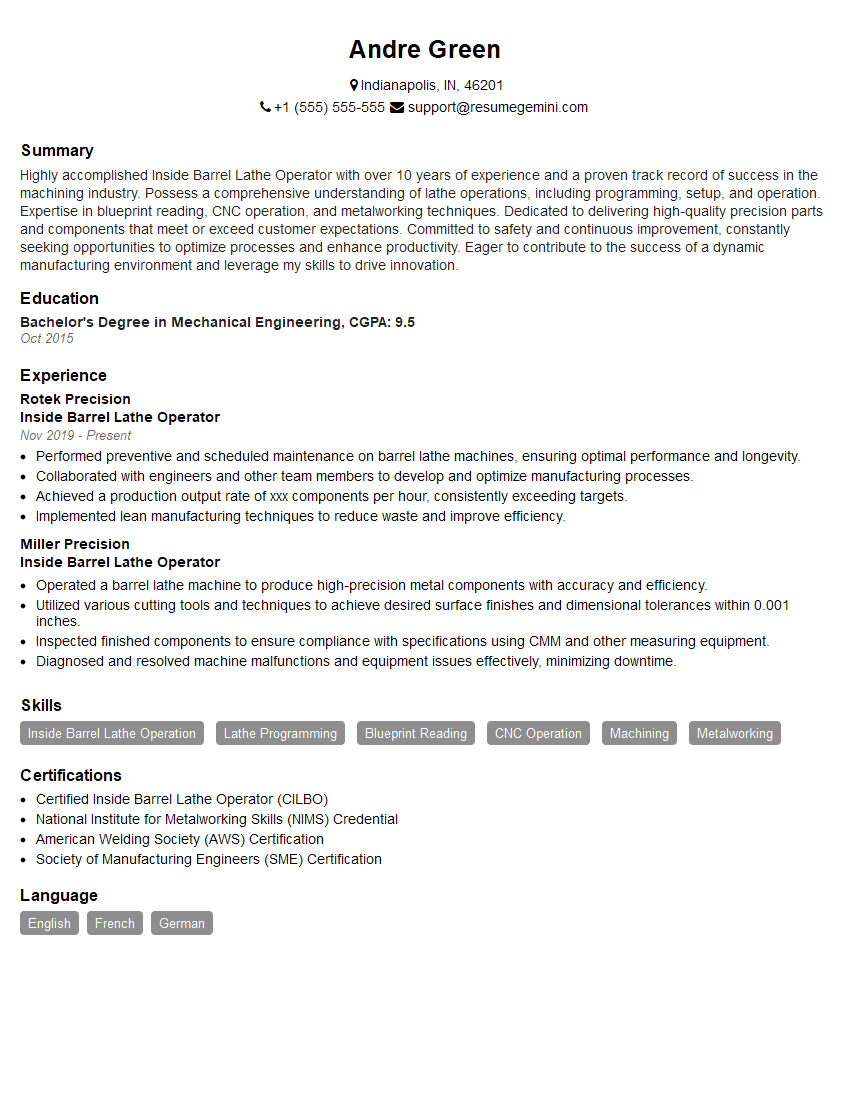

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Inside Barrel Lathe Operator

1. What are the key responsibilities of an Inside Barrel Lathe Operator?

As an Inside Barrel Lathe Operator, my primary responsibilities involve operating and maintaining a barrel lathe to produce barrels or other cylindrical parts within specified tolerances:

- Mount and secure workpieces on the lathe spindle, ensuring proper alignment and balance.

- Set up and adjust machine parameters, including cutting speed, feed rate, and tool depth, based on workpiece specifications and materials.

2. What are the different types of cutting tools used in Inside Barrel Lathe operations?

Boring Tools:

- Single-point tools, inserted blade tools, and boring bars

- Used for creating cylindrical bores or enlarging existing bores

Facing Tools:

- Square or round insert tooling

- Used for creating flat surfaces perpendicular to the lathe axis

3. Can you describe the process of machining a barrel on an Inside Barrel Lathe?

Machining a barrel on an Inside Barrel Lathe involves several steps:

- Rough Boring: Using a boring tool, the initial bore is created to the approximate size and shape.

- Finish Boring: The bore is brought to its final dimensions and surface finish using a smaller boring tool.

- Facing: The ends of the barrel are faced to create flat surfaces perpendicular to the bore.

- Contouring: If required, specific contours or profiles can be machined into the barrel using appropriate cutting tools.

4. How do you ensure the accuracy and quality of machined barrels?

Accuracy and quality are crucial in barrel machining. I employ several measures to achieve this:

- Precise Machine Setup: Calibrating the lathe and ensuring proper alignment of tools and workpieces minimizes errors.

- Accurate Tool Selection: Selecting the correct cutting tools for the material and desired finish is essential.

- In-Process Inspections: Regularly measuring and inspecting the workpiece during machining allows for timely adjustments and corrections.

5. What safety precautions must be observed when operating an Inside Barrel Lathe?

Safety is paramount when operating Inside Barrel Lathes:

- Proper PPE: Wearing safety glasses, earplugs, and appropriate clothing is mandatory.

- Guarding and Shielding: Machine guards and shields prevent contact with rotating parts and flying chips.

- Secure Workpieces: Ensuring that workpieces are securely mounted minimizes accidents.

6. How do you maintain and troubleshoot Inside Barrel Lathes?

Regular maintenance and troubleshooting are crucial for lathe longevity and performance:

- Daily Maintenance: Cleaning, lubricating, and inspecting the machine ensures smooth operation.

- Preventive Maintenance: Scheduled inspections and replacements of wear parts prevent breakdowns.

- Troubleshooting: Diagnosing and resolving machine issues promptly minimizes downtime.

7. What are the common machining defects that can occur in Inside Barrel Lathe operations?

Common defects include:

- Bore Taper: Non-uniform bore diameter due to machine or tooling misalignment.

- Bellmouth: Widened bore entrance caused by excessive cutting force or worn tools.

- Chatter Marks: Surface imperfections resulting from machine or tool vibrations.

8. What is the role of coolants in Inside Barrel Lathe machining?

- Cooling and Lubrication: Coolants reduce friction and dissipate heat, improving tool life and surface finish.

- Chip Removal: Coolants flush chips away from the cutting zone, preventing re-cutting and enhancing tool performance.

9. How do you handle out-of-tolerance conditions during Inside Barrel Lathe operations?

When machined barrels do not meet specifications:

- Identify the Cause: Determine the root cause of the error, whether it’s machine, tooling, or workpiece-related.

- Make Adjustments: Recalibrate the machine, replace worn tools, or adjust cutting parameters as necessary.

- Repeat Inspections: Verify that the corrective actions have resolved the issue and the barrels meet tolerance requirements.

10. How do you stay updated on the latest Inside Barrel Lathe technologies and advancements?

I actively engage in professional development to stay informed about new technologies and advancements:

- Industry Events: Attending conferences and trade shows provides exposure to emerging trends and innovations.

- Technical Training: Participating in training programs offered by manufacturers and industry experts.

- Publications and Journals: Regularly reviewing industry publications and technical journals provides insights into the latest developments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Inside Barrel Lathe Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Inside Barrel Lathe Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Inside Barrel Lathe Operators are responsible for operating a lathe to bore and finish the inside of barrels. They use a variety of cutting tools and techniques to create smooth, accurate bores. The key job responsibilities of an Inside Barrel Lathe Operator include:

1. Preparing the Lathe

The operator must first prepare the lathe for operation. This includes setting up the cutting tools, adjusting the speed and feed rate, and ensuring that the lathe is properly lubricated.

- Mounts and aligns various cutting tools on the lathe.

- Sets up and adjusts the lathe’s speed, feed rate, and lubrication system.

2. Loading and Unloading Barrels

The operator must then load the barrel onto the lathe. This is done carefully to avoid damaging the barrel or the lathe.

- Safely loads and unloads barrels onto the lathe using lifting equipment.

- Ensures proper alignment and secure mounting of barrels to prevent accidents or damage.

3. Boring the Barrel

Once the barrel is loaded, the operator can begin boring the inside. This is done by using a cutting tool to remove material from the inside of the barrel.

- Operates the lathe to bore and finish the inside of barrels according to specifications.

- Adjusts cutting tool depth and speed to achieve desired bore dimensions and surface finish.

4. Finishing the Bore

Once the bore is complete, the operator must finish it. This is done by using a variety of techniques to create a smooth, accurate surface.

- Uses various finishing techniques, such as reaming, honing, and polishing to achieve the desired bore quality.

- Regularly inspects the bore surface to ensure conformance to specifications.

5. Quality Control

The operator is responsible for ensuring that the barrels meet all quality standards. This includes checking the dimensions of the bore, the surface finish, and the overall quality of the barrel.

- Conducts quality control checks on the finished bores to ensure accuracy, smoothness, and adherence to specifications.

- Maintains records of all quality control inspections and reports any discrepancies or defects to supervisors.

6. Maintaining the Lathe

The operator is also responsible for maintaining the lathe. This includes cleaning the lathe, lubricating the moving parts, and making minor repairs.

- Performs routine maintenance on the lathe, including cleaning, lubrication, and minor repairs.

- Reports any major mechanical issues or malfunctions to the supervisor for prompt attention.

Interview Tips

To prepare for an interview for an Inside Barrel Lathe Operator position, you should:

1. Research the company and the position

This will help you understand the company’s culture and the specific requirements of the position.

- Visit the company’s website to learn about its history, products, and services.

- Read online reviews of the company to get an idea of its work environment and culture.

- Review the job description carefully to identify the key skills and experience required for the position.

2. Practice answering common interview questions

There are a number of common interview questions that you can expect to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and concisely.

- Prepare a brief introduction that highlights your relevant skills and experience.

- Develop specific examples of your accomplishments that demonstrate your ability to perform the key job responsibilities.

- Practice answering questions about your strengths, weaknesses, and career goals.

3. Be prepared to discuss your experience and skills

The interviewer will want to know about your experience and skills as they relate to the position. Be prepared to discuss your experience operating lathes, boring barrels, and finishing bores. You should also be able to explain your quality control procedures and your ability to maintain the lathe.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Highlight any experience or skills that are particularly relevant to the requirements of the position.

- Be prepared to answer questions about your work ethic, attention to detail, and ability to work independently.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you are respectful of their time.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Arrive at the interview location a few minutes early so that you have time to relax and compose yourself.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

5. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic about the position and who is positive about their ability to perform the job. Be sure to express your interest in the position and your confidence in your ability to succeed.

- Smile, make eye contact, and speak clearly and confidently.

- Be enthusiastic about the company and the position, and express your eagerness to contribute to the team.

- Maintain a positive attitude throughout the interview, even if you are asked difficult questions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Inside Barrel Lathe Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.