Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Inspecting Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

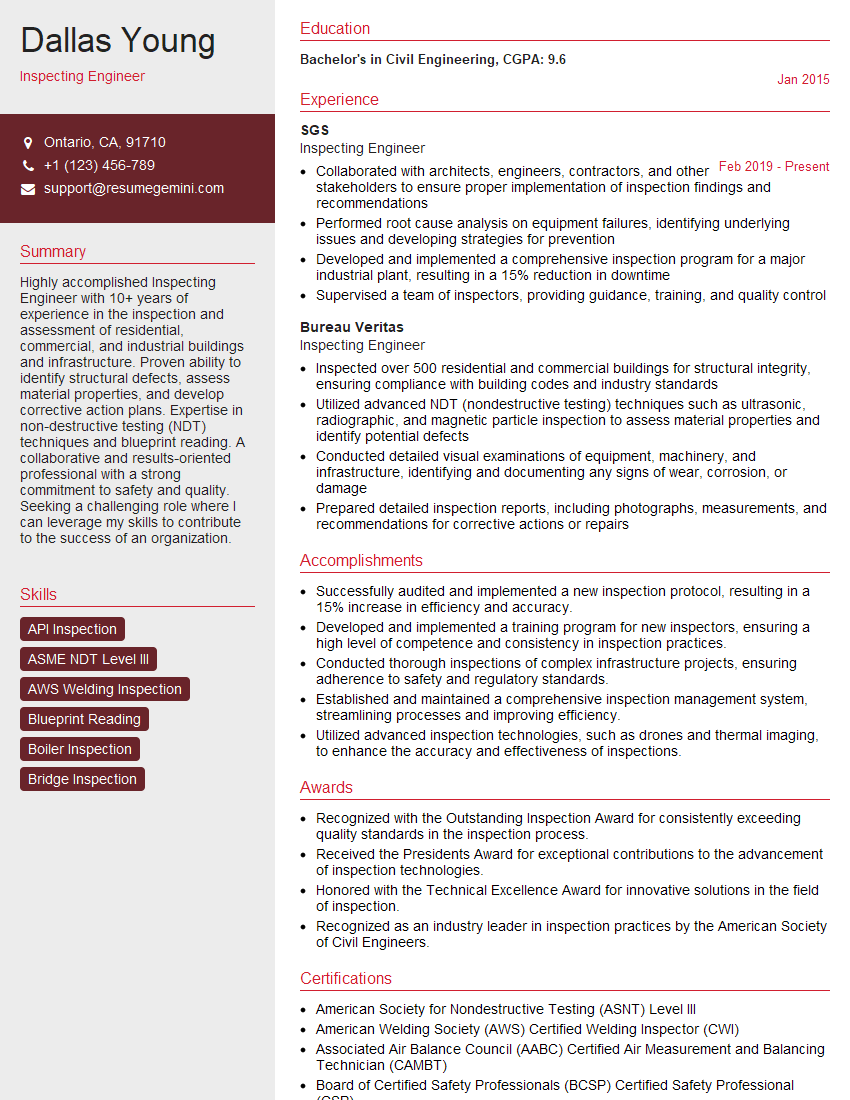

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Inspecting Engineer

1. How do you determine the appropriate inspection techniques for a given project?

In determining the appropriate inspection techniques for a given project, several factors must be considered:

- Project complexity: The complexity of the project will influence the level of inspection required. More complex projects will require more rigorous inspection techniques.

- Materials and components: The type of materials and components used in the project will also impact the inspection techniques. Different materials and components have different inspection requirements.

- Project schedule: The project schedule will also play a role in determining the inspection techniques. Shorter schedules may require faster inspection techniques.

- Budget: The budget for the project will also be a factor in determining the inspection techniques. More expensive inspection techniques may not be feasible for all projects.

2. What are some of the most common inspection methods used in the construction industry?

Non-Destructive Testing (NDT)

- Ultrasonic testing: Uses high-frequency sound waves to detect flaws in materials.

- Radiographic testing: Uses X-rays or gamma rays to detect flaws in materials.

- Magnetic particle testing: Uses magnetic particles to detect surface flaws in materials.

- Liquid penetrant testing: Uses a liquid penetrant to detect surface flaws in materials.

Destructive Testing

- Tensile testing: Measures the strength of a material by pulling it until it breaks.

- Compression testing: Measures the strength of a material by compressing it until it breaks.

- Shear testing: Measures the strength of a material by shearing it until it breaks.

- Bending testing: Measures the strength of a material by bending it until it breaks.

3. How do you write an effective inspection report?

An effective inspection report should include the following information:

- Executive summary: A brief overview of the inspection findings.

- Background information: The purpose of the inspection, the scope of the inspection, and the methods used.

- Inspection findings: A detailed description of the inspection findings, including any defects or deficiencies.

- Recommendations: Recommendations for corrective action.

- Conclusion: A summary of the inspection findings and recommendations.

4. What are the different types of welding inspections?

- Visual inspection: A visual examination of the weld to identify any defects or deficiencies.

- Non-destructive testing: Uses NDT methods to detect flaws in the weld.

- Destructive testing: Uses destructive methods to test the strength of the weld.

- Weld procedure qualification: A test to verify that the welding procedure is adequate for the intended application.

- Welder qualification: A test to verify that the welder is qualified to perform the welding.

5. What are the different types of building inspections?

- Pre-purchase inspection: An inspection performed before a property is purchased to identify any defects or deficiencies.

- Home inspection: An inspection performed on a home to identify any defects or deficiencies.

- Commercial building inspection: An inspection performed on a commercial building to identify any defects or deficiencies.

- Code compliance inspection: An inspection performed to verify that a building complies with the applicable building codes.

- Energy audit: An inspection performed to identify ways to improve the energy efficiency of a building.

6. What is the purpose of a Quality Control Plan (QCP)?

The purpose of a QCP is to define the quality control procedures that will be used on a project. The QCP should include the following information:

- Quality objectives: The quality objectives for the project.

- Quality control procedures: The quality control procedures that will be used to achieve the quality objectives.

- Inspection and testing requirements: The inspection and testing requirements that will be used to verify that the quality objectives are met.

- Non-conformance procedures: The procedures that will be used to address non-conformances.

- Quality records: The quality records that will be maintained to document the quality control process.

7. What are the different types of quality control inspections?

- In-process inspection: An inspection performed during the production process to identify any defects or deficiencies.

- Final inspection: An inspection performed at the end of the production process to identify any defects or deficiencies.

- In-service inspection: An inspection performed on a product or system after it has been put into service to identify any defects or deficiencies.

- Surveillance inspection: An inspection performed at regular intervals to verify that a product or system is being maintained in accordance with the applicable standards.

8. What are the benefits of using a quality management system?

- Improved quality: A quality management system can help to improve the quality of a product or service.

- Reduced costs: A quality management system can help to reduce costs by preventing defects and rework.

- Increased customer satisfaction: A quality management system can help to increase customer satisfaction by delivering a high-quality product or service.

- Improved efficiency: A quality management system can help to improve efficiency by streamlining processes and eliminating waste.

- Competitive advantage: A quality management system can help to give a company a competitive advantage by providing a high-quality product or service.

9. What are the different types of quality management systems?

- ISO 9001: A generic quality management system that can be used by any organization.

- ISO 14001: An environmental management system that helps organizations to reduce their environmental impact.

- OHSAS 18001: A health and safety management system that helps organizations to improve their health and safety performance.

- IATF 16949: A quality management system for the automotive industry.

- AS9100: A quality management system for the aerospace industry.

10. What are the key elements of a successful quality management system?

- Leadership: Top management must be committed to quality.

- Planning: The organization must have a clear plan for how to achieve its quality objectives.

- Implementation: The organization must implement its quality management system effectively.

- Measurement: The organization must measure its quality performance and identify areas for improvement.

- Review: The organization must regularly review its quality management system and make necessary changes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Inspecting Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Inspecting Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Inspecting Engineers are responsible for ensuring that products and services meet quality standards. They work in a variety of industries, including manufacturing, construction, and healthcare. Their duties include:1. Inspecting products and services

- Examining products and services to ensure that they meet specifications and quality standards

- Identifying and documenting defects or non-conformances

- Working with engineers and technicians to correct defects and improve quality

2. Developing and implementing inspection plans

- Creating inspection plans that outline the specific procedures and criteria to be used during inspections

- Ensuring that inspection plans are followed and that inspectors are properly trained

- Reviewing inspection data and making recommendations for improvements to the inspection process

3. Managing inspection teams

- Supervising and training inspectors

- Assigning inspection tasks and ensuring that they are completed on time and to a high standard

- Evaluating the performance of inspectors and providing feedback

4. Reporting on inspection results

- Preparing inspection reports that document the findings of inspections

- Communicating inspection results to management and other stakeholders

- Making recommendations for corrective action based on inspection findings

Interview Tips

To prepare for an interview for an Inspecting Engineer position, the following tips can be helpful:1. Research the company and the position

- Visit the company’s website to learn about its products, services, and culture.

- Read the job description carefully to understand the specific requirements of the position.

- Learn about the industry and the specific market in which the company operates.

2. Practice your answers to common interview questions

- Develop clear and concise answers to questions about your skills, experience, and qualifications.

- Use the STAR method to structure your answers, providing specific examples of your work.

- Be prepared to discuss your knowledge of inspection techniques, quality standards, and industry best practices.

3. Prepare questions to ask the interviewer

- Asking thoughtful questions shows that you are interested in the position and the company.

- Prepare questions about the company’s quality control process, the role of the Inspecting Engineer, and the opportunities for professional development.

4. Dress professionally and arrive on time

- First impressions matter, so dress professionally for your interview.

- Arrive on time to show that you are respectful of the interviewer’s time.

5. Be confident and enthusiastic

- Believe in your skills and abilities, and show the interviewer that you are excited about the opportunity.

- Be positive and enthusiastic throughout the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Inspecting Engineer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.