Feeling lost in a sea of interview questions? Landed that dream interview for Inspecting Machine Adjuster but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Inspecting Machine Adjuster interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

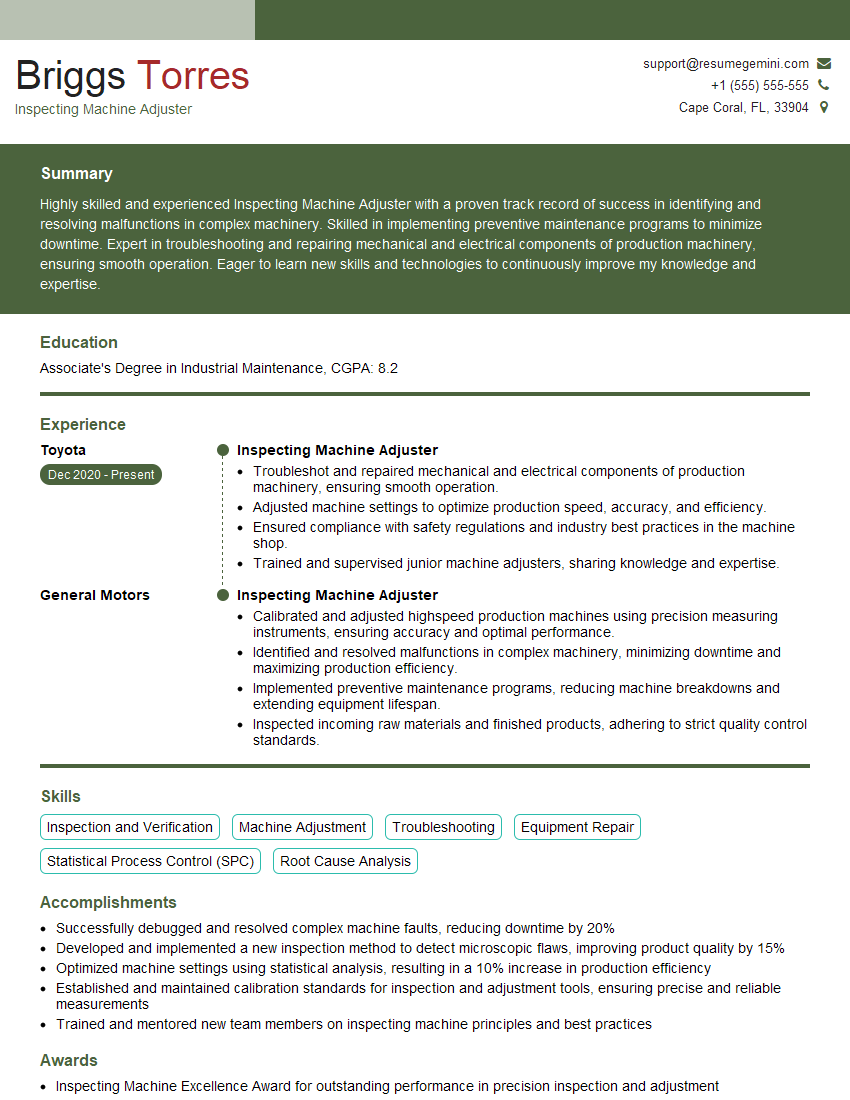

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Inspecting Machine Adjuster

1. Describe the key responsibilities of an Inspecting Machine Adjuster?

The key responsibilities of an Inspecting Machine Adjuster include:

- Inspecting and testing machines to ensure they meet quality standards

- Adjusting and calibrating machines to optimize performance

- Troubleshooting and repairing machine malfunctions

- Maintaining and updating machine records

- Collaborating with other team members to ensure smooth machine operation

2. What are the most important technical skills required for an Inspecting Machine Adjuster?

The most important technical skills required for an Inspecting Machine Adjuster include:

- Strong knowledge of mechanical and electrical systems

- Proficient in using precision measuring tools and equipment

- Ability to interpret technical drawings and schematics

- Experience in troubleshooting and repairing machinery

- Familiarity with quality control and inspection procedures

3. What are the essential soft skills for an Inspecting Machine Adjuster?

The essential soft skills for an Inspecting Machine Adjuster include:

- Excellent communication and interpersonal skills

- Strong attention to detail and accuracy

- Ability to work independently and as part of a team

- Problem-solving and critical thinking skills

- Commitment to safety and quality

4. What are the different types of machines that an Inspecting Machine Adjuster may be required to work on?

An Inspecting Machine Adjuster may be required to work on a wide variety of machines, including:

- Production machines

- Assembly machines

- Packaging machines

- Conveyor systems

- Automated equipment

5. What is the importance of preventive maintenance for an Inspecting Machine Adjuster?

Preventive maintenance is crucial for Inspecting Machine Adjusters because it:

- Reduces the risk of machine breakdowns and production delays

- Extends the lifespan of machines

- Improves machine efficiency and performance

- Ensures the safety of operators and workers

- Helps in detecting potential problems early on

6. What are the different types of inspection methods used by Inspecting Machine Adjusters?

Inspecting Machine Adjusters use a variety of inspection methods, including:

- Visual inspections

- Dimensional inspections

- Functional inspections

- Electrical inspections

- Non-destructive testing (NDT)

7. What are the common troubleshooting techniques used by Inspecting Machine Adjusters?

Common troubleshooting techniques used by Inspecting Machine Adjusters include:

- Identifying the problem

- Gathering data and information

- Analyzing the data

- Developing and implementing a solution

- Testing the solution

8. What are the safety protocols that Inspecting Machine Adjusters must follow?

Inspecting Machine Adjusters must follow strict safety protocols, including:

- Wearing appropriate personal protective equipment (PPE)

- Following lockout/tagout procedures

- Using machines safely

- Being aware of potential hazards

- Reporting any unsafe conditions

9. How do Inspecting Machine Adjusters contribute to the overall quality of products?

Inspecting Machine Adjusters contribute to the overall quality of products by:

- Ensuring that machines are operating correctly

- Identifying and correcting defects

- Maintaining quality standards

- Working with other team members to improve processes

- Providing feedback on machine performance

10. What are the career growth opportunities for Inspecting Machine Adjusters?

Inspecting Machine Adjusters can advance their careers by:

- Gaining experience and expertise in different areas

- Becoming certified in quality control or machine maintenance

- Moving into supervisory or management roles

- Specializing in a particular type of machine or industry

- Starting their own businesses

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Inspecting Machine Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Inspecting Machine Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Inspecting Machine Adjuster, also known as a Tooling Technician, plays a crucial role in ensuring that machines operate at optimal efficiency and produce high-quality products. Key job responsibilities include:

1. Machine Setup and Adjustment

Setting up, adjusting, and calibrating machines according to engineering specifications and production requirements.

- Ensuring precision, accuracy, and proper functioning of machines.

- Monitoring and adjusting machine settings to optimize performance and meet quality standards.

2. Inspection and Quality Control

Inspecting machines, components, and finished products for defects, wear, and proper functionality.

- Identifying and troubleshooting any issues that may affect product quality or machine operation.

- Adhering to established inspection procedures and reporting any identified discrepancies promptly.

3. Tooling and Fixture Maintenance

Maintaining, inspecting, and repairing tooling, fixtures, and jigs used in production processes.

- Ensuring that tooling is sharp, properly aligned, and in good working condition.

- Performing regular preventive maintenance checks to minimize downtime and extend tool life.

4. Troubleshooting and Problem Solving

Diagnosing and resolving machine problems, breakdowns, or malfunctions.

- Using technical knowledge and problem-solving skills to identify the root cause of issues.

- Implementing solutions to restore machine functionality and minimize production delays.

Interview Tips

With a clear understanding of the key job responsibilities, here are some interview preparation tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company’s industry, products, and culture. This will help you understand their business goals and the specific role of the Inspecting Machine Adjuster within the organization.

- Visit the company’s website, LinkedIn profile, and industry news articles.

- Learn about the specific products or services produced by the company.

2. Highlight Relevant Experience and Skills

Tailor your resume and cover letter to showcase your skills and experience that are directly relevant to the Inspecting Machine Adjuster role. Quantify your accomplishments whenever possible.

- Emphasize your experience in machine setup, adjustment, inspection, and troubleshooting.

- Provide examples of how you have improved machine efficiency, reduced downtime, or resolved complex problems.

3. Practice Your Answers

Practice answering common interview questions related to your skills, experience, and motivations. This will help you articulate your responses clearly and confidently.

- Prepare examples of situations where you have successfully used your technical knowledge to solve problems.

- Consider questions related to your understanding of quality control processes and your ability to work in a fast-paced manufacturing environment.

4. Dress Professionally and Arrive Punctually

Make a positive first impression by dressing professionally and arriving for the interview on time. Punctuality shows respect for the interviewer’s time and conveys your seriousness about the position.

- Choose attire that is clean, pressed, and appropriate for a manufacturing or industrial setting.

- Allow ample time for travel and finding the interview location to avoid any delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Inspecting Machine Adjuster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!