Are you gearing up for a career in Inspector Packer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Inspector Packer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

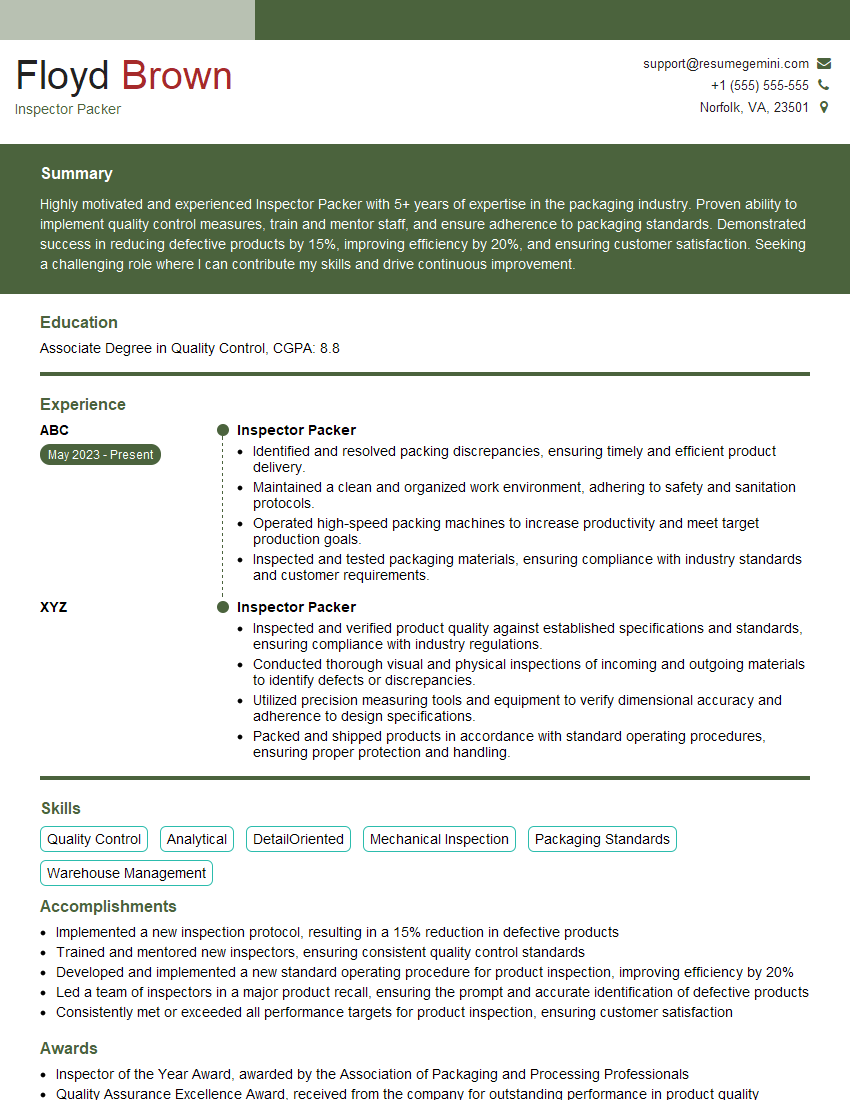

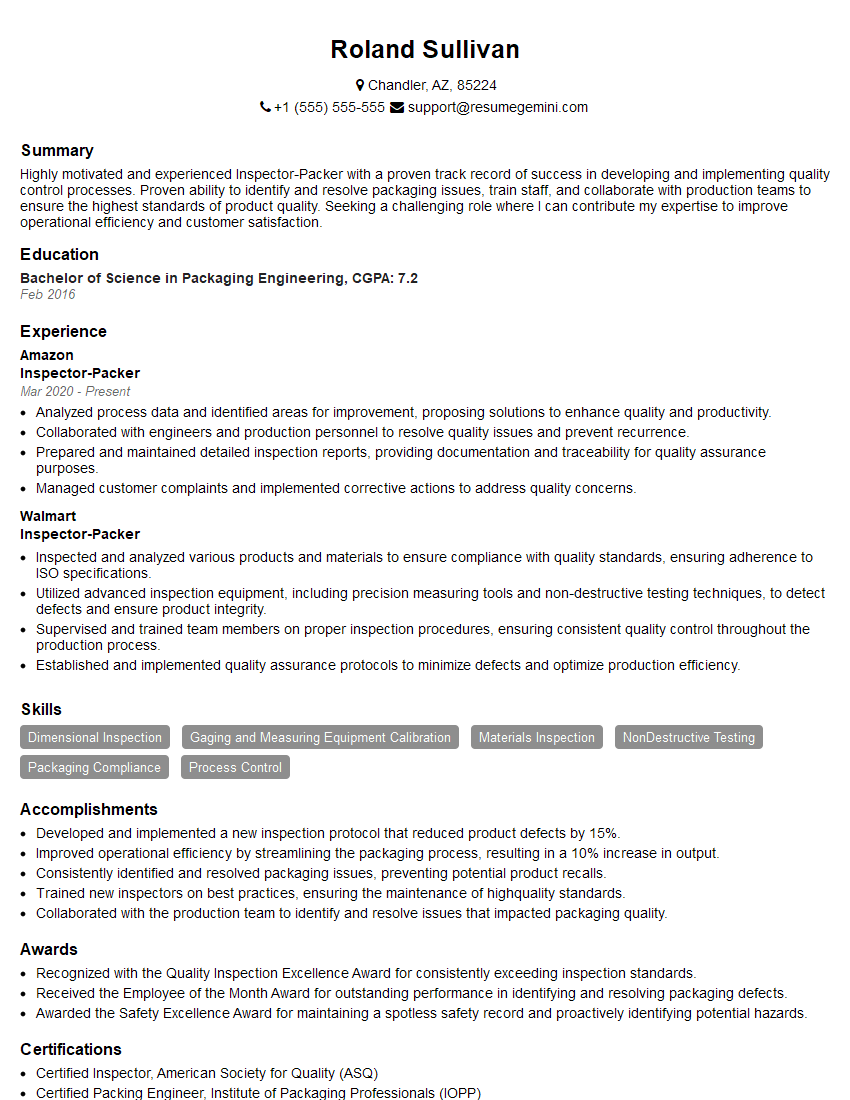

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Inspector Packer

1. What are the key responsibilities of an Inspector Packer?

As an Inspector Packer, my primary responsibilities would be:

- Inspecting incoming raw materials and finished products to ensure quality standards are met

- Packing and packaging products according to specifications and industry regulations

2. Describe the different types of packaging materials you have experience working with?

Paper and Cardboard

- Corrugated cardboard

- Kraft paper

Plastic

- Polyethylene (PE)

- Polypropylene (PP)

Metal

- Aluminum

- Steel

3. What are the key quality control measures you follow when inspecting products?

I follow a comprehensive set of quality control measures to ensure product integrity, including:

- Visual inspection for defects, damage, or contamination

- Dimensional measurements to verify compliance with specifications

- Testing for weight, strength, and other relevant properties

4. What are the common packaging defects you encounter and how do you address them?

Some common packaging defects I encounter include:

- Tears or punctures in packaging materials

- Improperly sealed packages

- Mislabeled or damaged products

I address these defects by:

- Rejecting non-conforming packages

- Repairing minor defects if possible

- Documenting and reporting any significant defects

5. What are the safety protocols you follow when working with packaging materials?

I am committed to maintaining a safe work environment and adhere to the following safety protocols:

- Wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses

- Using sharp objects with care and disposing of them properly

- Handling heavy objects safely and using mechanical aids when necessary

6. How do you stay updated with industry best practices and regulations related to packaging?

I stay abreast of industry best practices and regulations through:

- Attending industry events and conferences

- Reading trade publications and technical journals

- Participating in online forums and discussions

7. What are the challenges you have faced in your previous role as an Inspector Packer and how did you overcome them?

In my previous role, I faced the challenge of maintaining high quality standards while meeting demanding production schedules. To overcome this, I:

- Collaborated with production staff to identify potential bottlenecks and implement process improvements

- Developed and implemented a system for prioritizing inspections based on product criticality

- Trained and mentored new inspectors to ensure consistent quality standards

8. How do you handle discrepancies between inspection results and production records?

I handle discrepancies in the following manner:

- Verify the discrepancy by re-inspecting the product or reviewing production records

- Communicate the discrepancy to the relevant parties, such as production supervisors or quality managers

- Investigate the root cause of the discrepancy and recommend corrective actions

9. What is your understanding of the role of an Inspector Packer in maintaining compliance with industry standards?

As an Inspector Packer, I play a crucial role in ensuring compliance with industry standards by:

- Inspecting products to verify they meet the required specifications

- Rejecting non-conforming products to prevent them from entering the supply chain

- Maintaining accurate records of inspections and product quality

10. Describe your experience with using quality control software or tools?

I am proficient in using various quality control software and tools, including:

- Statistical process control (SPC) charts

- Measurement systems analysis (MSA)

- Product lifecycle management (PLM) systems

I use these tools to:

- Monitor product quality trends and identify potential issues

- Analyze and improve measurement systems

- Manage product data and documentation

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Inspector Packer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Inspector Packer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Inspector Packer plays a vital role in quality control and packaging for a variety of industries such as manufacturing, food processing, and pharmaceuticals. The key responsibilities of an Inspector Packer include:

1. Inspection of Products

Inspect raw materials, components and finished products for quality, conformance to specifications, and adherence to regulatory standards.

- Check for defects, damage, contamination, or any discrepancies against established criteria.

- Verify product labeling, packaging, and documentation for accuracy and compliance.

2. Packaging and Labeling

Pack and label products according to specified packaging procedures and guidelines.

- Select the appropriate packaging materials, such as boxes, cartons, or containers.

- Pack products securely, ensuring protection during transport and storage.

- Apply labels, barcodes, or other identification markings as required.

3. Quality Control

Monitor and maintain quality standards throughout the production process.

- Identify and report any defects or non-conformances to supervisors.

- Document inspection findings and maintain quality control records.

- Participate in quality improvement initiatives and follow established quality management systems.

4. Other Responsibilities

Perform other related tasks as assigned, such as:

- Assist with inventory control and stock management.

- Operate machinery or equipment used in the inspection or packaging process.

- Maintain a clean and organized work area.

Interview Tips

To help candidates ace the interview for an Inspector Packer role, the following tips and hacks may be helpful:

1. Research the Company and Industry

Demonstrate your interest and knowledge by thoroughly researching the company, its products or services, and the industry in which it operates.

- Visit the company’s website, read industry publications, and consult with professionals in the field.

- Familiarize yourself with the company’s mission, values, and specific job requirements.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the Inspector Packer role.

- Quantify your accomplishments using specific metrics and data whenever possible.

- Use examples from past work experiences to demonstrate your ability to inspect, pack, and maintain quality standards.

3. Practice Answering Common Interview Questions

Prepare for common interview questions related to the role, such as:

- Tell me about your experience in inspecting and packaging products.

- How do you ensure that products meet quality standards?

- What is your approach to identifying and resolving quality issues?

- How do you stay updated on industry best practices and regulatory requirements?

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Dress professionally, arrive on time, and be prepared to articulate your interest in the role and the company.

- Show your passion for quality and attention to detail.

- Be confident in your abilities and demonstrate a willingness to learn and grow within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Inspector Packer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!