Feeling lost in a sea of interview questions? Landed that dream interview for Instrument and Controls Technician (I & C Technician) but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Instrument and Controls Technician (I & C Technician) interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

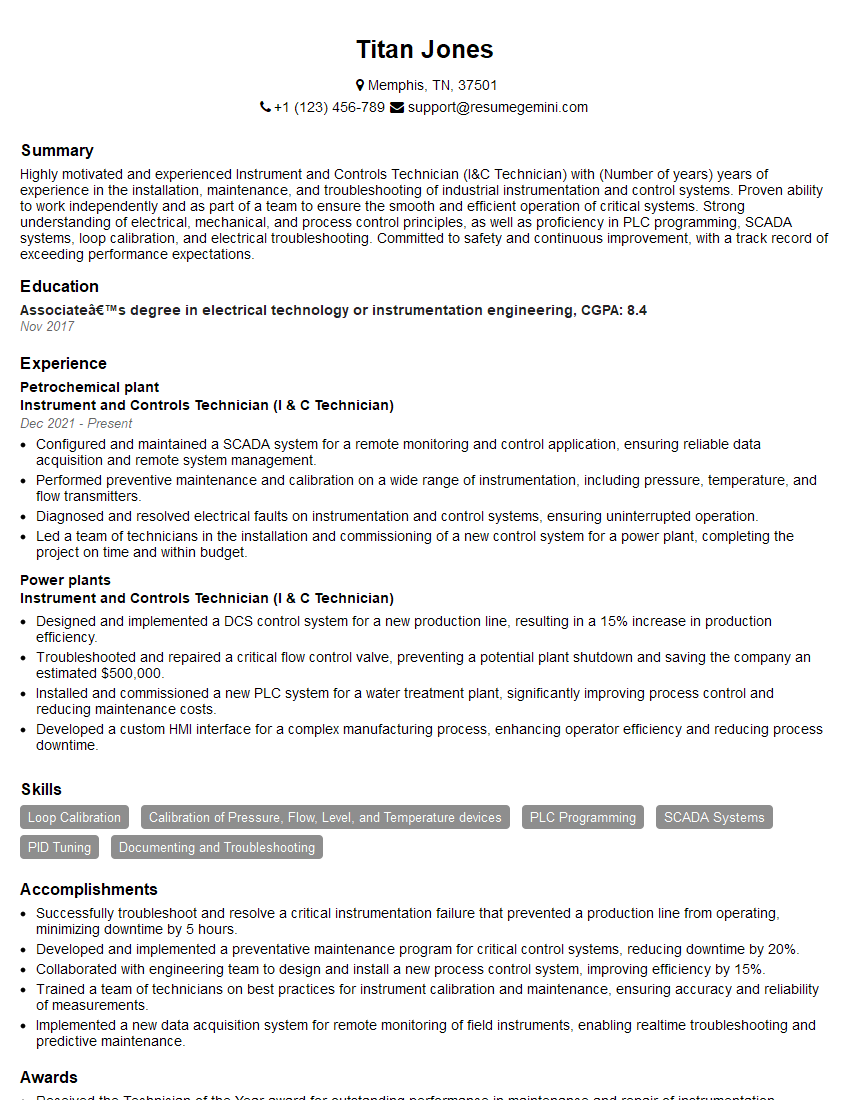

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument and Controls Technician (I & C Technician)

1. Explain the working principle of a pressure transmitter?

A pressure transmitter converts the pressure signal from a process into an electrical signal that can be transmitted and measured. Here’s how it works:

- Sensing Element: The pressure transmitter contains a pressure-sensing element, typically a diaphragm, bourdon tube, or piezoresistive sensor.

- Pressure Application: The pressure signal from the process is applied to the sensing element.

- Pressure Detection: The sensing element responds to the pressure and deforms, causing a change in its physical characteristics.

- Signal Conversion: The deformation of the sensing element is converted into an electrical signal. Some common signal types include 4-20mA, 0-10V, or HART.

- Signal Transmission: The converted electrical signal is transmitted to a receiver or controller for monitoring and control purposes.

2. Describe the difference between a temperature sensor and a temperature transmitter?

Temperature Sensor

- Measures temperature and converts it into an electrical signal.

- No display or signal processing capabilities.

- Usually provides raw temperature data.

Temperature Transmitter

- Measures temperature, converts it into an electrical signal, and transmits it.

- Often has a display for local monitoring.

- May offer additional features like signal filtering, linearization, and diagnostics.

3. Explain the importance of calibration in instrumentation and controls?

- Accuracy and Reliability: Calibration ensures that instruments and control systems provide accurate and reliable measurements, ensuring the proper operation of processes.

- Traceability: Proper calibration establishes a traceable link between the instrument and a known standard, ensuring the validity of measurements.

- Compliance: Calibration helps meet industry standards and regulatory requirements, such as ISO 9001 or FDA regulations.

- Process Optimization: Accurate calibration allows for precise control and optimization of processes, leading to increased efficiency and reduced costs.

- Safety: Correct calibration helps ensure the safety of personnel and equipment by providing reliable measurements for critical parameters.

4. What are the steps involved in troubleshooting a faulty control valve?

- Visual Inspection: Check for any obvious signs of damage or leaks.

- Electrical Testing: Verify the electrical connections and power supply to the valve.

- Pneumatic Testing: Ensure proper air pressure and supply to the valve actuator.

- Mechanical Testing: Manually operate the valve to check for any binding or excessive resistance.

- Loop Testing: Use a loop tester to check the signal from the controller to the valve.

- Diagnostic Software: If available, utilize diagnostic software to identify errors or communication issues.

- Valve Disassembly: If necessary, disassemble the valve to inspect internal components for wear or damage.

5. Describe the different types of flowmeters and their applications?

- Differential Pressure Flowmeters: Venturi, orifice plate, pitot tube (for measuring liquid or gas flow).

- Positive Displacement Flowmeters: Oval gear, nutating disk (for measuring liquid flow with high accuracy).

- Turbine Flowmeters: Impeller and propeller (for measuring liquid or gas flow with low pressure drop).

- Ultrasonic Flowmeters: Utilizes ultrasonic waves (for non-invasive measurement of liquid or gas flow).

- Magnetic Flowmeters: Measures the voltage induced by moving conductive fluid in a magnetic field (for measuring liquid flow).

6. Explain the function of a programmable logic controller (PLC) in an industrial automation system?

- Control Logic: A PLC executes user-defined logic programs to control the sequence of operations in an automation system.

- Input/Output Interface: It connects to input and output devices to receive signals from sensors and send control signals to actuators.

- Data Acquisition and Storage: A PLC can collect data from sensors and store it for future analysis or monitoring.

- Communication: PLCs can communicate with other devices, such as HMI screens or SCADA systems, for data exchange and visualization.

- Flexibility and Scalability: PLCs offer flexibility and scalability, allowing for easy modification of logic programs and expansion of the system.

7. What are the key responsibilities of an Instrument and Controls Technician?

- Installation and Maintenance: Installing, calibrating, and maintaining instruments and control systems.

- Troubleshooting and Repair: Diagnosing and repairing faults in instrumentation and controls.

- System Integration: Integrating new or modified instruments and controls into existing systems.

- Documentation: Maintaining accurate documentation of all work performed.

- Safety Compliance: Ensuring compliance with safety regulations and industry standards.

- Training and Support: Providing training and support to operators and maintenance personnel.

8. What software tools are commonly used in instrumentation and controls?

- Calibration Software: For managing calibration records, generating calibration certificates, and tracking instrument history.

- SCADA Systems: For monitoring, controlling, and visualizing processes in real-time.

- Configuration Software: For programming PLCs, configuring instruments, and setting up communication networks.

- Data Acquisition Software: For collecting and analyzing data from instruments and sensors.

- Instrument Management Software: For organizing and tracking inventory of instruments, managing maintenance schedules, and generating reports.

9. Describe a challenging instrumentation or controls project you have worked on?

In a recent project, my team was tasked with implementing a new temperature control system for a large industrial furnace. The previous system was outdated and unreliable, leading to inconsistent product quality and increased maintenance costs. Our goal was to design and install a new system that would provide precise temperature control, reduce downtime, and improve product quality.

We conducted a thorough assessment of the existing system and identified its limitations. We then researched different temperature control technologies and selected a distributed control system (DCS) that offered advanced features such as PID control, data logging, and remote monitoring. We worked closely with the furnace manufacturer and electrical contractors to design the new system’s architecture and ensure proper integration with the existing equipment.

The project required extensive planning, coordination, and testing. We installed new temperature sensors, actuators, and control panels, and configured the DCS to meet the specific requirements of the furnace. We also provided training to the operators and maintenance personnel on the new system’s operation and maintenance.

The successful implementation of the new temperature control system resulted in significant improvements in product quality, reduced downtime, and increased energy efficiency. The furnace now operates at a consistent temperature, producing higher-quality products with fewer defects. The DCS provides real-time monitoring and data logging, allowing operators to track temperature trends and make informed decisions.

10. How do you stay up-to-date with the latest advancements in instrumentation and controls?

- Technical Publications: Subscribing to industry magazines, journals, and technical white papers.

- Webinars and Conferences: Attending industry webinars and conferences to learn about new technologies and trends.

- Training and Certification: Pursuing professional training and certifications from recognized organizations.

- Online Resources: Accessing online forums, discussion groups, and technical articles.

- Collaboration with Experts: Networking with other professionals in the field and sharing knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument and Controls Technician (I & C Technician).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument and Controls Technician (I & C Technician)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Instrument and Controls Technicians are responsible for the maintenance, calibration, troubleshooting and repair of instruments and control systems used in a variety of industrial and commercial settings. Some of their key responsibilities include:

1. Instrument Maintenance and Calibration

• Performing regular maintenance and calibration of instruments such as pressure gauges, temperature sensors, flow meters, and control valves.

• Ensuring that instruments are functioning properly and accurately.

2. Troubleshooting and Repair

• Troubleshooting and repairing instrumentation and control systems.

• Identifying and resolving problems with sensors, transmitters, controllers, and other components.

3. System Installation and Commissioning

• Installing and commissioning new instrumentation and control systems.

• Verifying that systems are operating properly and meet specifications.

4. Documentation and Record Keeping

• Maintaining documentation on instrument maintenance, calibration, and repairs.

• Keeping records of system performance and troubleshooting activities.

Interview Tips

Preparing for an interview for an Instrument and Controls Technician position can seem overwhelming, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and the Position

• Take the time to research the company and the specific position you are applying for.

• This will help you understand the company’s culture, values, and the specific responsibilities of the role.

2. Practice Your Answers to Common Interview Questions

• Practice answering common interview questions related to your skills, experience, and qualifications.

• For example, you may be asked about your experience with specific instrumentation and control systems, your troubleshooting abilities, or your knowledge of industry standards.

3. Highlight Your Relevant Skills and Experience

• In your interview, be sure to highlight your relevant skills and experience that match the job requirements.

• For example, if the job description emphasizes troubleshooting skills, be sure to provide specific examples of your troubleshooting experience.

4. Be Prepared to Talk About Your Safety Knowledge

• Instrument and Controls Technicians often work in hazardous environments, so it is important to be prepared to talk about your safety knowledge and practices.

• For example, you may be asked about your experience with lockout/tagout procedures or your knowledge of hazardous materials handling.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Instrument and Controls Technician (I & C Technician) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!