Are you gearing up for a career in Instrument and Controls Technician? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Instrument and Controls Technician and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

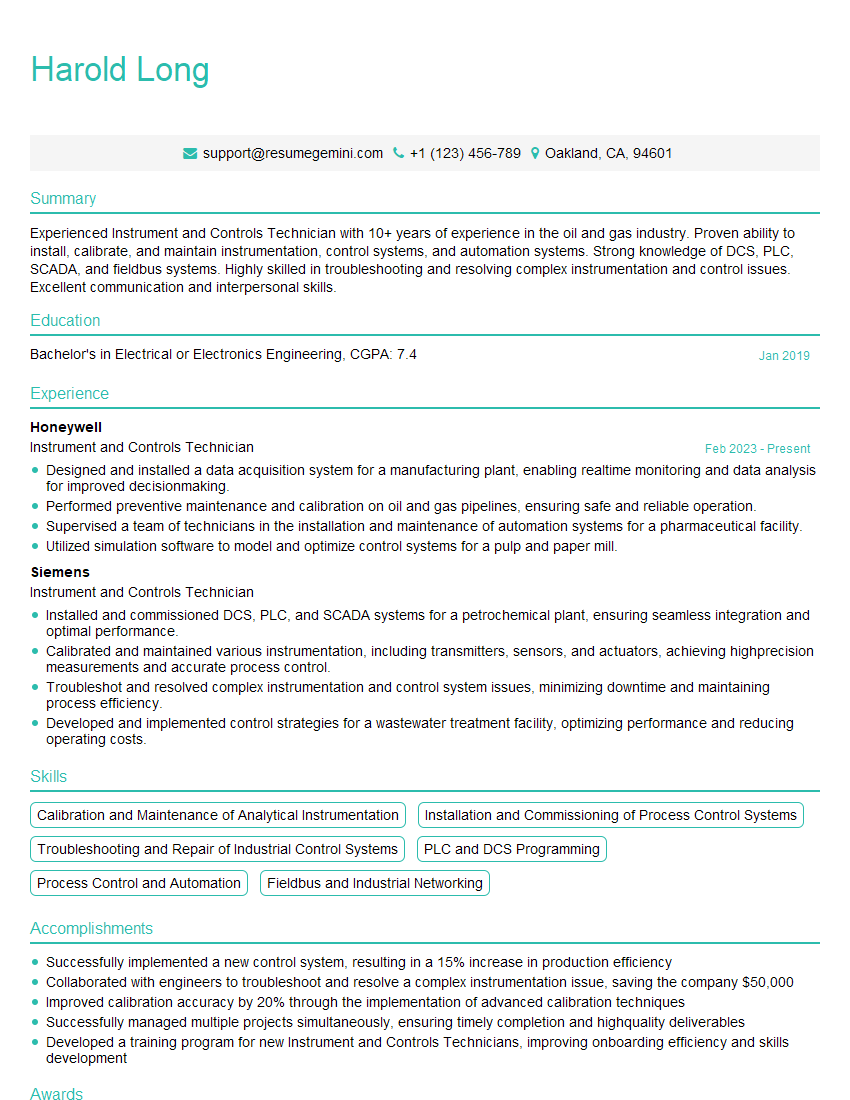

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument and Controls Technician

1. Explain the concept of calibration in instrumentation and control systems?

Calibration is the process of adjusting a measuring instrument or control system to match a known standard. It involves verifying the accuracy and precision of a device by comparing its output to a known input. The calibration process ensures that the device meets the specified accuracy and performance requirements and provides reliable measurements or control actions.

- Ensures accuracy and reliability of measurement devices

- Compares device output to a known input standard

- Adjusts the device to meet specified performance requirements

- Maintains the integrity of the measurement and control system

2. Describe the different types of sensors used in instrumentation and their applications?

Temperature sensors

- Thermocouples: Measure temperature by detecting the voltage generated between two dissimilar metals when heated

- Resistance temperature detectors (RTDs): Measure temperature by detecting the change in resistance of a conductor with temperature

- Thermistors: Measure temperature by detecting the change in resistance of a semiconductor material with temperature

Pressure sensors

- Strain gauges: Measure pressure by detecting the strain on a diaphragm or other deformable element

- Piezoelectric sensors: Measure pressure by detecting the electrical charge generated by a piezoelectric material when deformed

- Capacitive sensors: Measure pressure by detecting the change in capacitance between two plates when pressure is applied

Flow sensors

- Turbine flow meters: Measure flow rate by detecting the rotation of a turbine in the flow path

- Magnetic flow meters: Measure flow rate by detecting the voltage generated by a magnetic field across the flow path

- Ultrasonic flow meters: Measure flow rate by detecting the transit time of ultrasonic waves through the flow path

3. Explain the loop control structure in instrumentation and control systems?

A control loop is a closed-loop feedback system that regulates a process variable to a desired setpoint. It consists of three main components:

- Sensor: Measures the process variable and converts it into an electrical signal

- Controller: Compares the measured value to the setpoint and generates an error signal

- Actuator: Receives the error signal from the controller and adjusts the process variable to match the setpoint

Control loops are used to maintain stable and desired conditions in various processes, such as temperature control, pressure control, and flow control.

4. Discuss the role of PLCs (Programmable Logic Controllers) in industrial automation?

PLCs are industrial computers that are designed for automating industrial processes. They provide a flexible and programmable platform for controlling and monitoring various machines, devices, and systems.

- Provide real-time control and monitoring of industrial processes

- Programmable using ladder logic or other programming languages

- Control a wide range of I/O devices, including sensors, actuators, and motors

- Monitor and record process data for analysis and optimization

5. Describe the principles of operation of a PID (Proportional-Integral-Derivative) controller?

A PID controller is a type of feedback controller that uses three control actions to minimize the error between a desired setpoint and a measured process variable:

- Proportional (P): Corrects the error immediately by applying a control action proportional to the error magnitude

- Integral (I): Eliminates steady-state error by accumulating the error over time and applying a control action proportional to the accumulated error

- Derivative (D): Anticipates future changes in the error by applying a control action proportional to the rate of change of the error

PID controllers are widely used in industrial automation to achieve precise and stable control of various processes.

6. Explain the concept of data acquisition and its importance in instrumentation and control systems?

Data acquisition is the process of collecting and converting analog or digital signals from sensors into digital data that can be processed, stored, or transmitted. It plays a crucial role in instrumentation and control systems by:

- Providing real-time information on process variables

- Enabling monitoring, analysis, and visualization of process data

- Facilitating control actions based on measured process variables

- Supporting historical data storage for performance analysis and troubleshooting

7. Describe the different types of communication protocols used in industrial automation?

- Fieldbus protocols: Profibus, Modbus, CANbus, DeviceNet

- Industrial Ethernet protocols: Ethernet/IP, PROFINET, EtherCAT

- Wireless protocols: Wi-Fi, Bluetooth, Zigbee

These protocols provide standardized methods for communication between devices, sensors, controllers, and other components within an industrial automation system.

8. Explain the importance of safety considerations in instrumentation and control systems?

Safety in instrumentation and control systems is paramount to prevent potential hazards and ensure the well-being of personnel, equipment, and the environment.

- Implement safety features such as interlocks, alarms, and emergency shutdown systems

- Follow industry standards and regulations related to safety

- Conduct risk assessments and implement mitigation measures

- Provide proper training and documentation on safety procedures

9. Describe the role of calibration and maintenance in ensuring accurate and reliable instrumentation and control systems?

Calibration and maintenance are essential for maintaining the accuracy, reliability, and performance of instrumentation and control systems.

- Calibration: Regular calibration ensures that sensors, actuators, and other devices are measuring and controlling correctly

- Maintenance: Routine maintenance includes cleaning, inspection, and repair of components to prevent failures

Proper calibration and maintenance extend the lifespan of equipment, improve system performance, and minimize downtime.

10. How do you stay updated with the latest advancements in instrumentation and control technology?

- Attend industry conferences and workshops

- Read technical journals and articles

- Explore online resources and forums

- Participate in professional development programs

- Network with industry experts

Continuous learning is crucial in this rapidly evolving field to stay abreast of new technologies, methods, and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument and Controls Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument and Controls Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Instrument and Controls Technicians play a vital role in the operation and maintenance of various industrial plants and facilities. Their key job responsibilities include:

1. Installation, Maintenance, and Repair

Installing, maintaining, and repairing instrumentation and control systems, including sensors, transmitters, controllers, and actuators.

- Troubleshooting and diagnosing faults in instrumentation and control systems

- Replacing faulty components and calibrating instruments

2. System Analysis and Design

Analyzing and designing instrumentation and control systems to meet specific operational requirements.

- Selecting and specifying instrumentation and components

- Developing control strategies and tuning control loops

3. Process Control and Optimization

Monitoring and controlling process variables to ensure optimal performance and efficiency.

- Adjusting control parameters and tuning controllers

- Identifying and implementing process improvements

4. Electrical and Mechanical Work

Performing electrical and mechanical work related to instrumentation and control systems.

- Installing and wiring electrical components

- Fabricating and assembling mechanical parts

Interview Tips

Preparing effectively for an interview can significantly increase your chances of success. Here are some tips to help you ace your Instrument and Controls Technician interview:

1. Research the Company and Position

Take the time to learn about the company’s industry, products, and culture. Research the specific role you are applying for and its responsibilities.

- Visit the company’s website and social media pages

- Read industry publications and news articles

2. Practice Your Skills

Review your technical skills and knowledge related to instrumentation and control systems. Practice answering common interview questions about your experience and qualifications.

- Use online resources or books to refresh your memory

- Consider mock interviews with a friend or family member

3. Highlight Your Experience

When describing your experience, use specific examples to demonstrate your skills and abilities. Quantify your accomplishments whenever possible to showcase your impact.

- Use the STAR method (Situation, Task, Action, Result)

- Prepare stories that highlight your technical expertise

4. Be Enthusiastic and Professional

Show enthusiasm for the role and the industry. Dress professionally and arrive on time for your interview. Maintain eye contact and speak clearly.

- Ask thoughtful questions during the interview

- Be prepared to talk about your career goals and aspirations

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Instrument and Controls Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.