Feeling lost in a sea of interview questions? Landed that dream interview for Instrument and Electrical Technician (I&E Tech) but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Instrument and Electrical Technician (I&E Tech) interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

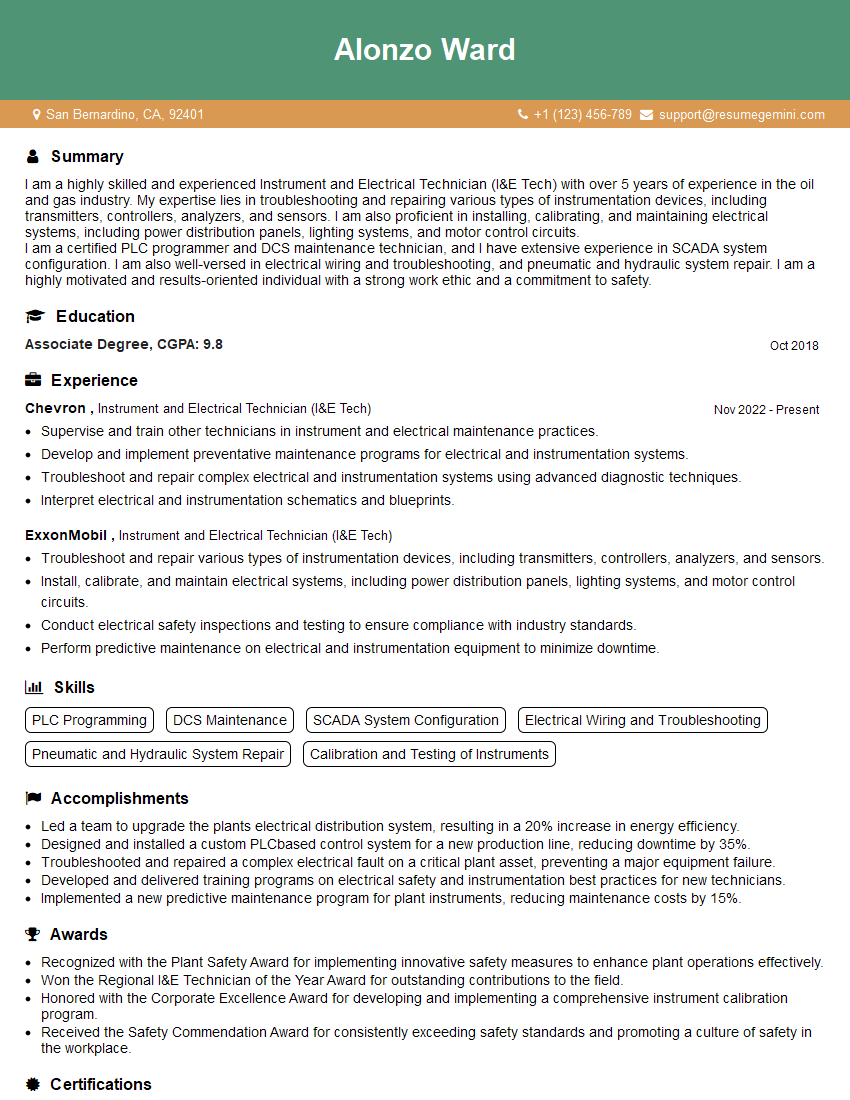

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument and Electrical Technician (I&E Tech)

1. Explain the working principle of a 3-phase induction motor.

A 3-phase induction motor operates on the principle of electromagnetic induction. When a 3-phase AC power supply is applied to the stator windings, it creates a rotating magnetic field. This rotating magnetic field induces an electromotive force (EMF) in the rotor conductors, which in turn creates a current in the rotor windings. The interaction between the rotating magnetic field and the current-carrying rotor conductors produces a torque that causes the rotor to rotate in the same direction as the magnetic field.

2. Describe the different types of electrical protection devices used in industrial settings and their purposes.

Fuses

- Fuses are overcurrent protection devices that interrupt the flow of current when it exceeds a predetermined value.

- They are typically used to protect electrical equipment from damage due to overloads or short circuits.

Circuit breakers

- Circuit breakers are also overcurrent protection devices, but they can be reset after they have tripped.

- They are typically used to protect electrical circuits from damage due to overloads or short circuits.

Ground fault circuit interrupters (GFCIs)

- GFCIs are designed to protect people from electrical shock by interrupting the flow of current when it detects a difference between the current flowing in the hot and neutral conductors.

- They are typically used in areas where there is a risk of electrical shock, such as bathrooms, kitchens, and outdoor areas.

3. Explain the purpose and operation of a transformer.

A transformer is an electrical device that transfers electrical energy from one circuit to another through electromagnetic induction. It consists of two or more coils of wire wound around a core of magnetic material. When an alternating current is applied to the primary winding, it creates a magnetic field in the core. This magnetic field then induces an alternating current in the secondary winding.

- Transformers can be used to step up or step down voltage, as well as to isolate circuits from each other.

4. Describe the different types of sensors used in instrumentation and their applications.

- Temperature sensors: Used to measure temperature, such as thermocouples, resistance temperature detectors (RTDs), and thermistors.

- Pressure sensors: Used to measure pressure, such as strain gauges, piezoelectric sensors, and capacitive sensors.

- Flow sensors: Used to measure the flow rate of a fluid, such as orifice plates, venturi tubes, and electromagnetic flow meters.

- Level sensors: Used to measure the level of a liquid or solid, such as ultrasonic sensors, capacitance sensors, and float switches.

5. Explain the difference between analog and digital signals.

- Analog signals are continuous signals that can take on any value within a range.

- Digital signals are discrete signals that can only take on specific values.

6. Describe the different types of electrical test equipment and their uses.

- Multimeters: Used to measure voltage, current, and resistance.

- Oscilloscopes: Used to display waveforms.

- Insulation testers: Used to measure the insulation resistance of electrical equipment.

- Megohmmeters: Used to measure the resistance of insulation.

7. Explain the importance of proper grounding in electrical systems.

Proper grounding in electrical systems is important for safety and to prevent damage to equipment.

- Grounding provides a low-resistance path for electrical current to flow in the event of a fault.

- This prevents the buildup of dangerous voltages on equipment and structures.

- Grounding also helps to protect against electrical shock.

8. Describe the different types of electrical wiring methods.

- Conduit: A metal or plastic pipe that protects electrical wires from damage.

- Cable tray: A metal or plastic trough that supports and protects electrical cables.

- Raceway: A channel or enclosure that houses electrical wires and cables.

- Open wiring: Electrical wires and cables that are run without any conduit, cable tray, or raceway.

9. Explain the purpose and operation of a programmable logic controller (PLC).

A PLC is a digital computer used to control industrial processes. It is programmed with a set of instructions that specify the desired operation of the process.

- PLCs are used in a wide variety of applications, such as manufacturing, transportation, and energy production.

10. Describe the different types of industrial automation systems.

- Supervisory control and data acquisition (SCADA) systems: Used to monitor and control industrial processes from a central location.

- Distributed control systems (DCSs): Used to control complex industrial processes from multiple locations.

- Programmable automation controllers (PACs): Used to control small to medium-sized industrial processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument and Electrical Technician (I&E Tech).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument and Electrical Technician (I&E Tech)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Instrument and Electrical Technicians (I&E Techs) are vital members of various industries, including manufacturing, power generation, and oil and gas. They are responsible for maintaining, troubleshooting, and repairing electrical and instrumentation systems, ensuring their optimal performance and safety. Key responsibilities of an I&E Tech include:

1. Electrical Maintenance and Repair

Installing, maintaining, and repairing electrical systems, including wiring, transformers, and circuit breakers.

- Inspecting electrical equipment and systems for potential hazards and defects

- Diagnosing and troubleshooting electrical faults using testing equipment and schematics

2. Instrumentation Maintenance and Repair

Maintaining, calibrating, and repairing instruments and devices used in measuring and controlling physical variables, such as temperature, pressure, and flow.

- Installing and configuring instrumentation systems and devices

- Performing routine inspections and calibrations to ensure accuracy and reliability

3. System Troubleshooting and Diagnostics

Analyzing system performance, identifying problems, and implementing solutions to optimize equipment and process functionality.

- Using analytical and diagnostic tools to pinpoint issues in complex systems

- Developing and executing maintenance and repair plans to mitigate downtime

4. Documentation and Record Keeping

Preparing technical reports, maintenance logs, and other documentation to ensure proper communication and traceability.

- Documenting repairs, calibrations, and maintenance activities

- Maintaining accurate records for compliance and troubleshooting purposes

Interview Tips

Preparing thoroughly for an interview is essential for showcasing your skills and qualifications as an I&E Tech. Here are some tips to help you ace the interview:

1. Research the Company and Position

Show that you took the time to learn about the company and understand the specific requirements of the role. Visit the company’s website, review their social media pages, and read any relevant articles to gain insights into their culture and business.

- Tailor your resume and cover letter to highlight skills and experiences that align with the job description

- Prepare questions for the interviewer that demonstrate your knowledge and interest in the company

2. Highlight Your Skills and Experience

Quantify your accomplishments by providing specific examples of your work experience. Use the STAR method (Situation, Task, Action, Result) to describe your involvement in projects and how your contributions impacted the organization.

- Provide examples of successful electrical or instrumentation projects you have worked on

- Showcase your troubleshooting and diagnostic abilities by giving instances where you identified and resolved complex issues

3. Demonstrate Your Problem-Solving Abilities

Interviewers are interested in candidates who can think critically and solve problems effectively. Prepare for questions that assess your analytical and decision-making skills. Practice solving hypothetical scenarios that relate to typical challenges faced by I&E Techs.

- Discuss how you approach problem-solving, emphasizing your logical reasoning and attention to detail

- Provide examples of situations where you used your problem-solving abilities to resolve technical issues

4. Emphasize Your Safety Awareness

Safety is paramount in the I&E field. Highlight your understanding of safety regulations and best practices. Describe your experience with implementing safety measures and adhering to industry standards.

- Discuss your knowledge of electrical safety codes and regulations

- Explain how you ensure safety during electrical and instrumentation maintenance and repair

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Instrument and Electrical Technician (I&E Tech) role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.