Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Instrument and Valve Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

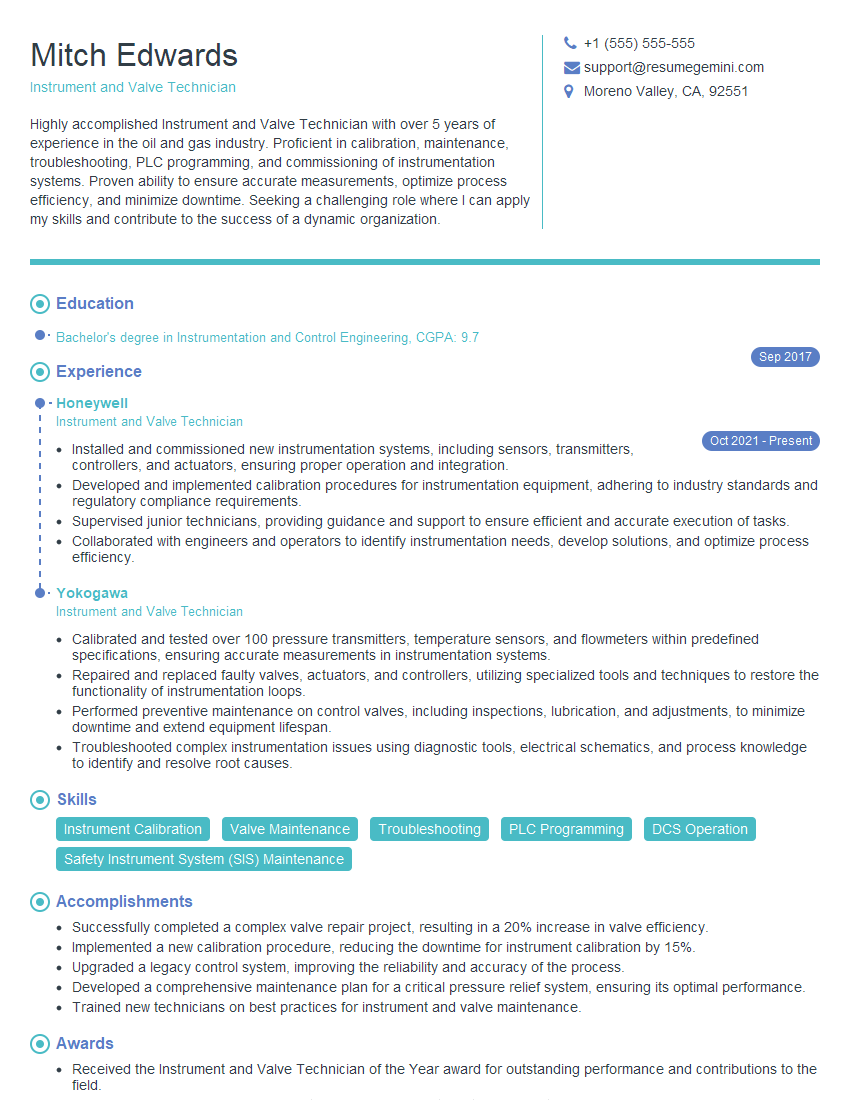

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument and Valve Technician

1. Explain the role of a diaphragm in a control valve?

– Primary element that senses the change in process variable – It converts the pneumatic signal into mechanical movement – Regulates the flow of fluid by changing the valve’s position

2. What are the different types of control valve actuators and their applications?

Pneumatic Actuators

- Diaphragm actuator: high precision, low force

- Piston actuator: high force, suitable for large valves

Electric Actuators

- Linear actuator: direct motion, high speed

- Rotary actuator: rotating motion, high torque

Hydraulic Actuators

- High force, high speed, suitable for heavy-duty applications

3. How do you troubleshoot a faulty pressure gauge?

- Check for physical damage, leaks, or blockages

- Verify power supply and connections

- Calibrate the gauge using a known pressure source

- Inspect the sensing element for proper function

4. Describe the process of calibrating a flowmeter?

- Use a certified flow source and reference standard

- Compare the flowmeter’s reading to the reference

- Adjust the flowmeter’s calibration screw or software

- Verify accuracy across the flowmeter’s range

5. What is the purpose of a pressure relief valve and how does it work?

– Protects the system from excessive pressure – Opens at a predetermined pressure, releasing excess fluid – Types: spring-loaded, pilot-operated, bursting disc

6. Explain the difference between a manual and an automatic control valve?

- Manual valve: requires manual operation to adjust the flow

- Automatic valve: responds to a process signal (e.g., pressure, temperature) to regulate the flow

7. What is the role of a positioner in a control valve system?

- Enhances the valve’s control accuracy and stability

- Converts the pneumatic signal from the controller into a precise valve position

- Compensates for friction and other non-linearities in the valve

8. Describe the different types of valve packing materials and their applications?

- Teflon: chemical compatibility, low friction

- Graphite: high-temperature resistance, sealing under vacuum

- Metallics: high pressure and temperature applications

- Elastomers: resilience, sealing against dirt and solids

9. What safety precautions should be taken when working with pressurized systems?

- Wear appropriate PPE (safety glasses, gloves)

- Identify and isolate hazardous areas

- Slowly release pressure before disassembly

- Follow established lockout/tagout procedures

10. Discuss the importance of proper instrument and valve maintenance in a process plant?

- Ensures reliable operation and accurate measurements

- Reduces downtime and production losses

- Improves safety and compliance

- Extends the lifespan of equipment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument and Valve Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument and Valve Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Instrument and Valve Technicians are responsible for the installation, maintenance, and repair of instruments, valves, and other equipment in a variety of industrial settings.

1. Installation

Install new instruments and valves according to specifications.

- Read and interpret blueprints and schematics.

- Assemble and install instruments and valves.

2. Maintenance

Perform preventive maintenance on instruments and valves to ensure proper operation.

- Inspect instruments and valves for wear and tear.

- Lubricate and adjust instruments and valves.

3. Repair

Repair or replace damaged instruments and valves.

- Troubleshoot problems with instruments and valves.

- Repair or replace damaged parts.

4. Calibration

Calibrate instruments and valves to ensure accuracy.

- Use calibration equipment to calibrate instruments and valves.

- Document calibration results.

Interview Tips

To ace an interview for an Instrument and Valve Technician position, it is important to prepare by researching the company and the position, practicing your answers to common interview questions, and dressing professionally.

1. Research

Research the company and the position to learn about the company’s culture, values, and goals. This will help you to answer questions about the company and to show that you are interested in the position.

- Visit the company’s website.

- Read articles and news about the company.

- Talk to people who work at the company.

2. Practice

Practice your answers to common interview questions. This will help you to feel more confident and prepared during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Dress professionally

Dress professionally for the interview. This will show the interviewer that you are serious about the position and that you are respectful of the company.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Wear comfortable shoes.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Instrument and Valve Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!