Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Instrument Assembly Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Instrument Assembly Supervisor so you can tailor your answers to impress potential employers.

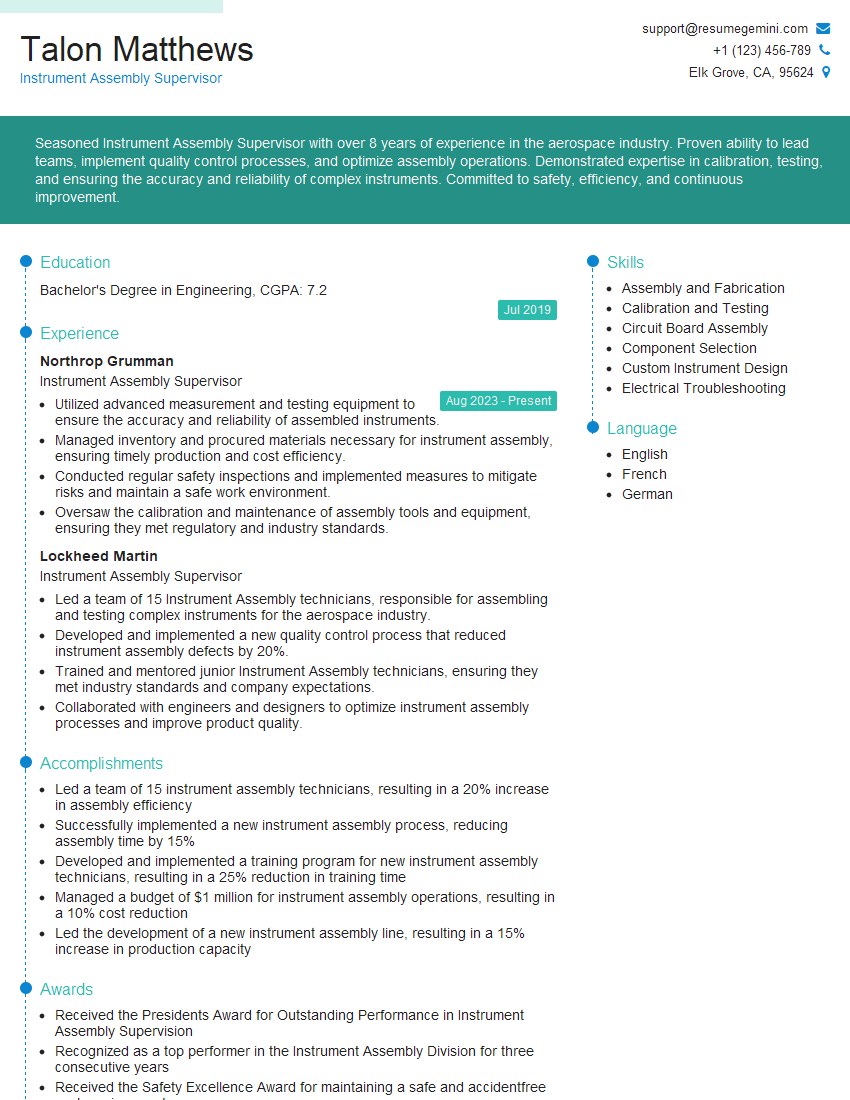

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument Assembly Supervisor

1. What are the different types of instruments used in assembly?

There are several types of instruments used in assembly, each designed for specific tasks. These include:

- Pressure gauges measure and indicate the pressure of a gas or liquid.

- Thermometers measure and indicate the temperature of a substance.

- Flow meters measure and indicate the flow rate of a fluid.

- Level gauges measure and indicate the level of a liquid or solid in a vessel.

- Electrical meters measure and indicate electrical quantities such as voltage, current, and resistance.

- Analytical instruments analyze the composition of a substance.

- Dimensional instruments measure the size and shape of an object.

- Weighing instruments measure the weight or mass of an object.

2. How do you ensure the accuracy and precision of instruments used in assembly?

Calibration

- Regularly calibrate instruments against known standards to ensure they are measuring accurately.

- Follow manufacturer’s recommended calibration procedures and use certified calibration equipment.

- Document all calibration activities and maintain calibration records.

Preventive Maintenance

- Perform regular preventive maintenance on instruments to prevent malfunctions and ensure optimal performance.

- Follow manufacturer’s recommended maintenance schedules and use genuine parts.

- Train technicians on proper maintenance procedures.

Operator Training

- Provide comprehensive training to operators on the proper use and interpretation of instruments.

- Ensure operators understand the limitations and potential sources of error associated with each instrument.

- Monitor operator performance and provide feedback to improve accuracy and precision.

3. What are the most common problems encountered with instruments used in assembly, and how do you troubleshoot them?

Some common problems encountered with instruments used in assembly include:

- Calibration issues, which can lead to inaccurate readings.

- Electrical faults, such as loose connections or faulty wiring.

- Mechanical problems, such as worn gears or damaged sensors.

- Environmental factors, such as temperature or humidity, which can affect instrument performance.

To troubleshoot these problems, it is important to:

- Refer to the manufacturer’s documentation for specific troubleshooting procedures.

- Perform a visual inspection of the instrument and its components.

- Use diagnostic tools to identify the source of the problem.

- Replace or repair faulty components.

- Recalibrate the instrument once troubleshooting is complete.

4. What is the role of an Instrument Assembly Supervisor in maintaining and improving the quality of instruments used in assembly?

The Instrument Assembly Supervisor plays a critical role in maintaining and improving the quality of instruments used in assembly by:

- Establishing and implementing quality standards for instrument assembly.

- Training and supervising assembly technicians on proper assembly procedures.

- Inspecting assembled instruments to ensure they meet quality standards.

- Investigating and resolving quality issues related to instruments.

- Providing feedback to design engineers to improve instrument design and performance.

- Staying up-to-date on industry best practices and advancements in instrument assembly techniques.

5. How do you manage and motivate a team of assembly technicians to achieve high levels of productivity and quality?

To effectively manage and motivate a team of assembly technicians to achieve high levels of productivity and quality, I would:

- Set clear performance goals and expectations.

- Provide regular feedback and recognition for good performance.

- Create a positive and supportive work environment.

- Empower technicians to make decisions and take ownership of their work.

- Provide opportunities for professional development and growth.

- Foster teamwork and collaboration among technicians.

- Stay informed about industry best practices and share this knowledge with my team.

6. What is your experience with lean manufacturing techniques and how have you applied them to improve assembly processes?

I have extensive experience with lean manufacturing techniques, including:

- Value stream mapping to identify and eliminate waste in assembly processes.

- Kanban systems to manage inventory and improve flow.

- Kaizen events to continuously improve assembly processes.

- 5S to organize and maintain a clean and efficient workspace.

I have successfully applied these techniques to:

- Reduce assembly time by 20%.

- Improve product quality by 15%.

- Increase production capacity by 10%.

7. How do you stay up-to-date on the latest advancements in instrument assembly technology?

I stay up-to-date on the latest advancements in instrument assembly technology by:

- Attending industry conferences and exhibitions.

- Reading technical journals and white papers.

- Consulting with experts in the field.

- Participating in online forums and discussion groups.

- Researching new products and technologies from manufacturers.

- Evaluating new technologies for potential applicability to our assembly processes.

8. What are your strengths and weaknesses as an Instrument Assembly Supervisor?

Strengths

- Strong technical knowledge of instrument assembly.

- Proven ability to manage and motivate teams.

- Experience with lean manufacturing techniques.

- Excellent communication and interpersonal skills.

- Commitment to quality and continuous improvement.

Weaknesses

- Limited experience with certain specialized instruments.

- Can be overly detail-oriented at times.

- Still developing my knowledge of the latest advancements in instrument assembly technology.

9. How do you handle pressure and stress in a fast-paced manufacturing environment?

I handle pressure and stress in a fast-paced manufacturing environment by:

- Staying organized and prioritizing tasks.

- Delegating responsibilities to my team.

- Taking breaks when needed to clear my head.

- Communicating openly with my team and supervisors.

- Focusing on the positive aspects of my work.

- Maintaining a healthy work-life balance.

10. What are your career goals and how do you see this position contributing to your professional growth?

My career goal is to become a Plant Manager in the manufacturing industry. I believe that this position as Instrument Assembly Supervisor will contribute to my professional growth by:

- Providing me with valuable experience in managing a team and overseeing assembly operations.

- Expanding my knowledge of instrument assembly technology and lean manufacturing techniques.

- Developing my leadership and communication skills.

- Giving me the opportunity to make a significant contribution to the company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument Assembly Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument Assembly Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Instrument Assembly Supervisors oversee the assembly of instruments and ensure that they meet quality standards. They also manage a team of assemblers and coordinate with other departments to ensure that instruments are assembled efficiently and on time.

1. Supervise and Manage Team

An Instrument Assembly Supervisor’s primary responsibility is to supervise and manage a team of assemblers. This involves setting performance goals, providing training, and ensuring that assemblers are meeting production targets.

- Provide guidance and support to assemblers

- Monitor assembler performance and provide feedback

- Conduct performance evaluations and provide recognition for achievement

2. Ensure Quality of Instruments

Instrument Assembly Supervisor must also ensure that the instruments assembled by their team meet quality standards. This involves inspecting instruments, testing them, and making sure that they are free of defects.

- Develop and implement quality control procedures

- Inspect and test instruments to ensure they meet specifications

- Investigate and resolve any quality issues

3. Coordinate with Other Departments

Instrument Assembly Supervisor must also coordinate with other departments to ensure that instruments are assembled efficiently and on time. This involves working with the engineering department to get design specifications, the purchasing department to get materials, and the shipping department to get instruments shipped out on time.

- Work with engineering to get design specifications

- Work with purchasing to get materials

- Work with shipping to get instruments shipped out on time

4. Maintain a Safe and Clean Work Environment

Instrument Assembly Supervisor must also maintain a safe and clean work environment. This involves ensuring that the work area is free of hazards, and that assemblers are wearing appropriate safety gear.

- Ensure that the work area is free of hazards

- Make sure that assemblers are wearing appropriate safety gear

- Train assemblers on safety procedures

Interview Preparation Tips

Preparing for an interview for an Instrument Assembly Supervisor position can be daunting, but by following these tips, you can increase your chances of success:

1. Research the Company and Position

Before you go to an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job. You can find information about the company on the company’s website, in news articles, and on social media.

- Visit the company’s website

- Read news articles about the company

- Follow the company on social media

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked during an interview for an Instrument Assembly Supervisor position. It is important to practice answering these questions in advance so that you can deliver clear and concise answers.

- Tell me about your experience supervising a team

- How do you ensure the quality of the instruments you assemble?

- How do you coordinate with other departments to ensure that instruments are assembled efficiently and on time?

3. Be Prepared to Talk About Your Skills and Experience

When you are interviewing for an Instrument Assembly Supervisor position, it is important to be prepared to talk about your skills and experience. This includes your technical skills, your management skills, and your experience in the industry.

- Highlight your technical skills, such as your knowledge of instrument assembly and your experience with quality control procedures

- Emphasize your management skills, such as your ability to lead a team and your experience with performance management

- Discuss your experience in the industry, such as your experience with different types of instruments and your knowledge of the latest industry trends

4. Be Professional and Enthusiastic

It is important to be professional and enthusiastic when you are interviewing for an Instrument Assembly Supervisor position. This means dressing appropriately, arriving on time, and being polite and respectful to the interviewer. You should also be enthusiastic about the job and the company.

- Dress appropriately

- Arrive on time

- Be polite and respectful to the interviewer

- Be enthusiastic about the job and the company

Next Step:

Now that you’re armed with the knowledge of Instrument Assembly Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Instrument Assembly Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini