Are you gearing up for a career in Instrument Installer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Instrument Installer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument Installer

1. What are the different types of sensors used in instrumentation?

There are various types of sensors used in instrumentation, including:

- Temperature sensors: Thermocouples, resistance temperature detectors (RTDs), and thermistors measure temperature.

- Pressure sensors: Pressure transducers, strain gauges, and bellows measure pressure.

- Flow sensors: Venturi tubes, orifice plates, and turbine flowmeters measure fluid flow.

- Level sensors: Level transmitters, ultrasonic sensors, and capacitance probes measure fluid level.

- Analytical sensors: pH probes, conductivity sensors, and gas sensors measure various chemical properties.

2. Describe the process of calibrating an instrument.

Zero calibration

- Remove any input signal to the instrument.

- Adjust the zero adjustment screw until the instrument output is zero.

Span calibration

- Apply a known input signal to the instrument.

- Adjust the span adjustment screw until the instrument output matches the known input signal.

3. Explain the difference between analog and digital signals.

- Analog signals: Analog signals are continuous signals that represent a physical quantity in proportion to its amplitude. They can take on any value within a given range.

- Digital signals: Digital signals are discrete signals that represent a physical quantity using a code or series of binary digits. They can only take on specific values.

4. What are the common communication protocols used in instrumentation?

- HART (Highway Addressable Remote Transducer): A widely used industrial protocol for communicating with field devices.

- Modbus: A versatile protocol used for communication between various devices in automation systems.

- PROFIBUS: A high-speed fieldbus protocol commonly used in process automation.

- Foundation Fieldbus: An open protocol specifically designed for process control applications.

- WirelessHART: A wireless version of the HART protocol for communication in hazardous areas.

5. What are the safety considerations to be aware of when working with instrumentation systems?

- Electrical hazards: Ensure proper grounding and follow lockout/tagout procedures.

- Pressure hazards: Verify system pressure ratings and use personal protective equipment (PPE) when working with high-pressure systems.

- Chemical hazards: Be aware of the chemicals being handled and wear appropriate PPE.

- Explosion hazards: Follow proper procedures when working in hazardous areas.

- Calibration safety: Calibrate instruments according to manufacturer’s instructions and use appropriate calibration equipment.

6. What are the different types of tubing used in instrumentation?

- Copper tubing: Used for pneumatic and hydraulic systems due to its flexibility and corrosion resistance.

- Stainless steel tubing: Used for higher-pressure applications and in corrosive environments.

- Nylon tubing: Used for low-pressure air and fluid applications due to its flexibility and chemical resistance.

- Polyethylene tubing: Used for low-pressure fluid applications due to its flexibility and low cost.

- Teflon tubing: Used for high-temperature and high-pressure applications due to its chemical inertness and thermal stability.

7. How do you troubleshoot a faulty instrument?

- Gather information: Note the instrument’s symptoms, operating conditions, and any recent changes.

- Check the power supply: Ensure the instrument is receiving power and that the voltage and current are within specifications.

- Inspect the wiring: Check for loose connections, damaged wires, or shorts.

- Calibrate the instrument: Verify if the instrument is properly calibrated and make adjustments if necessary.

- Replace faulty components: If necessary, replace any damaged or failed components.

8. What are the typical responsibilities of an Instrument Installer?

- Install, maintain, and repair instrumentation systems.

- Calibrate and configure instruments according to specifications.

- Troubleshoot and diagnose instrument malfunctions.

- Document and report on instrumentation system performance.

- Follow safety protocols and adhere to industry standards.

9. What are some of the challenges you have faced as an Instrument Installer?

Some challenges I have faced as an Instrument Installer include:

- Working in hazardous environments with high-pressure systems and electrical hazards.

- Troubleshooting complex instrumentation systems and identifying the root cause of failures.

- Meeting tight deadlines while ensuring accuracy and quality in my work.

- Staying up-to-date with advancements in instrumentation technology and industry best practices.

- Collaborating effectively with other trades and engineers on multidisciplinary projects.

10. What are your strengths and weaknesses as an Instrument Installer?

Strengths

- Strong technical skills in instrumentation and electrical systems.

- Excellent troubleshooting and problem-solving abilities.

- Meticulous attention to detail and a commitment to accuracy.

- Ability to work independently and as part of a team.

- Certified in instrumentation and safety protocols.

Weaknesses

- I sometimes struggle to meet tight deadlines under pressure.

- I am relatively new to the industry and still learning about the latest advancements.

- I can be overly critical of my own work and may spend too much time on details.

- I am not yet familiar with all of the specific codes and standards for instrumentation in this industry.

- I am eager to learn and improve, but I may need additional training and experience in certain areas.

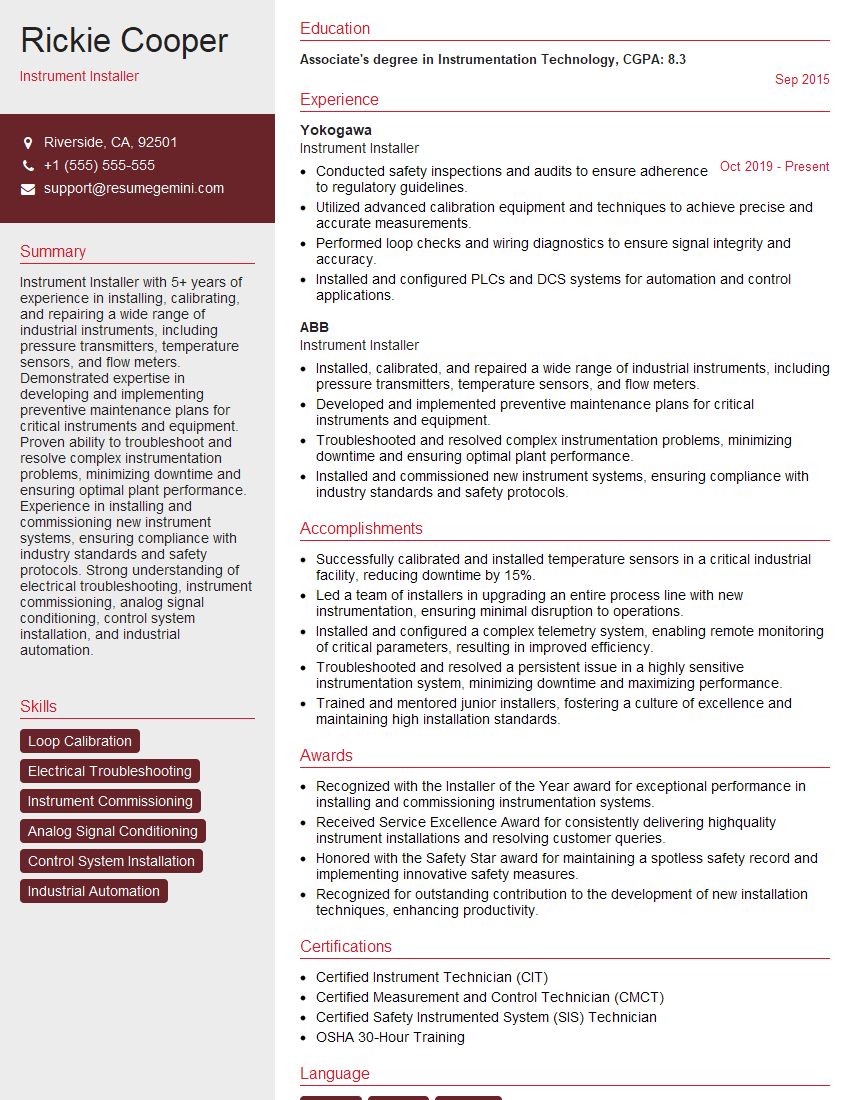

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Instrument Installer is responsible for the installation, maintenance, and repair of instruments and equipment used in various industries, including manufacturing, power generation, and healthcare.

1. Instrument Installation

The Instrument Installer is responsible for the installation of new instruments and equipment according to specifications and blueprints. This includes:

- Receiving and unpacking instruments and equipment

- Mounting and securing instruments and equipment

- Connecting instruments and equipment to electrical and other systems

- Calibrating and testing instruments and equipment to ensure proper operation

2. Instrument Maintenance

The Instrument Installer is responsible for the maintenance and repair of instruments and equipment to ensure their continued operation. This includes:

- Inspecting instruments and equipment for wear and tear

- Replacing worn or damaged parts

- Adjusting and calibrating instruments and equipment

- Troubleshooting and repairing instrumentation and equipment problems

- Maintaining records of maintenance and repairs

3. Troubleshooting and Repair

The Instrument Installer is responsible for troubleshooting and repairing instrumentation and equipment problems. This includes:

- Diagnosing the source of instrumentation and equipment problems

- Repairing or replacing faulty components

- Testing repaired instrumentation and equipment to ensure proper operation

- Documenting troubleshooting and repair activities

4. Safety Compliance

The Instrument Installer is responsible for ensuring that all work is performed in accordance with safety regulations and procedures. This includes:

- Wearing appropriate safety gear

- Following proper lockout/tagout procedures

- Working in a safe and responsible manner

- Maintaining a clean and organized work area

Interview Tips

Preparing for an interview can be daunting, but following these tips will help you increase your chances of success when interviewing for an Instrument Installer position. Here are some tips to help you ace your interview:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you’re applying for. This will help you understand the company’s culture, values, and what they’re looking for in a candidate.

2. Practice your answers to common interview questions

There are some common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Highlight your skills and experience

In your interview, be sure to highlight your skills and experience that are relevant to the position you’re applying for. For example, if you have experience installing and maintaining instruments in a manufacturing environment, be sure to mention that in your interview.

4. Dress professionally and be on time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows that you’re respectful of the interviewer’s time and that you’re taking the interview seriously.

5. Be enthusiastic and positive

A positive attitude can go a long way in an interview. Be enthusiastic about the position and the company, and be sure to convey that you’re excited about the opportunity to work there.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Instrument Installer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.