Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Instrument Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

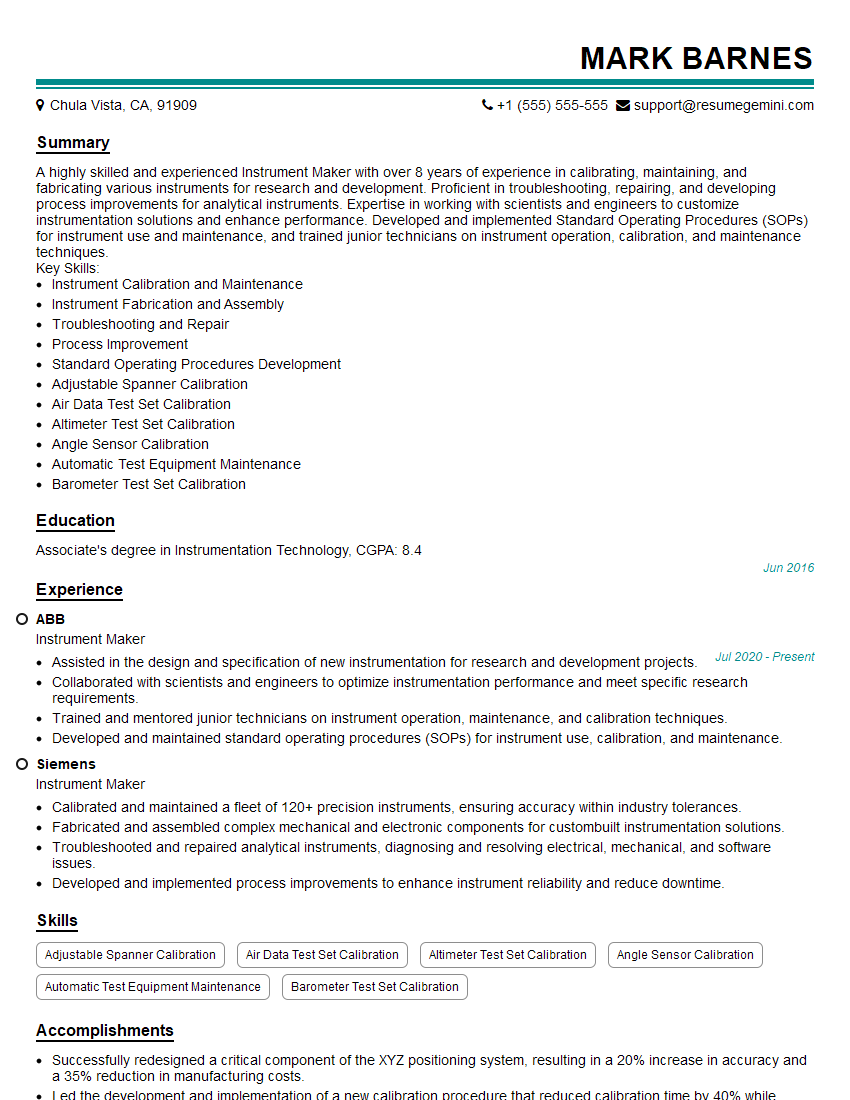

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument Maker

1. What are the different types of measuring instruments that you are familiar with, and what are their applications?

- Vernier caliper – Used to measure linear distances with a high degree of accuracy.

- Micrometer – Used to measure external and internal dimensions with a very high degree of accuracy.

- Dial indicator – Used to measure small movements of a surface or component.

- Clinometer – Used to measure the angle of inclination of a surface.

- Theodolite – Used to measure angles of elevation and azimuth.

- Digital multimeter – Used to measure electrical properties such as voltage, current, and resistance.

- Oscilloscope – Used to display waveforms and measure electrical properties.

- Laser level – Used to project a horizontal or vertical laser line to establish a level or plumb reference.

- Total station – A combination of a theodolite and an electronic distance meter, used for surveying and construction.

- Coordinate measuring machine (CMM) – A computer-controlled machine used to measure the dimensions and location of complex objects.

2. What are the different types of materials used in the construction of scientific instruments, and what are their properties?

Metals

- Steel – Strong, durable, and wear-resistant.

- Aluminium – Lightweight, strong, and corrosion-resistant.

- Brass – Corrosion-resistant and machinable.

- Copper – Conductive, ductile, and malleable.

Ceramics

- Glass – Transparen t, can be shaped and polished to precise dimensions.

- Quartz – Hard, durable, and chemically inert.

- Sapphire – Extremely hard and wear-resistant.

Polymers

- Polyethylene – Flexible, lightweight, and chemically resistant.

- Polypropylene – Strong, tough, and heat-resistant.

- Polycarbonate – Transparent, impact-resistant, and heat-resistant.

Composites

- Carbon fiber – Strong, lightweight, and stiff.

- Fiberglass – Strong, lightweight, and corrosion-resistant.

- Kevlar – Strong, lightweight, and impact-resistant.

3. Describe the process of calibrating a scientific instrument.

- Determine the source of the calibration – This could be a national or international standard, or a reference instrument that has been calibrated against a standard.

- Set up the instrument – This may involve leveling the instrument, adjusting the focus, or setting the zero point.

- Measure the known standard – This is typically done several times to ensure accurate measurements.

- Compare the measured values to the known values – This will identify any errors in the instrument’s readings.

- Adjust the instrument – If necessary, the instrument can be adjusted to bring its readings into line with the known values.

- Document the calibration – This should include the date of calibration, the source of the calibration, and any adjustments that were made.

4. Describe the operation of a Coordinate Measuring Machine (CMM).

- The CMM is a computer-controlled machine that is used to measure the dimensions and location of objects in three dimensions.

- The CMM uses a probe to touch the surface of the object at multiple points.

- The CMM then uses the data from the probe to create a digital model of the object.

- The digital model can then be used to inspect the object for errors, to create drawings, or to generate tool paths for manufacturing.

5. What are the different types of errors that can occur in scientific measurements, and what are the methods used to minimize these errors?

Types of errors

- Systematic errors – These are errors that are caused by a flaw in the measuring instrument or in the measurement process.

- Random errors – These are errors that are caused by random variations in the measurement process.

Methods to minimize errors

- Use a well-calibrated instrument

- Follow the proper measurement procedure

- Take multiple measurements and average the results

- Use statistical methods to identify and eliminate outliers

6. What are the ethical responsibilities of an instrument maker?

- To ensure that the instruments they make are accurate and reliable.

- To use their skills and knowledge responsibly.

- To protect the health and safety of themselves and others.

- To be honest and transparent in their work.

- To respect the intellectual property of others.

7. What are the future trends in instrument making?

- The use of new materials and technologies to create more accurate and reliable instruments.

- The development of new instruments to meet the needs of emerging fields of science and technology.

- The increasing use of automation in instrument making.

- The development of new standards and regulations for instrument making.

- The increasing importance of sustainability in instrument making.

8. How do you stay up-to-date on the latest developments in instrument making?

- Read technical journals and articles.

- Attend conferences and workshops.

- Visit trade shows.

- Network with other instrument makers.

- Take online courses.

9. What are your strengths and weaknesses as an instrument maker?

-

Strengths:

- Accuracy and precision

- Attention to detail

- Problem-solving skills

- Communication skills

- Teamwork skills Weaknesses:

- May not be familiar with all types of instruments

- May not be able to work independently

- May not be able to meet deadlines

10. Why are you interested in working for our company?

- I am interested in working for your company because I am impressed with your company’s commitment to quality and innovation.

- I believe that my skills and experience would be a valuable asset to your team.

- I am eager to learn more about your company and the products that you make.

- I am confident that I can make a significant contribution to your company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Instrument Makers are highly skilled professionals responsible for designing, building, modifying, testing, calibrating, repairing, and installing precision instruments and equipment used in various industries. Key job responsibilities include:

1. Design and Development

Collaborate with engineers and scientists to develop and design instruments and equipment

- Creating prototypes and conducting tests to ensure specifications are met

- Working with advanced software and computer-aided design (CAD) tools

2. Fabrication and Assembly

Use specialized tools and techniques to fabricate and assemble instruments

- Working with a variety of materials such as metal, plastic, and glass

- Ensuring precision and accuracy in fabrication and assembly

3. Testing and Calibration

Test and calibrate instruments to ensure they meet established standards

- Using specialized equipment and techniques for testing

- Adjusting and calibrating instruments to ensure optimal performance

4. Repairs and Maintenance

Troubleshoot, repair, and maintain instruments and equipment

- Identifying and resolving malfunctions

- Replacing worn or damaged parts

5. Quality Control

Ensure the quality of instruments and equipment through rigorous testing and inspection

- Adhering to industry standards and regulations

- Documenting quality control procedures

Interview Tips

To ace the interview, consider these tips:

1. Research the Company and Position

Thoroughly research the company, its industry, and the specific position you are applying for

- This shows that you are genuinely interested in the opportunity

- Use the company’s website, LinkedIn, and industry articles as sources

2. Practice Your Answers

Prepare and practice your answers to common interview questions

- Anticipate questions on your technical skills, experience, and motivations

- Use the job description as a guide

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements

- Use specific examples to demonstrate your abilities

- Quantify your accomplishments wherever possible

4. Prepare Questions to Ask

Prepare thoughtful questions to ask the interviewer

- This shows that you are engaged and interested

- Examples: About the company’s growth plans, specific projects you would be involved in

5. Follow Up After the Interview

Send a thank-you note to the interviewer within 24 hours

- Reiterate your interest in the position

- Address any points you may have missed during the interview

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Instrument Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.