Feeling lost in a sea of interview questions? Landed that dream interview for Instrument Man (I-Man) but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Instrument Man (I-Man) interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

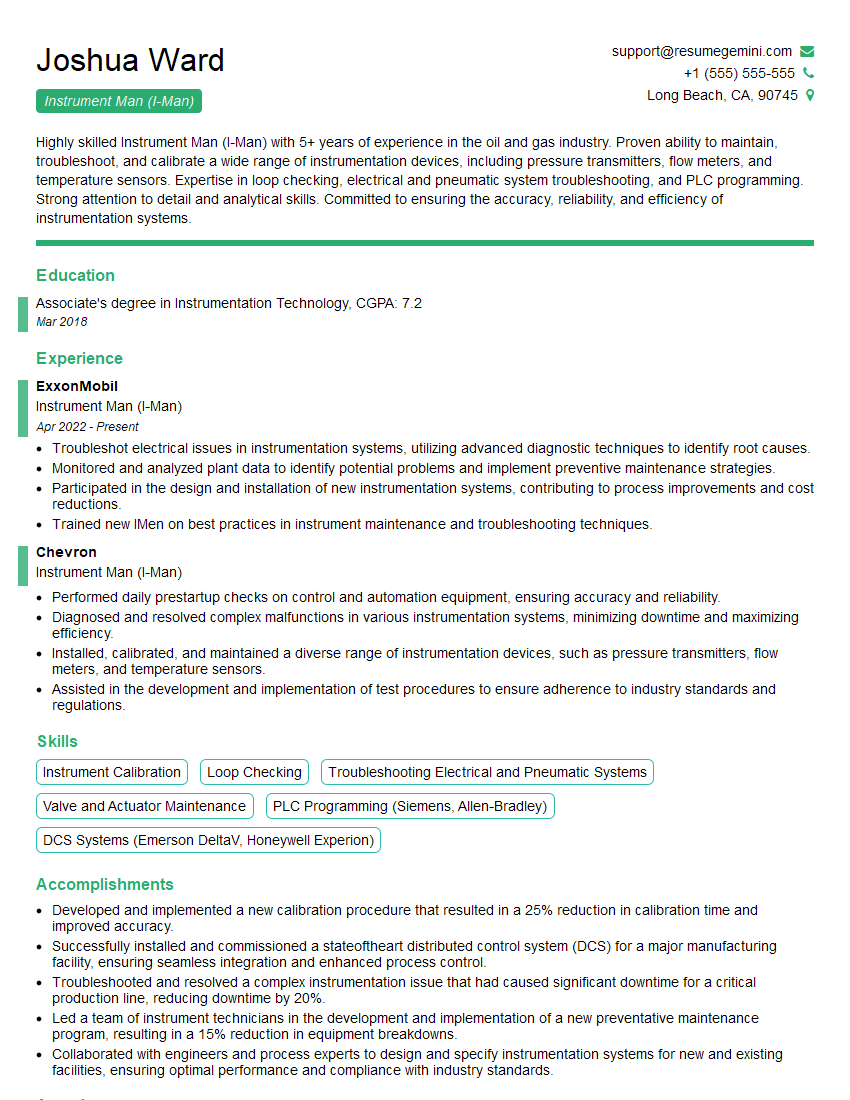

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument Man (I-Man)

1. What is the difference between accuracy and precision?

Accuracy refers to how close a measurement is to the true value, while precision refers to how consistent the measurements are with each other. A measurement can be accurate but not precise, or precise but not accurate.

- Accuracy is determined by the calibration of the instrument and the skill of the operator.

- Precision is determined by the repeatability of the instrument and the stability of the process being measured.

2. What are the different types of flowmeters?

Differential pressure flowmeters

- Venturi tube

- Orifice plate

- Flow nozzle

- Pitot tube

Velocity flowmeters

- Turbine flowmeter

- Magnetic flowmeter

- Ultrasonic flowmeter

- Vortex shedding flowmeter

Positive displacement flowmeters

- Oval gear flowmeter

- Diaphragm flowmeter

- Piston flowmeter

- Nutating disk flowmeter

3. What is the principle of operation of a magnetic flowmeter?

Magnetic flowmeters operate on the principle of electromagnetic induction. When a conducting fluid flows through a magnetic field, an electromotive force (EMF) is generated perpendicular to both the flow and the magnetic field. The magnitude of the EMF is proportional to the velocity of the fluid.

- Magnetic flowmeters are non-invasive and do not require any contact with the fluid being measured.

- They are also immune to changes in fluid density, viscosity, and temperature.

4. What is the difference between a two-wire and a four-wire RTD?

A two-wire RTD has two wires that connect to the sensor, while a four-wire RTD has four wires that connect to the sensor. The two extra wires in a four-wire RTD are used to compensate for the resistance of the lead wires.

- Two-wire RTDs are less expensive and easier to install than four-wire RTDs.

- Four-wire RTDs are more accurate than two-wire RTDs because they compensate for the resistance of the lead wires.

5. What are the different types of thermocouples?

- Type J (iron-constantan)

- Type K (chromel-alumel)

- Type T (copper-constantan)

- Type E (chromel-constantan)

- Type N (nicrosil-nisil)

- Type S (platinum-rhodium)

6. What is the principle of operation of a strain gauge?

Strain gauges operate on the principle of piezoresistivity. When a strain gauge is subjected to a strain, its electrical resistance changes. The magnitude of the resistance change is proportional to the strain.

- Strain gauges are used to measure strain in a variety of materials, including metals, plastics, and composites.

- They are also used to measure pressure, force, and torque.

7. What is the difference between a transducer and a transmitter?

A transducer converts one form of energy into another form of energy. A transmitter is a type of transducer that converts a physical quantity into an electrical signal.

- Transducers are used in a wide variety of applications, including instrumentation, control systems, and medical devices.

- Transmitters are often used to send the electrical signal from the transducer to a remote location.

8. What are the different types of control valves?

- Globe valves

- Gate valves

- Butterfly valves

- Diaphragm valves

- Ball valves

- Check valves

9. What is the difference between a proportional-integral-derivative (PID) controller and a proportional-integral (PI) controller?

A PID controller is a type of feedback controller that uses three feedback terms: proportional, integral, and derivative. A PI controller is a type of feedback controller that uses only two feedback terms: proportional and integral.

- PID controllers are more complex to tune than PI controllers.

- PID controllers can provide better performance than PI controllers in certain applications.

10. What are the different types of data acquisition systems?

- Analog data acquisition systems

- Digital data acquisition systems

- Mixed-signal data acquisition systems

11. What is the difference between a data logger and a supervisory control and data acquisition (SCADA) system?

A data logger is a device that records data from sensors and stores it for later retrieval. A SCADA system is a computer-based system that collects data from sensors, monitors the data, and controls the process being monitored.

- Data loggers are typically used for standalone applications.

- SCADA systems are typically used for large-scale applications.

12. What are the different types of communication protocols used in industrial automation?

- Modbus

- Profibus

- DeviceNet

- ControlNet

- Ethernet/IP

- HART

- Foundation Fieldbus

13. What are the different types of safety instrumented systems (SIS)?

- Basic safety instrumented systems (BSIS)

- Safety instrumented systems (SIS)

- High-integrity safety instrumented systems (HISIS)

14. What are the different types of programmable logic controllers (PLCs)?

- Compact PLCs

- Modular PLCs

- Rack-based PLCs

- Distributed PLCs

15. What are the different types of human-machine interfaces (HMIs)?

- Text-based HMIs

- Graphical HMIs

- Web-based HMIs

- Mobile HMIs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument Man (I-Man).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument Man (I-Man)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Instrument Man (I-Man) plays a pivotal role in ensuring the accuracy and precision of instruments and equipment used in various industries, including manufacturing, construction, and scientific research. Their primary responsibilities encompass:

1. Calibration and Maintenance

I-Mans are responsible for calibrating and maintaining a wide range of instruments, including gauges, meters, sensors, and measuring devices. This involves adjusting and fine-tuning these instruments to achieve optimal performance and accuracy.

- Performing routine inspections and calibrations to ensure accuracy and compliance with industry standards.

- Troubleshooting and repairing instruments to identify and resolve malfunctions.

2. Instrument Selection and Installation

I-Mans collaborate with engineers and technicians to select the appropriate instruments for specific applications and oversee their installation. They ensure that the instruments are properly mounted, connected, and calibrated to meet the project requirements.

- Assessing the measurement needs of a project and recommending suitable instruments.

- Installing and configuring instruments according to defined specifications and procedures.

3. Data Collection and Analysis

I-Mans collect and analyze data from various instruments to monitor and evaluate system performance. They identify trends, anomalies, and potential issues, providing valuable insights for decision-making.

- Gathering and interpreting data from sensors, recorders, and other instruments.

- Analyzing data to identify performance trends and potential problems.

4. Documentation and Reporting

I-Mans maintain detailed records of instrument calibrations, maintenance activities, and data collected. They prepare reports and documentation to communicate findings and recommendations to stakeholders.

- Documenting calibration procedures, maintenance logs, and troubleshooting records.

- Preparing reports on instrument performance, data analysis, and recommendations.

Interview Tips

To ace an interview for an Instrument Man position, candidates should prepare thoroughly and showcase their technical expertise, problem-solving skills, and attention to detail. Here are some key tips and interview preparation hacks:

1. Research the Company and Position

Before the interview, thoroughly research the company, its industry, and the specific role you are applying for. This knowledge will demonstrate your interest and help you tailor your answers to the interviewer’s questions.

- Visit the company website to learn about their products, services, and culture.

- Read industry news and articles to stay updated on the latest trends and technologies.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your skills and experience. Practice with a friend or family member to gain confidence and improve your delivery.

- Describe your experience in calibrating and maintaining instruments.

- Explain how you troubleshoot and resolve instrument malfunctions.

3. Prepare Technical Questions

I-Man interviews often involve technical questions to assess your understanding of instrument principles and applications. Be prepared to discuss topics such as:

- Different types of measurement instruments and their applications.

- Calibration techniques and standards.

- Data acquisition and analysis methods.

4. Showcase Your Problem-Solving Skills

Interviewers value candidates who can demonstrate their ability to solve problems effectively. Prepare examples from your past experience where you identified and resolved instrument issues or improved measurement accuracy.

- Describe a situation where you diagnosed and fixed a complex instrument malfunction.

- Explain how you optimized an instrument setup to enhance data accuracy.

5. Be Enthusiastic and Professional

Showcasing your enthusiasm for the role and your commitment to maintaining accuracy and precision is essential. Dress professionally, maintain eye contact, and ask thoughtful questions to demonstrate your interest and engagement.

- Express your passion for ensuring instrument reliability and data integrity.

- Ask questions about the company’s measurement practices and industry challenges.

Next Step:

Now that you’re armed with the knowledge of Instrument Man (I-Man) interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Instrument Man (I-Man) positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini