Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Instrument Man position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

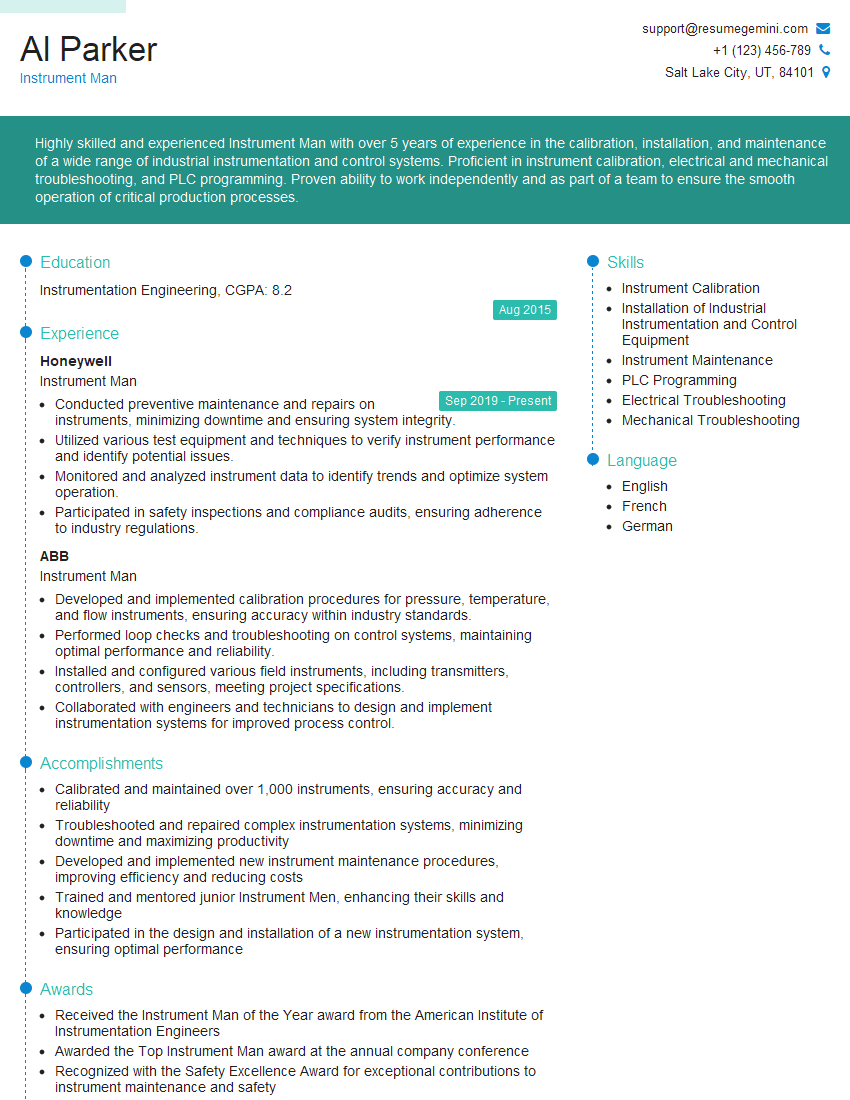

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument Man

1. Describe the process of calibrating a pressure transmitter?

Example Answer:

- Connect the pressure transmitter to a pressure calibrator or reference pressure source.

- Apply a known and stable pressure to the transmitter.

- Read the output signal from the transmitter.

- Compare the output signal to the expected value.

- Adjust the transmitter’s calibration if necessary to match the expected value.

2. Explain the principles of operation of a Coriolis flow meter?

Mass Flow Measurement

- Measures the mass flow directly, independent of fluid properties.

- Utilizes vibrating tubes and detects the Coriolis effect.

Density Measurement

- Can provide density measurements by analyzing the flow oscillations.

- Calculates density based on the changes in frequency and amplitude of the tubes.

3. How would you troubleshoot a temperature sensor that is reading incorrectly?

Example Answer:

- Inspect the sensor for physical damage or loose connections.

- Verify the calibration of the sensor using a known temperature source.

- Check the wiring and connections between the sensor and the indicator.

- Test the indicator to ensure it is functioning correctly.

- Replace the sensor if necessary.

4. Describe the different types of level measurement technologies and their applications?

Example Answer:

- Capacitance: Used for liquids, slurries, and granular solids.

- Ultrasonic: Non-contact measurement for various materials, including liquids, solids, and powder.

- Radar: Non-contact measurement for liquids, solids, and bulk materials in harsh conditions.

- Float Switch: Simple and cost-effective for high or low-level detection.

- Vibrating Fork: Precise and reliable for liquids with minimal vibration.

5. Explain the function of a DCS (Distributed Control System) in an industrial plant?

Example Answer:

- Controls and monitors various processes throughout the plant.

- Integrates data from sensors, actuators, and other instruments.

- Automates control loops to maintain desired process conditions.

- Provides a centralized platform for monitoring and managing the entire process.

- Allows remote access and control for optimal plant operation.

6. What is the difference between a safety instrumented system (SIS) and a basic process control system (BPCS)?

Example Answer:

- SIS: Designed to protect personnel, the environment, and plant assets in critical situations.

- BPCS: Focuses on maintaining process efficiency and product quality.

- SIS: Requires higher levels of reliability and redundancy.

- SIS: May have separate hardware and software systems.

- BPCS: Typically integrated with other plant systems.

7. Describe your experience with programmable logic controllers (PLCs).

Example Answer:

- Developed and implemented PLC programs for industrial automation systems.

- Used ladder logic, function blocks, and other programming languages.

- Designed and wired PLC I/O modules.

- Troubleshooted and maintained PLC systems.

- Experience with major PLC brands, such as Rockwell, Siemens, and Allen-Bradley.

8. How do you ensure the accuracy and reliability of your instrument maintenance practices?

Example Answer:

- Follow established maintenance procedures and standards.

- Use calibrated test equipment and tools.

- Document all maintenance activities and results.

- Receive ongoing training and certification.

- Participate in peer reviews and audits.

9. What steps do you take when troubleshooting a complex instrument issue?

Example Answer:

- Gather information about the issue and its history.

- Review documentation and schematics.

- Conduct physical inspections and tests.

- Use diagnostic tools and meters.

- Consult with colleagues and experts.

- Develop and implement a solution plan.

10. Describe your understanding of the latest trends and technologies in industrial instrumentation?

Example Answer:

- Wireless instrumentation for remote monitoring and data acquisition.

- IIoT (Industrial Internet of Things) and digital transformation.

- Advanced sensors with improved accuracy and sensitivity.

- Cloud-based data analysis and predictive maintenance.

- Virtual and augmented reality for training and troubleshooting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument Man.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument Man‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Instrument Man is a skilled professional responsible for the installation, maintenance, repair, and calibration of various instruments and equipment. Their duties encompass a wide range of tasks related to instrumentation in industrial, manufacturing, and scientific settings.

1. Installation and Commissioning

Install and commission new instruments and machinery ensuring they meet specifications and safety standards.

- Conduct site surveys, prepare equipment layouts, and determine instrument requirements.

- Install instruments, connect wiring, and perform initial setup and testing.

2. Troubleshooting and Maintenance

Identify and troubleshoot issues with instruments and control systems, ensuring efficient operation and minimizing downtime.

- Conduct regular inspections, perform preventive maintenance, and calibrate instruments.

- Diagnose instrument malfunctions, repair or replace faulty components, and restore functionality.

3. Calibration and Documentation

Calibrate instruments according to established standards and procedures, ensuring accuracy and reliability.

- Perform periodic calibration using certified equipment and traceable standards.

- Maintain calibration records and document all measurements, adjustments, and repairs.

4. Data Analysis and Reporting

Collect, analyze, and interpret instrument data to identify trends and patterns supporting operational improvements.

- Use data logging systems to collect and store instrument readings.

- Analyze data to identify performance issues, equipment failures, and potential improvements.

Interview Tips

Preparation is key to acing an interview for an Instrument Man position. Here are some tips that will help you stand out:

1. Research the Company and Role

Gather information about the company, its industry, and the specific requirements of the Instrument Man role.

- Visit the company website, read industry publications, and network with professionals in the field.

- Identify the key skills and experience required for the position and tailor your resume and interview answers accordingly.

2. Highlight Your Technical Expertise

Emphasize your knowledge and experience in instrument installation, maintenance, calibration, and troubleshooting.

- Provide specific examples of complex projects you have worked on, highlighting your analytical and problem-solving abilities.

- Mention any certifications or training you have obtained in the field, demonstrating your commitment to professional development.

3. Showcase Your Communication and Interpersonal Skills

Instrument Men often work independently but must also be able to communicate effectively with colleagues and clients.

- Describe situations where you effectively communicated technical information to non-technical personnel.

- Explain how you resolve conflicts and build productive relationships with team members.

4. Be Prepared to Answer Technical Questions

Anticipate questions about instrumentation principles, calibration techniques, and troubleshooting methodologies.

- Review common instrument types, measurement techniques, and industry standards.

- Practice answering questions about troubleshooting scenarios and technical problem-solving.

5. Prepare Questions for the Interviewer

Asking thoughtful questions shows your interest in the position and the company. Consider asking about:

- The company’s current instrumentation projects and future plans.

- The specific challenges and opportunities associated with the Instrument Man role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Instrument Man interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.