Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Instrument Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

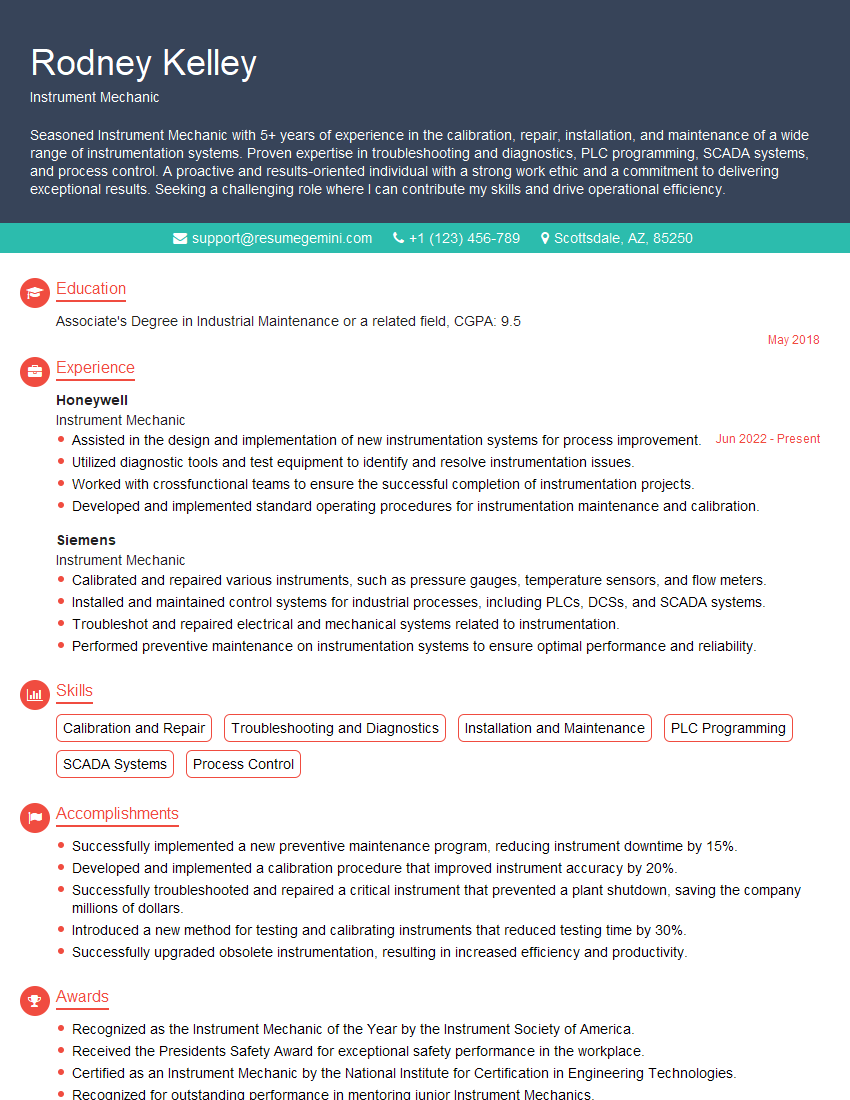

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument Mechanic

1. What are the different types of instruments that you have experience working with?

I have experience working with a wide variety of instruments, including:

- Pressure gauges

- Temperature gauges

- Flow meters

- Level gauges

- Analytical instruments

2. What are the different types of calibration procedures that you are familiar with?

Gravimetric calibration

- This involves using a known weight to calibrate a scale or balance.

- It is a very accurate method of calibration, but it can be time-consuming.

Volumetric calibration

- This involves using a known volume to calibrate a pipette or burette.

- It is a less accurate method of calibration than gravimetric calibration, but it is faster.

Electrical calibration

- This involves using a known electrical signal to calibrate an electrical instrument.

- It is a very accurate method of calibration, and it can be used to calibrate a wide variety of instruments.

3. What are the different types of maintenance procedures that you are familiar with?

I am familiar with a variety of maintenance procedures, including:

- Preventative maintenance

- Corrective maintenance

- Overhaul

- Calibration

4. What are the different types of troubleshooting procedures that you are familiar with?

I am familiar with a variety of troubleshooting procedures, including:

- Symptom-based troubleshooting

- Cause-based troubleshooting

- Logic-based troubleshooting

5. What are the different types of documentation that you are familiar with?

I am familiar with a variety of documentation, including:

- Maintenance manuals

- Calibration records

- Troubleshooting guides

- Work orders

- Safety manuals

6. What are the different types of safety procedures that you are familiar with?

I am familiar with a variety of safety procedures, including:

- Lockout/tagout procedures

- Electrical safety procedures

- Chemical safety procedures

- Fire safety procedures

- Ergonomic safety procedures

7. What are the different types of quality assurance procedures that you are familiar with?

I am familiar with a variety of quality assurance procedures, including:

- ISO 9001

- ASME B16.5

- ANSI/ISA-5.1

- API RP 550

8. What are the different types of software that you are familiar with?

I am familiar with a variety of software, including:

- Instrument calibration software

- Maintenance management software

- Troubleshooting software

- Documentation software

- Safety software

9. What are the different types of equipment that you are familiar with?

I am familiar with a variety of equipment, including:

- Pressure gauges

- Temperature gauges

- Flow meters

- Level gauges

- Analytical instruments

- Electrical instruments

- Mechanical instruments

10. What are the different types of industries that you have experience working in?

I have experience working in a variety of industries, including:

- Oil and gas industry

- Chemical industry

- Pharmaceutical industry

- Food and beverage industry

- Power generation industry

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Instrument Mechanics are responsible for maintaining and repairing a wide range of instruments, such as pressure gauges, flow meters, and temperature sensors. They work in various industries, including manufacturing, pharmaceuticals, and power plants.

1. Inspect and Repair Instruments

Instrument Mechanics inspect instruments to ensure they are functioning properly. They may also troubleshoot and repair faulty instruments, using hand tools and specialized equipment.

- Inspect instruments for wear and tear, corrosion, and other damage.

- Troubleshoot and repair faulty instruments using hand tools and specialized equipment.

- Replace parts, such as sensors, seals, and gaskets.

2. Calibrate and Test Instruments

Instrument Mechanics calibrate and test instruments to ensure they are accurate and reliable. They may use specialized equipment, such as calibrators and test benches.

- Calibrate instruments according to manufacturer’s specifications.

- Test instruments to ensure they meet accuracy and reliability standards.

- Adjust instruments as needed to achieve optimal performance.

3. Install and Maintain Instruments

Instrument Mechanics may also install and maintain instruments. They may work with engineers to determine the best location for instruments and ensure they are properly installed.

- Install instruments according to blueprints and specifications.

- Maintain instruments by cleaning, lubricating, and adjusting them as needed.

- Perform preventive maintenance to minimize downtime and ensure optimal performance.

4. Work with Other Professionals

Instrument Mechanics often work with other professionals, such as engineers, electricians, and millwrights. They may also work with customers to troubleshoot and repair instruments.

- Collaborate with engineers to determine instrument requirements.

- Work with electricians and millwrights to install and maintain instruments.

- Provide technical support to customers and troubleshoot instrument issues.

Interview Tips

Preparing for an interview for an Instrument Mechanic position can be daunting, but following these tips can increase your chances of success.

1. Research the Company and Position

Take the time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and the specific requirements of the job. It will also help you to prepare thoughtful questions to ask the interviewer.

- Visit the company’s website to learn about their history, products, and services.

- Read online reviews of the company to get insights into its culture and work environment.

- Study the job description carefully to identify the key responsibilities and qualifications.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Prepare a 30-second to 1-minute elevator pitch that summarizes your skills and experience.

- Practice answering questions about your technical skills, such as your experience with specific instruments or software.

- Be prepared to discuss your troubleshooting and problem-solving skills.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience as an Instrument Mechanic. Be prepared to discuss your responsibilities, accomplishments, and any challenges you have faced. Use specific examples to illustrate your skills and knowledge.

- Highlight your experience with different types of instruments and equipment.

- Share examples of troubleshooting and repair projects you have completed successfully.

- Discuss your experience with calibration and testing procedures.

4. Be Professional and Enthusiastic

First impressions matter, so it is important to dress professionally and arrive on time for your interview. Be polite and respectful to everyone you meet, including the receptionist and other employees. Show enthusiasm for the position and the company.

- Dress in appropriate business attire.

- Arrive on time for your interview.

- Be polite and respectful to everyone you meet.

- Show enthusiasm for the position and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Instrument Mechanic role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.