Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Instrument Person interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Instrument Person so you can tailor your answers to impress potential employers.

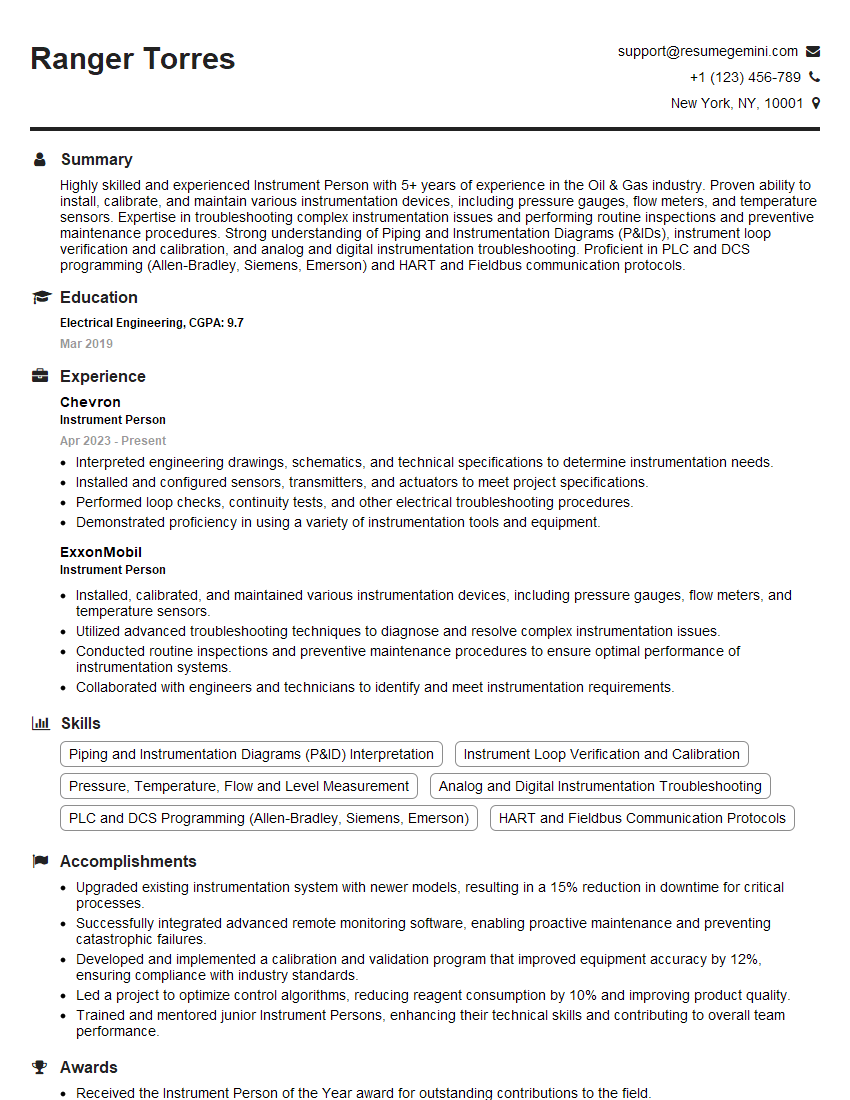

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument Person

1. How do you calibrate a pressure gauge?

To calibrate a pressure gauge, you will need the following:

- A pressure gauge

- A pressure source

- A reference pressure gauge

Once you have gathered your materials, follow these steps:

- Connect the pressure source to the pressure gauge that you want to calibrate.

- Connect the reference pressure gauge to the pressure source.

- Apply pressure to the pressure source.

- Compare the reading on the pressure gauge that you want to calibrate to the reading on the reference pressure gauge.

- Adjust the pressure gauge that you want to calibrate until the reading matches the reading on the reference pressure gauge.

2. What are the different types of flow meters and how do they work?

Turbine flow meter

- Turbine flow meters measure the volumetric flow rate of a fluid by measuring the rotation of a turbine that is placed in the flow path.

- The turbine is mounted on a shaft that is supported by bearings.

- As the fluid flows through the meter, it causes the turbine to rotate.

- The speed of rotation of the turbine is proportional to the flow rate of the fluid.

Vortex flow meter

- Vortex flow meters measure the volumetric flow rate of a fluid by measuring the shedding of vortices from a bluff body that is placed in the flow path.

- As the fluid flows past the bluff body, it creates a series of vortices that are shed from the body.

- The frequency of vortex shedding is proportional to the flow rate of the fluid.

Ultrasonic flow meter

- Ultrasonic flow meters measure the volumetric flow rate of a fluid by measuring the transit time of an ultrasonic signal that is transmitted through the fluid.

- The ultrasonic signal is transmitted from one transducer to another transducer that is located downstream.

- The transit time of the ultrasonic signal is proportional to the flow rate of the fluid.

3. What are the different types of level transmitters and how do they work?

- Diaphragm level transmitters measure the level of a liquid by measuring the deflection of a diaphragm that is in contact with the liquid.

- Bubbler level transmitters measure the level of a liquid by measuring the pressure of a gas that is bubbled through the liquid.

- Ultrasonic level transmitters measure the level of a liquid by measuring the transit time of an ultrasonic signal that is reflected off the surface of the liquid.

- Radar level transmitters measure the level of a liquid by measuring the transit time of a radar signal that is reflected off the surface of the liquid.

4. What are the different types of temperature sensors and how do they work?

- Thermocouples measure temperature by measuring the voltage that is generated by the junction of two dissimilar metals.

- Resistance temperature detectors (RTDs) measure temperature by measuring the change in resistance of a metal conductor as its temperature changes.

- Thermistors measure temperature by measuring the change in resistance of a semiconductor material as its temperature changes.

- Infrared temperature sensors measure temperature by measuring the amount of infrared radiation that is emitted by an object.

5. What are the different types of control valves and how do they work?

- Globe valves are used to control the flow of a fluid by moving a plug up and down inside a body.

- Gate valves are used to control the flow of a fluid by raising and lowering a gate that is perpendicular to the flow path.

- Ball valves are used to control the flow of a fluid by rotating a ball that has a hole through it.

- Butterfly vales are used to control the flow of a fluid by rotating a disc that is perpendicular to the flow path.

6. What are the different types of programmable logic controllers (PLCs) and how do they work?

- Compact PLCs are small PLCs that are designed for simple applications.

- Modular PLCs are PLCs that are built from a series of modules that can be added or removed as needed.

- Rack-mounted PLCs are PLCs that are mounted in a rack that is installed in a control panel.

- Distributed PLCs are PLCs that are distributed throughout a plant or facility.

7. What are the different types of fieldbus protocols and how do they work?

- Modbus is a serial communication protocol that is used to connect industrial devices.

- Profibus is a fieldbus protocol that is used to connect industrial devices in a distributed control system.

- DeviceNet is a fieldbus protocol that is used to connect industrial devices in a small to medium-sized control system.

- Ethernet/IP is a fieldbus protocol that is used to connect industrial devices in an Ethernet network.

8. What are the different types of distributed control systems (DCSs) and how do they work?

- Centralized DCSs are DCSs in which all of the control functions are performed by a single central computer.

- Decentralized DCSs are DCSs in which the control functions are distributed among a number of smaller computers.

- Hybrid DCSs are DCSs that combine features of both centralized and decentralized DCSs.

9. What are the different types of safety instrumented systems (SISs) and how do they work?

- Single-channel SISs are SISs that have a single channel for each safety function.

- Dual-channel SISs are SISs that have two channels for each safety function.

- Triple-channel SISs are SISs that have three channels for each safety function.

10. What are the different types of hazardous areas and how are they classified?

- Class I hazardous areas are areas in which flammable gases or vapors are present in the air in quantities sufficient to produce an explosive mixture.

- Class II hazardous areas are areas in which combustible dusts are present in the air in quantities sufficient to produce an explosive mixture.

- Class III hazardous areas are areas in which easily ignitable fibers or flyings are present in the air in quantities sufficient to produce an explosive mixture.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument Person.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument Person‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Instrument Persons are responsible for installing, maintaining, and calibrating instruments used in various industries, including manufacturing, construction, and scientific research. Their key responsibilities involve:

1. Instrument Installation

Installing and commissioning various types of instruments, such as pressure gauges, temperature sensors, flow meters, and control valves.

- Working closely with engineers and technicians to determine instrument locations and specifications.

- Ensuring proper installation and alignment of instruments according to technical drawings and specifications.

- Testing and calibrating instruments after installation to ensure accuracy and functionality.

2. Instrument Maintenance

Performing routine inspections and maintenance on instruments to ensure optimal performance and prevent malfunctions.

- Inspecting instruments for any signs of damage, wear, or improper functioning.

- Cleaning, lubricating, and repairing instruments as necessary to maintain their functionality.

- Replacing defective or outdated instruments with new ones.

3. Instrument Calibration

Calibrating instruments to ensure their accuracy and precision.

- Using specialized equipment and techniques to calibrate instruments against known standards.

- Documenting calibration procedures and results for compliance and quality control.

- Performing calibration adjustments to bring instruments within specified tolerances.

4. Troubleshooting and Repair

Diagnosing and repairing instrument malfunctions or breakdowns.

- Identifying the source of instrument problems through testing and analysis.

- Performing repairs or replacements to restore instrument functionality.

- Collaborating with engineers and technicians to resolve complex instrument issues.

Interview Tips

To ace an interview for an Instrument Person position, it’s essential to prepare thoroughly and demonstrate your technical proficiency and problem-solving abilities.

1. Research the Company and Position

Research the company and the specific role you’re applying for. This will help you understand their industry, products, and the requirements of the position.

- Visit the company’s website, read industry publications, and connect with current or former employees on LinkedIn.

- Identify the key responsibilities and qualifications required for the role, and tailor your resume and answers accordingly.

2. Highlight Technical Skills and Experience

Emphasize your technical skills and relevant experience, including your knowledge of instrument installation, maintenance, calibration, and troubleshooting.

- Provide specific examples of projects or situations where you successfully installed, maintained, or repaired instruments.

- Quantify your accomplishments whenever possible, using metrics like accuracy levels achieved or time saved.

3. Demonstrate Problem-Solving Abilities

Showcase your ability to identify, diagnose, and resolve instrument problems efficiently.

- Describe a situation where you encountered a challenging instrument malfunction and explain how you systematically approached the problem.

- Highlight your analytical skills and your experience using troubleshooting techniques and equipment.

4. Emphasize Attention to Detail

Instrument Persons require meticulous attention to detail to ensure the accuracy and reliability of their work.

- Explain how you maintain detailed records, follow safety protocols, and ensure the proper functioning of instruments.

- Discuss your commitment to quality control and your ability to meet or exceed industry standards.

5. Practice and Prepare

Practice answering common interview questions and prepare examples to illustrate your skills and experience. This will boost your confidence and help you deliver clear and concise responses during the interview.

- Research common interview questions for Instrument Persons, such as “Describe your experience calibrating a flow meter” or “How do you troubleshoot a pressure gauge malfunction?”

- Prepare specific examples from your experience that demonstrate your technical proficiency, problem-solving abilities, and attention to detail.

Next Step:

Now that you’re armed with the knowledge of Instrument Person interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Instrument Person positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini