Are you gearing up for an interview for a Instrument Specialist position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Instrument Specialist and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

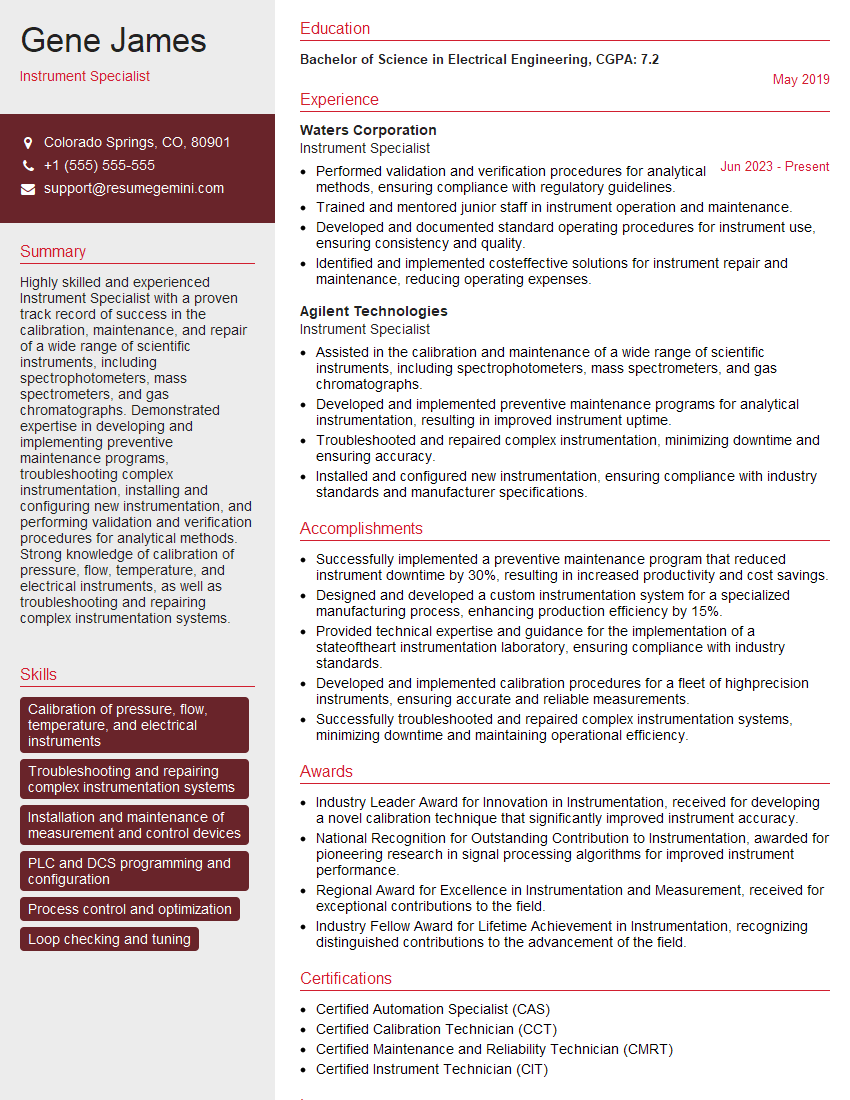

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument Specialist

1. How would you go about troubleshooting a faulty flow meter?

- Begin by physically inspecting the flow meter for any leaks or obstructions.

- Verify the flow rate and compare it to the expected values.

- Check the electrical connections and wiring to ensure proper power supply.

- Examine the transmitter’s output signal and compare it to the manufacturer’s specifications.

- Use a multimeter to test the resistance, voltage, and continuity of the flow meter’s components.

- Consider the process conditions, such as temperature, pressure, and fluid viscosity.

2. Explain the calibration process for a pressure gauge.

Pressure Source Selection

- Select a pressure source that can generate a stable and accurate pressure within the gauge’s range.

Zero Calibration

- Apply zero pressure to the gauge.

- Adjust the gauge’s zero point until it reads 0.

Span Calibration

- Apply a known pressure, typically the full scale of the gauge.

- Adjust the gauge’s span until it reads the correct pressure.

Verification

- Apply various pressures throughout the gauge’s range.

- Ensure that the gauge’s readings are accurate and consistent.

3. Describe the different types of thermocouples and their applications.

- Type J (Iron-Constantan): Wide temperature range (-210°C to 1200°C), commonly used in low-temperature applications.

- Type K (Chromel-Alumel): Good accuracy and stability (-200°C to 1372°C), widely used in industrial processes.

- Type T (Copper-Constantan): Low temperature range (-200°C to 400°C), suitable for cryogenic applications.

- Type E (Chromel-Constantan): High temperature range (0°C to 982°C), often used in high-temperature furnaces.

4. How do you ensure the accuracy of a weighing scale?

- Calibration: Regularly calibrate the scale using certified weights to ensure accurate readings.

- Zero Point Check: Check the zero point before each use to ensure the scale reads zero when nothing is on the platform.

- Leveling: Ensure the scale is level to prevent incorrect readings due to uneven weight distribution.

- Environmental Conditions: Consider the operating environment, such as temperature changes, vibrations, and dust, which can affect accuracy.

5. Discuss the advantages of using a HART protocol in industrial instrumentation.

- Real-Time Data Access: Allows remote monitoring of instrument parameters, such as temperature, pressure, and flow.

- Device Configuration: Enables remote configuration of instrument settings, reducing maintenance time.

- Diagnostics: Provides diagnostic information about instrument status, aiding in troubleshooting and predictive maintenance.

- Reduced Wiring: HART uses a single pair of wires for both communication and power, simplifying wiring and installation.

6. How would you approach designing an instrumentation system for a new facility?

- Process Understanding: Thoroughly understand the process requirements, operating conditions, and safety regulations.

- Instrument Selection: Choose appropriate instruments based on process parameters, accuracy requirements, and environmental factors.

- System Architecture: Design a system architecture that meets communication, data acquisition, and control needs.

- Calibration and Validation: Plan for regular calibration and validation procedures to ensure instrument accuracy and reliability.

7. Explain the role of programmable logic controllers (PLCs) in automation.

- Process Control: PLCs monitor and control various process variables, such as temperature, pressure, and flow.

- Logic Functions: Handle complex logic operations, including sequencing, timing, and fault detection.

- Data Acquisition: Collect data from sensors and instruments, providing real-time process information.

- Communication: Interface with other control systems, HMIs, and remote devices.

8. How do you handle calibration and maintenance of instrumentation systems?

- Calibration Management: Establish calibration schedules and procedures to ensure instrument accuracy.

- Preventive Maintenance: Perform regular inspections, cleaning, and lubrication to prevent breakdowns.

- Documentation: Keep detailed records of calibration and maintenance activities for traceability and compliance.

- Training: Ensure technicians are trained in proper calibration and maintenance techniques.

9. Discuss the different types of level measurement technologies and their applications.

- Capacitance: Measures level by sensing capacitance changes between electrodes and the medium.

- Ultrasonic: Uses sound waves to determine level by measuring the time taken for the waves to reflect from the surface.

- Radar: Similar to ultrasonic, but uses high-frequency radio waves to measure level.

- Differential Pressure: Measures the pressure difference between the top and bottom of a vessel to infer the level.

- Float-Based: Uses a float to indicate the level, either directly or through a mechanical linkage.

10. Explain the use of data loggers in industrial instrumentation.

- Data Acquisition: Collect data from sensors and instruments over time.

- Process Monitoring: Monitor process parameters remotely, enabling early detection of deviations.

- Trend Analysis: Provide historical data for trend analysis and process optimization.

- Quality Control: Ensure compliance with quality standards by recording and storing data related to production processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument Specialist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument Specialist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Instrument Specialists are responsible for the maintenance, calibration, and repair of scientific instruments used in various industries, including research, manufacturing, and healthcare. Their key responsibilities include:

1. Maintenance and Calibration

Perform routine maintenance tasks such as cleaning, lubrication, and adjustment to ensure optimal instrument performance

- Calibrate instruments against established standards to ensure accuracy and reliability

- Troubleshoot and diagnose instrument malfunctions and resolve issues efficiently

2. Repair and Troubleshooting

Identify and repair instrument faults using specialized tools and techniques

- Analyze instrument schematics and diagnose electrical or mechanical problems

- Replace faulty components, adjust settings, and verify instrument functionality

3. Documentation and Reporting

Maintain accurate records of instrument maintenance, calibration, and repair activities

- Create reports documenting instrument performance and any issues encountered

- Provide technical assistance and guidance to users on instrument operation and maintenance

4. Training and Development

Provide training to users on proper instrument handling and maintenance techniques

- Stay up-to-date with industry best practices and advancements in instrument technology

- Participate in professional development programs to enhance skills and knowledge

Interview Tips

Preparing for an Instrument Specialist interview requires understanding the key responsibilities and developing effective strategies to demonstrate your qualifications. Here are some interview tips to help you ace the interview:

1. Research the Company and Role

Thoroughly research the company’s industry, products, and services to understand their business needs.

- Review the job description carefully to identify the specific requirements and expectations

- Practice tailoring your responses to the company’s needs and how your skills align with their requirements

2. Highlight Your Technical Expertise

Emphasize your strong understanding of instrumentation principles, calibration techniques, and troubleshooting methods.

- Provide specific examples of your experience in maintaining, calibrating, and repairing various types of instruments

- Discuss your knowledge of industry standards and regulations related to instrument usage

3. Showcase Your Analytical and Problem-Solving Skills

Instrument Specialists often encounter complex problems that require analytical thinking and problem-solving abilities.

- Use the STAR method (Situation, Task, Action, Result) to describe how you successfully diagnosed and resolved instrument issues

- Emphasize your ability to think critically, analyze data, and identify root causes of problems

4. Prepare for Common Interview Questions

Anticipate and prepare answers to common interview questions related to your experience, skills, and career goals.

- Examples of common questions include: “Describe your experience in calibrating analytical instruments,” “How do you approach troubleshooting complex instrument malfunctions?”

- Practice your responses and tailor them to demonstrate your relevant qualifications and enthusiasm for the role

5. Ask Thoughtful Questions

Preparing thoughtful questions to ask the interviewer shows your engagement and interest in the role.

- Inquire about the company’s current instrumentation projects, their plans for future technology implementation, or the opportunities for professional development

- Asking insightful questions demonstrates your curiosity and eagerness to learn more about the company and the position

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Instrument Specialist interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.