Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Instrument Technician Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

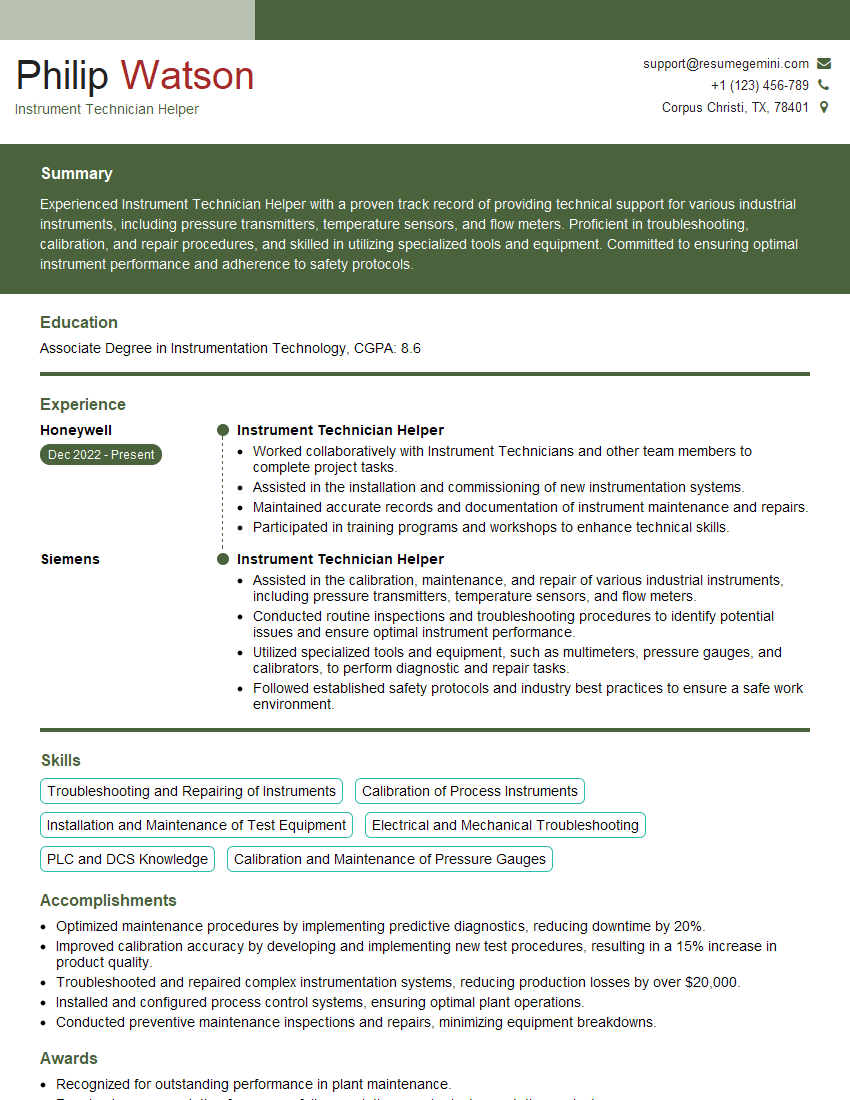

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument Technician Helper

1. Describe the role of an Instrument Technician Helper in a typical work environment.

The Instrument Technician Helper assists the Instrument Technician in the installation, maintenance, and repair of industrial instrumentation and control systems. They may also be responsible for calibrating and testing instruments, as well as troubleshooting and repairing malfunctioning equipment.

- Assists the Instrument Technician in the installation, maintenance, and repair of industrial instrumentation and control systems.

- May be responsible for calibrating and testing instruments.

- May also be responsible for troubleshooting and repairing malfunctioning equipment.

- Works under the supervision of an Instrument Technician.

- May be required to work in hazardous or confined spaces.

2. Explain the purpose of a loop check and how it is performed.

Pressure Transmitter

- A loop check is a procedure used to verify the integrity of a control loop.

- It involves applying a known input signal to the loop and measuring the output signal.

- For a pressure transmitter, a loop check can be performed by applying a known pressure to the transmitter and measuring the output signal.

- The output signal should be within the expected range for the given input pressure.

Temperature Transmitter

- A loop check for a temperature transmitter can be performed by applying a known temperature to the transmitter and measuring the output signal.

- The output signal should be within the expected range for the given input temperature.

3. Describe the different types of pressure gauges and their applications.

There are many different types of pressure gauges, each with its own unique application.

- Bourdon tube pressure gauge: This is a common type of pressure gauge that uses a curved tube to measure pressure.

- Diaphragm pressure gauge: This type of pressure gauge uses a diaphragm to measure pressure.

- Digital pressure gauge: This type of pressure gauge uses a digital display to show the pressure reading.

- Absolute pressure gauge: This type of pressure gauge measures the absolute pressure of a gas or liquid.

- Differential pressure gauge: This type of pressure gauge measures the difference in pressure between two points.

4. Explain the difference between a 4-20 mA signal and a 0-10 V signal.

A 4-20 mA signal is a current loop signal that is used to transmit analog signals over long distances.

A 0-10 V signal is a voltage signal that is also used to transmit analog signals over long distances.

- 4-20 mA signal: This signal is typically used in industrial applications because it is less susceptible to noise than a 0-10 V signal.

- 0-10 V signal: This signal is typically used in commercial applications because it is easier to generate and amplify than a 4-20 mA signal.

5. Describe the purpose of a solenoid valve and how it works.

A solenoid valve is an electromechanically operated valve that is used to control the flow of a fluid.

- Solenoid valves are typically used in industrial applications to control the flow of liquids or gases.

- When the solenoid is energized, it creates a magnetic field that opens or closes the valve.

- Solenoid valves can be used to control the flow of a variety of fluids, including water, oil, and gas.

6. Explain the difference between a PLC and a DCS.

A PLC (programmable logic controller) is a digital computer that is used to control industrial processes.

A DCS (distributed control system) is a computer-based control system that is used to control large-scale industrial processes.

- PLC: A PLC is a standalone unit that is typically used to control small to medium-sized processes.

- DCS: A DCS is a network of computers that is used to control large-scale processes.

7. Describe the purpose of a HART device and how it is used.

A HART device is a device that uses the HART (Highway Addressable Remote Transducer) protocol to communicate with a host system.

- HART devices are typically used in industrial applications to transmit data from field devices to a host system.

- HART devices can be used to transmit a variety of data, including process variables, diagnostic information, and configuration data.

- HART devices are typically used in conjunction with a HART modem to communicate with a host system.

8. What is the difference between a transmitter and a transducer?

A transmitter is a device that converts a physical quantity into an electrical signal.

A transducer is a device that converts one form of energy into another form of energy.

- Transmitter: A transmitter is typically used to convert a physical quantity, such as temperature or pressure, into an electrical signal.

- Transducer: A transducer can be used to convert a variety of energy forms, such as mechanical energy into electrical energy or electrical energy into mechanical energy.

9. Describe the purpose of a control valve and how it is used.

A control valve is a device that is used to control the flow of a fluid.

- Control valves are typically used in industrial applications to control the flow of liquids or gases.

- Control valves can be used to control the flow of a variety of fluids, including water, oil, and gas.

- Control valves are typically operated by a pneumatic or electric actuator.

10. Explain the difference between an analog signal and a digital signal.

An analog signal is a continuous signal that can take on any value within a certain range.

A digital signal is a discrete signal that can only take on a finite number of values.

- Analog signal: An analog signal is typically used to represent a continuously varying quantity, such as temperature or pressure.

- Digital signal: A digital signal is typically used to represent a discrete quantity, such as a binary number.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument Technician Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument Technician Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Instrument Technician Helper, you will be responsible for assisting senior technicians in the installation, maintenance, and repair of instrumentation and control systems.

1. Assist with Instrument Installation and Repair

You will help with installing, calibrating, and configuring new instrumentation. You will also assist with troubleshooting and repairing existing instruments.

- Install and commission new instruments according to manufacturers’ specifications

- Troubleshoot and repair faulty instruments

- Calibrate instruments to ensure accuracy

2. Assist with Maintenance and Calibration

You will help with preventive maintenance tasks, such as cleaning and inspecting instruments. You will also assist with calibrating instruments to ensure they are operating within specification.

- Perform preventive maintenance tasks on instruments, such as cleaning and lubrication

- Calibrate instruments to ensure accuracy

- Inspect instruments for damage and wear

3. Assist with Documentation and Record Keeping

You will help with documenting instrument installations and repairs. You will also help with maintaining records of instrument maintenance and calibration.

- Document instrument installations and repairs

- Maintain records of instrument maintenance and calibration

- Create and maintain technical manuals and drawings

4. Safety and Compliance

You will be responsible for adhering to all safety regulations and procedures. You will also be responsible for ensuring that all work is completed in accordance with industry standards.

- Follow all safety regulations and procedures

- Ensure that all work is completed in accordance with industry standards

- Participate in safety training and drills

Interview Tips

To ace your interview for an Instrument Technician Helper position, follow these tips:

1. Research the Company and Position

Take some time to research the company you’re interviewing with and the position you’re applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website and social media pages

- Read news articles and press releases about the company

- Review the job description carefully

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you’re likely to be asked. Practice answering these questions in advance so that you can deliver your responses confidently and concisely.

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

3. Be Enthusiastic and Positive

Employers are looking for candidates who are enthusiastic and positive. Show the interviewer that you’re excited about the opportunity to work for their company and that you’re confident in your abilities.

- Smile and make eye contact with the interviewer

- Speak clearly and confidently

- Be positive and enthusiastic about your work

4. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the workplace.

- Wear a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and pressed

- Avoid wearing casual clothes, such as jeans or t-shirts

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Instrument Technician Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Instrument Technician Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.