Are you gearing up for an interview for a Instrument Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Instrument Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

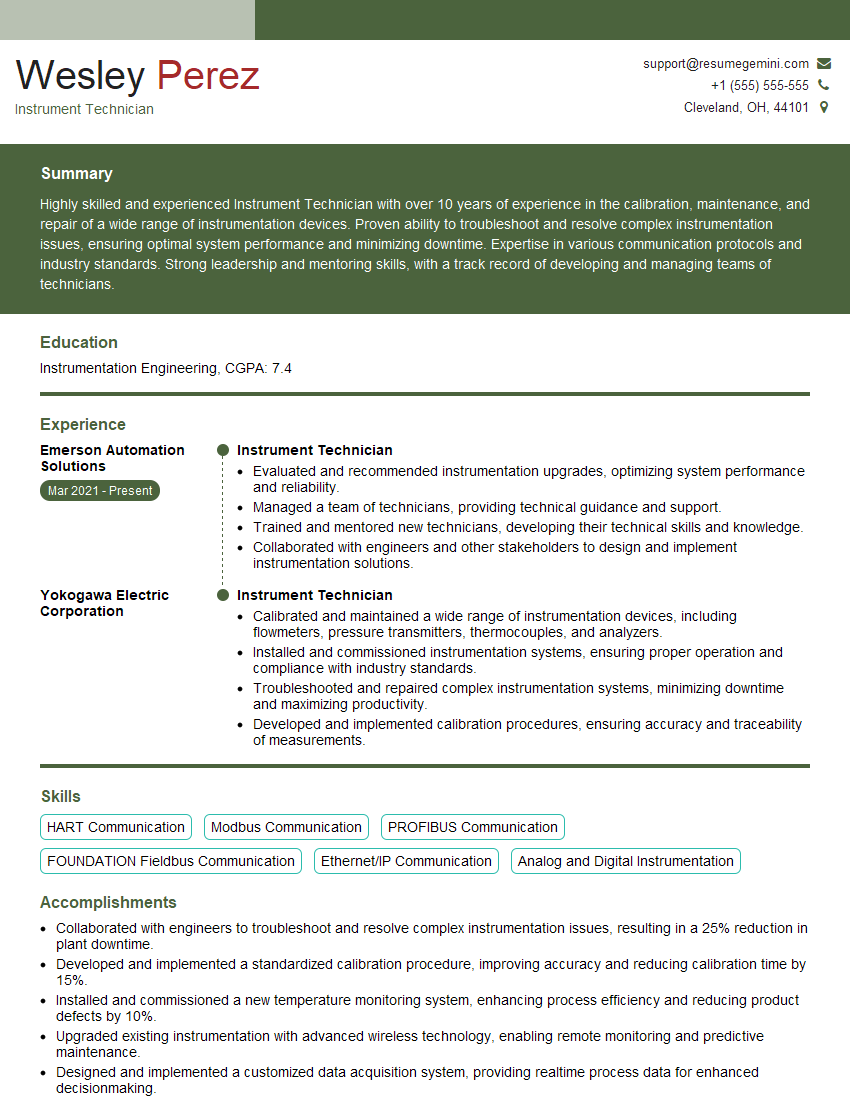

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument Technician

1. How would you calibrate a pressure transmitter?

To calibrate a pressure transmitter, I would follow these steps:

- Connect a pressure source to the transmitter.

- Apply a known pressure to the transmitter.

- Measure the output signal from the transmitter.

- Compare the output signal to the expected output signal.

- Adjust the transmitter’s calibration until the output signal matches the expected output signal.

2. What are the different types of flow meters?

Turbine flow meter

- A turbine flow meter uses a turbine to measure the flow rate of a fluid.

- The fluid flows through the turbine, causing it to spin.

- The speed of the turbine is proportional to the flow rate of the fluid.

Orifice plate flow meter

- An orifice plate flow meter uses an orifice plate to measure the flow rate of a fluid.

- The orifice plate is a thin plate with a hole in the center.

- The fluid flows through the hole in the orifice plate, and the pressure drop across the orifice plate is proportional to the flow rate of the fluid.

3. How would you troubleshoot a temperature sensor that is not reading correctly?

To troubleshoot a temperature sensor that is not reading correctly, I would follow these steps:

- Check the connections to the temperature sensor.

- Check the wiring to the temperature sensor.

- Check the power supply to the temperature sensor.

- Check the calibration of the temperature sensor.

- Replace the temperature sensor if necessary.

4. What are the different types of control valves?

Globe valve

- A globe valve is a type of control valve that uses a ball to control the flow of fluid.

- The ball is attached to a stem, which is turned to open or close the valve.

- Globe valves are used in a variety of applications, including water supply, gas supply, and chemical processing.

Butterfly valve

- A butterfly valve is a type of control valve that uses a butterfly-shaped disc to control the flow of fluid.

- The disc is attached to a shaft, which is turned to open or close the valve.

- Butterfly valves are used in a variety of applications, including water supply, gas supply, and chemical processing.

5. How would you install a new instrument in a process control system?

To install a new instrument in a process control system, I would follow these steps:

- Read the manufacturer’s instructions for the instrument.

- Select a location for the instrument that is close to the process and has easy access for maintenance.

- Mount the instrument according to the manufacturer’s instructions.

- Connect the instrument to the process and the control system.

- Calibrate the instrument according to the manufacturer’s instructions.

- Test the instrument to make sure it is working properly.

6. What is the difference between a PID controller and a fuzzy logic controller?

PID controller

- A PID controller is a type of feedback controller that uses a proportional-integral-derivative (PID) algorithm to control the output of a system.

- The PID algorithm uses the error between the desired output and the actual output to calculate the output of the controller.

- PID controllers are used in a variety of applications, including temperature control, pressure control, and flow control.

Fuzzy logic controller

- A fuzzy logic controller is a type of feedback controller that uses fuzzy logic to control the output of a system.

- Fuzzy logic is a type of logic that uses approximate values and imprecise information to make decisions.

- Fuzzy logic controllers are used in a variety of applications, including robotics, image processing, and speech recognition.

7. What are the different types of programmable logic controllers (PLCs)?

Compact PLC

- A compact PLC is a small PLC that is designed for use in small applications.

- Compact PLCs typically have a limited number of inputs and outputs (I/O) and are programmed using a simple programming language.

Modular PLC

- A modular PLC is a PLC that is made up of a number of different modules that can be added or removed to increase or decrease the I/O capacity of the PLC.

- Modular PLCs are typically used in larger applications and are programmed using a more complex programming language.

8. What are the different types of communication protocols used in industrial automation?

Modbus

- Modbus is a serial communication protocol that is used to connect devices in industrial automation systems.

- Modbus is a simple protocol that is easy to implement and use.

Profibus

- Profibus is a fieldbus communication protocol that is used to connect devices in industrial automation systems.

- Profibus is a more complex protocol than Modbus, but it offers more features and capabilities.

9. What are the different types of safety systems used in industrial automation?

Emergency stop system

- An emergency stop system is a safety system that is used to stop a machine or process in the event of an emergency.

- Emergency stop systems are typically activated by a button or switch that is located in a visible and accessible location.

Interlock system

- An interlock system is a safety system that is used to prevent a machine or process from operating unless certain conditions are met.

- Interlock systems are typically used to protect personnel from hazards such as moving machinery or electrical shocks.

10. What are the different types of documentation used in industrial automation?

Functional specification

- A functional specification is a document that describes the requirements for a machine or process.

- Functional specifications are used to communicate the requirements of the machine or process to the design and engineering teams.

Design specification

- A design specification is a document that describes the design of a machine or process.

- Design specifications are used to communicate the design of the machine or process to the manufacturing and installation teams.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Instrument Technicians play a vital role in maintaining and repairing instruments used in various industries. Their responsibilities encompass a wide range of tasks, including:

1. Installation and Maintenance

Instrument Technicians are responsible for the installation, maintenance, and calibration of instruments. They ensure that the instruments are functioning correctly and meet the required specifications.

- Install new instruments and equipment

- Calibrate and maintain instruments to ensure accuracy

- Inspect and test instruments to identify potential issues

2. Troubleshooting and Repair

When instruments malfunction, Instrument Technicians are tasked with troubleshooting and repairing them. They diagnose the problem and determine the best course of action to restore functionality.

- Analyze instrument readings and identify problems

- Repair or replace faulty components

- Troubleshoot and resolve instrument malfunctions

3. Documentation and Communication

Instrument Technicians maintain detailed records of their work, including installation, maintenance, and repair activities. They also collaborate with engineers, operators, and other technicians to ensure proper instrument operation.

- Record maintenance and repair activities

- Communicate with engineers and operators about instrument performance

- Prepare technical reports and documentation

4. Safety and Compliance

Instrument Technicians prioritize safety in their work, adhering to established protocols and regulations. They also ensure that instruments meet industry standards and environmental regulations.

- Follow safety procedures and regulations

- Comply with industry standards and environmental requirements

- Promote safe work practices

Interview Tips

Preparing for an Instrument Technician interview requires a combination of technical knowledge and interview skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, products or services, and the specific requirements of the Instrument Technician position. This demonstrates your interest and eagerness to learn more about the opportunity.

- Visit the company’s website and social media pages

- Read industry news and articles relevant to the position

- Study the job description thoroughly

2. Practice Your Technical Skills

Be prepared to discuss your technical abilities and experience in detail. Review basic instrument principles, troubleshooting techniques, and industry terminology. Consider practicing common interview questions related to your technical skills.

- Review fundamental instrument theory and calibration principles

- Practice common troubleshooting scenarios

- Prepare to explain your experience with specific instruments or software

3. Highlight Your Work Experience

Emphasize your relevant work experience, quantifying your accomplishments whenever possible. Use specific examples to demonstrate your troubleshooting abilities, problem-solving skills, and commitment to safety.

- Describe projects or tasks where you successfully resolved complex instrument issues

- Provide examples of how your work contributed to improved instrument performance or safety

- Quantify your achievements using specific metrics

4. Prepare for Behavioral Questions

Interviewers often ask behavioral questions to assess your interpersonal skills, work ethic, and problem-solving abilities. Consider common behavioral interview questions and prepare thoughtful answers that showcase your strengths.

- Practice answering questions about teamwork, conflict resolution, and handling pressure

- Provide specific examples that demonstrate your positive work habits and interpersonal skills

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Instrument Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Instrument Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.