Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Instrument Tester interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Instrument Tester so you can tailor your answers to impress potential employers.

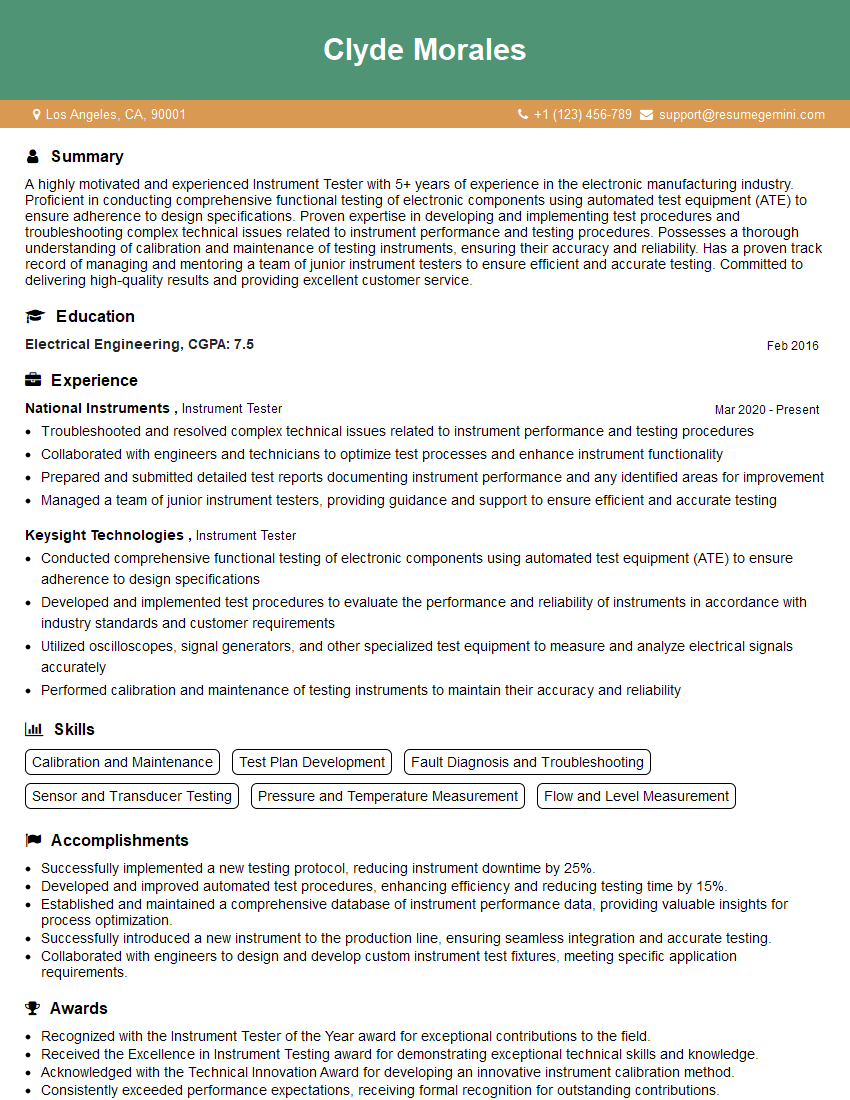

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument Tester

1. What are the different types of instrument testing?

There are various types of instrument testing, including:

- Functional testing: Verifies that the instrument performs its intended functions correctly.

- Calibration testing: Ensures that the instrument’s measurements are accurate and consistent.

- Safety testing: Assesses the instrument’s safety features and compliance with regulations.

- Environmental testing: Evaluates the instrument’s performance under extreme conditions, such as temperature, humidity, and vibration.

- Reliability testing: Determines the instrument’s ability to withstand prolonged use and maintain its accuracy.

- Maintenance testing: Monitors the instrument’s performance over time and identifies any potential issues that may require maintenance or repair.

2. What are the key considerations when selecting test equipment for instrument testing?

Accuracy and precision:

- The test equipment should provide accurate and precise measurements that align with the instrument’s specifications.

Range and resolution:

- The test equipment should have a measurement range that covers the instrument’s operating parameters and sufficient resolution to capture subtle changes.

Calibration and traceability:

- The test equipment should be calibrated regularly using a traceable reference standard to ensure its measurements are reliable.

Ease of use and efficiency:

- The test equipment should be user-friendly, allowing for efficient and streamlined testing procedures.

Compliance with industry standards:

- The test equipment should comply with relevant industry standards or regulations to ensure its measurements are recognized and accepted.

3. Describe the process of calibrating an instrument.

Instrument calibration typically involves the following steps:

- Preparation: Gather necessary equipment, materials, and documentation, and ensure the instrument is ready for calibration.

- Reference selection: Establish a traceable reference standard or source against which the instrument will be compared.

- Comparison and adjustment: Use the reference standard to take measurements and compare them to the instrument’s readings. Make necessary adjustments to the instrument to minimize deviations.

- Data recording: Document the calibration results, including measurement values, adjustment parameters, and any deviations observed.

- Verification: Perform post-calibration tests to ensure the instrument meets specified accuracy requirements.

- Certification: If applicable, issue a calibration certificate that confirms the instrument’s performance and traceability.

4. How do you troubleshoot a faulty instrument?

Troubleshooting a faulty instrument involves a systematic approach:

- Observation and questioning: Inspect the instrument for any obvious damage or abnormalities, and gather information about its recent use and operating conditions.

- Testing and diagnosis: Perform diagnostic tests to identify the specific issue, such as checking power supply, signal connections, or software functionality.

- Isolation and repair: Isolate the faulty component or area and make necessary repairs or replacements.

- Verification and documentation: Verify the instrument’s restored functionality through testing and document the troubleshooting process for future reference.

5. What are some common sources of error in instrument testing?

Common sources of error in instrument testing include:

- Calibration errors: Incorrectly calibrated or uncalibrated instruments may provide inaccurate measurements.

- Environmental factors: Temperature, humidity, or electromagnetic interference can affect instrument performance and introduce errors.

- Human errors: Misreading or misinterpreting instrument readings, mishandling instruments, or incorrect test procedures can lead to errors.

- Equipment limitations: Using test equipment with insufficient accuracy or range may provide unreliable results.

- Sample variability: Variations in the sample being tested can impact instrument readings and introduce errors.

6. How do you ensure the quality and reliability of instrument test results?

To ensure the quality and reliability of instrument test results:

- Calibrate instruments regularly using traceable reference standards.

- Follow standardized test procedures and protocols to minimize human errors.

- Control environmental conditions within specified limits to prevent external influences on instrument performance.

- Perform multiple measurements and compare results for consistency.

- Document test procedures, results, and any deviations or anomalies for traceability and auditing purposes.

7. What are the ethical responsibilities of an instrument tester?

As an instrument tester, ethical responsibilities include:

- Maintaining objectivity and impartiality in testing and reporting results.

- Adhering to industry standards and regulations to ensure the integrity and validity of test data.

- Confidentiality and protection of sensitive information obtained during testing.

- Providing accurate and reliable test results without bias or external influence.

- Upholding ethical conduct in all professional interactions and avoiding any conflicts of interest.

8. Describe a challenging instrument testing project you have worked on. How did you approach it and overcome the challenges?

In a challenging instrument testing project, I encountered several roadblocks:

- Inaccurate instrument readings: The instrument was providing inconsistent and unreliable measurements.

- Limited access to reference standards: Traceable reference standards for calibration were not readily available.

- Environmental constraints: The testing environment had extreme temperature and humidity fluctuations.

To overcome these challenges, I:

- Troubleshooted the instrument: I performed diagnostic tests to isolate the source of the measurement errors and identified a faulty component.

- Established an alternative calibration method: In the absence of traceable reference standards, I developed a calibration procedure using in-house resources and validated its accuracy through rigorous testing.

- Controlled the environmental conditions: I implemented environmental controls, such as temperature regulation and humidity monitoring, to minimize external influences on instrument performance.

9. How do you stay updated with the latest advancements in instrument testing techniques and technologies?

To stay updated with the latest advancements in instrument testing, I:

- Attend industry conferences and workshops.

- Subscribe to technical journals and online forums.

- Engage in professional development courses and certifications.

- Collaborate with colleagues and experts in the field.

- Explore new technologies and research publications.

10. What is your understanding of the role of instrument testing in ensuring product quality and safety?

Instrument testing plays a crucial role in ensuring product quality and safety by providing:

- Objective evaluation: Instruments provide accurate and quantifiable measurements, eliminating subjective assessments and ensuring consistency in product performance.

- Early detection of defects: Testing can identify potential defects or non-conformities at an early stage, allowing for corrective actions to prevent product failures.

- Compliance with regulations: Testing ensures that products meet industry standards and regulatory requirements, protecting consumers and the environment.

- Traceability and documentation: Test results provide traceable evidence of product performance and compliance, facilitating quality audits and investigations.

- Continuous improvement: By evaluating instrument data, manufacturers can identify areas for improvement and optimize product design and manufacturing processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Instrument Tester is responsible for ensuring the accuracy and precision of various instruments and equipment used in different fields. Their primary duties include:

1. Instrument Testing and Calibration

Conducting thorough testing and calibration of instruments, such as electrical meters, pressure gauges, flow meters, and temperature sensors, to ensure their compliance with established standards.

2. Troubleshooting and Repairs

Diagnosing and troubleshooting issues with instruments and performing necessary repairs or adjustments to maintain their functionality and accuracy.

3. Preventive Maintenance

Performing preventive maintenance on instruments to extend their lifespan and ensure optimal performance, including regular cleaning, lubrication, and component replacement.

4. Documentation and Reporting

Maintaining accurate records of test results, maintenance activities, and repairs to ensure traceability and compliance with quality standards.

Interview Tips

To ace an interview for an Instrument Tester position, candidates should focus on the following key areas:

1. Technical Expertise

Demonstrate a comprehensive understanding of instrument testing and calibration techniques, including relevant industry standards and regulations.

2. Troubleshooting Abilities

Highlight strong troubleshooting skills, emphasizing the ability to identify and resolve complex technical issues efficiently.

3. Attention to Detail

Emphasize meticulous attention to detail, precision, and accuracy in performing testing and maintenance procedures.

4. Communication Skills

Showcase effective communication skills, both written and verbal, to convey test results, recommendations, and technical information to various stakeholders.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Instrument Tester interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!