Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Instrumentation and Electrical Preventive Maintenance Inspector IE PM Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

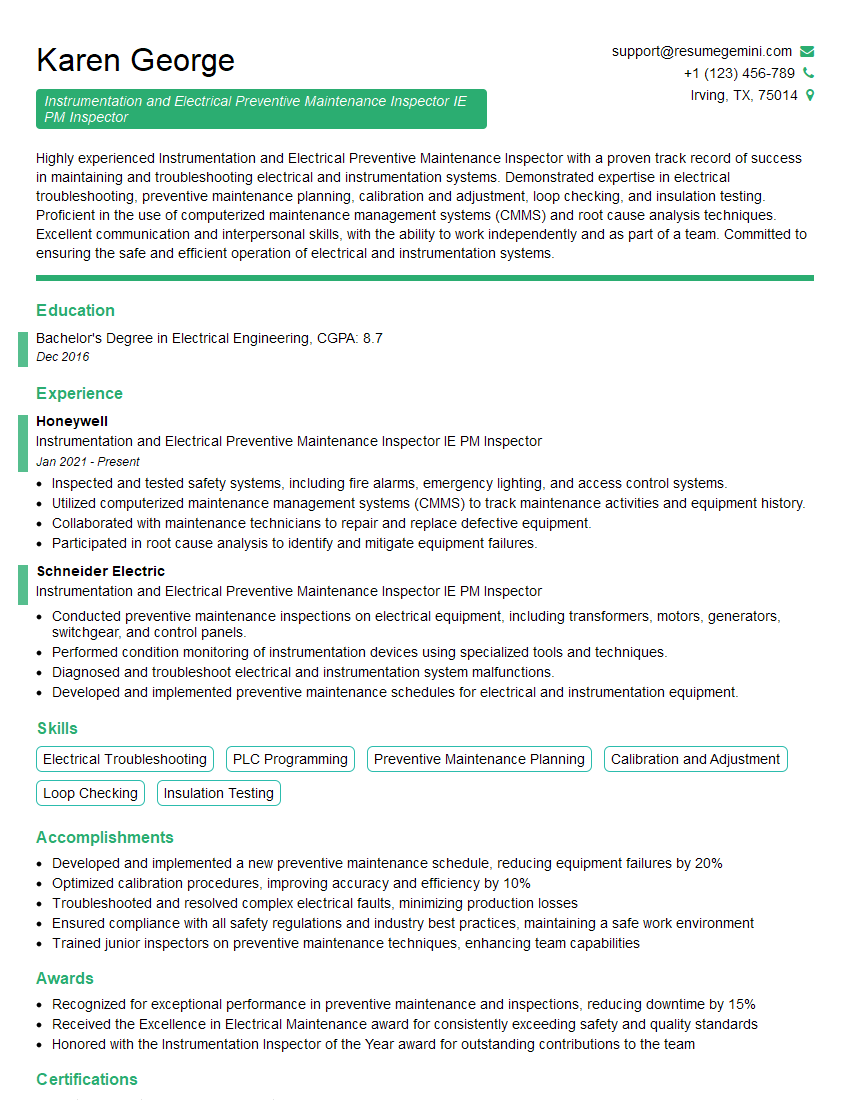

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrumentation and Electrical Preventive Maintenance Inspector IE PM Inspector

1. What are the key responsibilities of an Instrumentation and Electrical Preventive Maintenance Inspector (IE PM Inspector)?

As an IE PM Inspector, my primary responsibilities include:

- Performing preventive maintenance and inspections on instrumentation and electrical equipment to ensure optimal performance and minimize downtime.

- Inspecting equipment for signs of wear, damage, or malfunction, and taking appropriate corrective actions.

- Monitoring equipment performance and identifying potential issues before they become major problems.

- Documenting findings, recommending repairs, and coordinating with maintenance teams to ensure timely and effective maintenance.

- Staying up-to-date on industry best practices and emerging technologies to enhance maintenance strategies.

2. Explain the process of conducting a preventive maintenance inspection on a Programmable Logic Controller (PLC).

To conduct a preventive maintenance inspection on a PLC, I follow these steps:

Visual Inspection

- Inspect the PLC for any physical damage, loose connections, or signs of corrosion.

- Check the condition of wires, terminals, and connectors.

Functional Testing

- Power up the PLC and verify its basic functionality.

- Test inputs and outputs using diagnostic tools.

- Check the PLC’s memory, communication ports, and other components.

Software Maintenance

- Inspect the PLC’s firmware and software for any updates or issues.

- Perform necessary software updates or patches.

- Check the status of the PLC’s backup battery.

Documentation

- Document all findings, including any issues or recommendations for repairs.

- Generate a maintenance report and schedule follow-up inspections as needed.

3. What are some common faults that you have encountered in electrical motors during preventive maintenance inspections?

During preventive maintenance inspections, I have encountered various common faults in electrical motors, including:

- Worn or damaged bearings, which can cause excessive vibration and noise.

- Damaged insulation on windings, which can lead to short circuits and overheating.

- Loose or broken connections, which can cause power interruptions and equipment failure.

- Overheating due to ventilation issues, overloading, or bearing failures.

- Rotor or stator damage, which can result in reduced performance or complete failure.

4. How do you prioritize preventive maintenance tasks based on risk and criticality?

To prioritize preventive maintenance tasks, I consider the following factors:

- Risk assessment: Evaluating the potential consequences of equipment failure, including safety hazards, production downtime, and financial impact.

- Criticality: Determining the importance of the equipment for overall production processes and operations.

- Equipment condition: Assessing the current condition of the equipment based on previous inspections, performance data, and maintenance history.

- Manufacturer’s recommendations: Following industry standards and guidelines for preventive maintenance intervals.

- Resource availability: Considering the availability of personnel, tools, and materials required for maintenance tasks.

5. What are your key performance indicators (KPIs) as an IE PM Inspector?

My key performance indicators include:

- Equipment uptime: Percentage of time that equipment is operational without unplanned downtime.

- Maintenance backlog: Number of outstanding preventive maintenance tasks.

- Mean time between failures (MTBF): Average time between equipment failures.

- Mean time to repair (MTTR): Average time required to repair equipment after a failure.

- Customer satisfaction: Feedback from maintenance clients on the quality and effectiveness of preventive maintenance services.

6. How do you stay up-to-date on best practices and technological advancements in the field of instrumentation and electrical preventive maintenance?

To stay up-to-date, I engage in the following activities:

- Attending industry conferences and workshops.

- Reading technical journals, whitepapers, and industry publications.

- Participating in online forums and discussions.

- Completing professional development courses and certifications.

- Consulting with experts in the field and collaborating with colleagues.

7. Describe a situation where you had to troubleshoot a complex instrumentation or electrical problem.

In a recent situation, I encountered a complex issue with a temperature control system that was causing erratic temperature fluctuations. Following a systematic troubleshooting process, I:

- Verified the temperature sensor readings: Confirmed that the sensor was functioning correctly and providing accurate temperature data.

- Inspected the control loop: Checked the wiring, connections, and controller parameters to ensure proper communication and signal integrity.

- Monitored the system dynamics: Used a data logger to capture temperature data over time and identify any patterns or anomalies.

- Identified a faulty actuator: Determined that the actuator responsible for adjusting the control valve was malfunctioning intermittently.

- Replaced the actuator: Swapped out the faulty actuator with a new one and observed a significant improvement in temperature control.

8. What is your experience with using computerized maintenance management systems (CMMS)?

I have extensive experience using CMMS, such as [CMMS name], for managing preventive maintenance tasks, equipment inventories, and work orders. I am proficient in:

- Scheduling and tracking preventive maintenance inspections.

- Generating work orders and assigning technicians.

- Uploading inspection reports and maintenance records.

- Analyzing maintenance data to identify trends and improve maintenance strategies.

- Customizing the CMMS to meet specific facility or equipment requirements.

9. How do you collaborate with maintenance teams to ensure effective and timely repairs?

I work closely with maintenance teams to ensure efficient coordination and execution of repairs. My approach involves:

- Clear communication: Regularly communicating with maintenance technicians to discuss maintenance schedules, findings, and recommendations.

- Prioritization of repairs: Collaborating with maintenance managers to prioritize repairs based on criticality, risk, and potential impact on operations.

- Providing technical guidance: Offering technical advice and support to maintenance technicians during troubleshooting and repairs.

- Follow-up inspections: Conducting follow-up inspections to verify the effectiveness of repairs and ensure optimal equipment performance.

- Continuous improvement: Regularly reviewing maintenance processes with maintenance teams to identify areas for improvement and collaboration.

10. How do you handle situations where you encounter equipment that is not operating within specifications?

When I encounter equipment that is not operating within specifications, I follow these steps:

- Thorough inspection: Inspect the equipment to identify any obvious issues, such as loose connections, damaged components, or incorrect settings.

- Troubleshooting: Use diagnostic tools and techniques to isolate the source of the problem.

- Repair or maintenance: Perform necessary repairs or maintenance to restore the equipment to proper functionality.

- Verification: Test the equipment to ensure that it is operating within specifications after the repair or maintenance.

- Documentation: Document the findings, actions taken, and any recommendations for further maintenance or monitoring.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrumentation and Electrical Preventive Maintenance Inspector IE PM Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrumentation and Electrical Preventive Maintenance Inspector IE PM Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Instrumentation and Electrical Preventive Maintenance Inspectors, IE PM Inspectors, play a critical role in ensuring the smooth and efficient operation of industrial and commercial facilities. Their key responsibilities include:

1. Preventive Maintenance Inspection

Conducting regular preventive maintenance inspections of instrumentation and electrical systems, including equipment such as sensors, transmitters, controllers, motors, and transformers.

2. Troubleshooting and Repair

Identifying and diagnosing faults in instrumentation and electrical systems. Carrying out necessary repairs and replacements to restore equipment to optimal condition.

3. Calibration and Verification

Calibrating and verifying the accuracy of instrumentation devices, ensuring they meet industry standards and specifications.

4. Documentation and Reporting

Maintaining detailed records of inspections, repairs, and calibrations. Reporting any issues or irregularities to the relevant authorities.

Interview Tips

Preparing thoroughly for an interview is crucial for success. Here are some tips and hacks to help candidates ace their interview for an IE PM Inspector role:

1. Research the Company and Role

Familiarize yourself with the company’s industry, operations, and the specific requirements of the IE PM Inspector position.

2. Prepare Answers to Common Interview Questions

Practice your responses to common interview questions, such as “Tell me about your experience in preventive maintenance,” “What are your strengths and weaknesses as an IE PM Inspector?”, and “Why are you interested in this role?”

- Example Outline: “In my previous role as an IE PM Inspector, I was responsible for inspecting and maintaining a wide range of instrumentation and electrical systems. My key responsibilities included conducting preventive maintenance inspections, troubleshooting and repairing faults, and calibrating and verifying the accuracy of instrumentation devices. I have a strong understanding of industry standards and regulations, and I am proficient in using various test and measurement equipment.”

3. Highlight Your Skills and Experience

During the interview, emphasize your technical skills, experience in preventive maintenance, and your ability to work independently and as part of a team.

- Example: “Throughout my career as an IE PM Inspector, I have developed a comprehensive skill set that includes the ability to conduct thorough inspections, diagnose complex issues, and perform repairs efficiently. I am also skilled in using various calibration and testing equipment, including multimeters, oscilloscopes, and calibration standards.”

4. Ask Questions

Asking insightful questions at the end of the interview demonstrates your engagement and interest in the role. Ask about the company’s safety policies, the training and development opportunities available, and the team you will be working with.

- Example: “I am particularly interested in the company’s commitment to safety. Could you please elaborate on the safety policies and procedures in place for IE PM Inspectors?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Instrumentation and Electrical Preventive Maintenance Inspector IE PM Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.