Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Insulation Applicator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

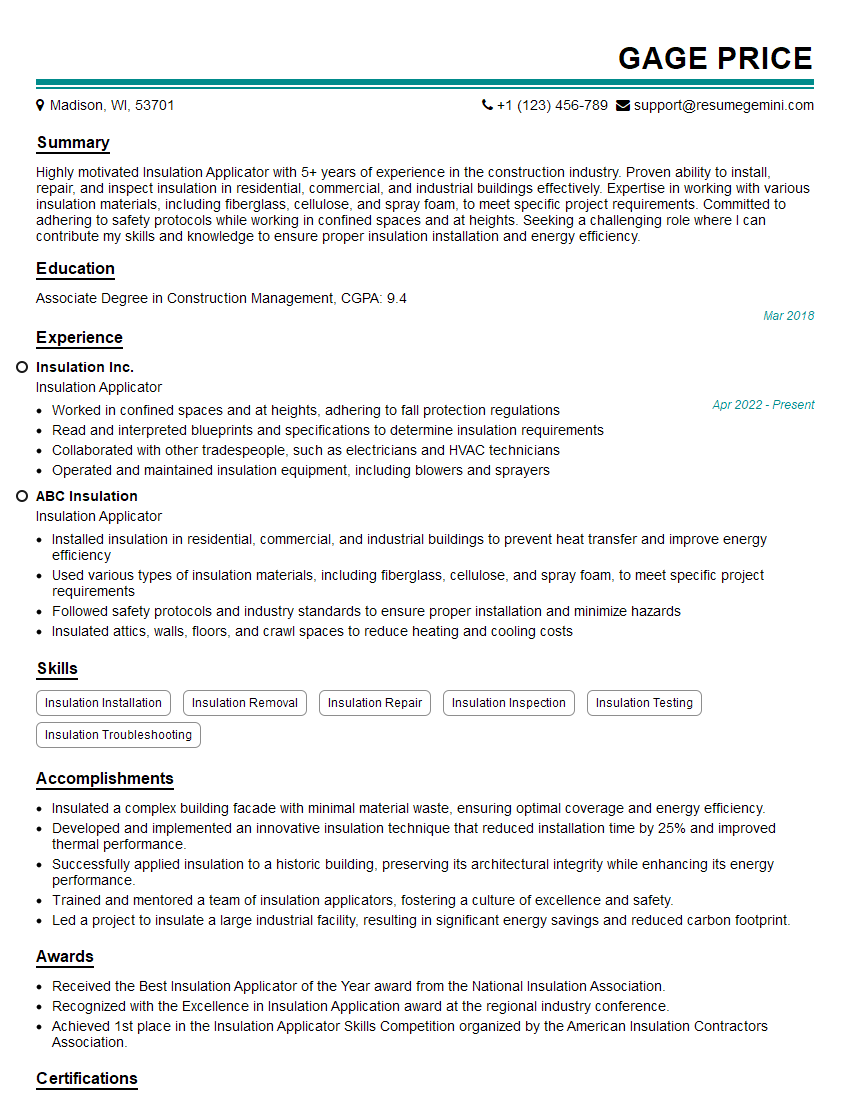

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Insulation Applicator

1. What are the different types of insulation materials you have experience working with?

As an Insulation Applicator, I have hands-on experience working with a wide range of insulation materials, including:

- Fiberglass batts and rolls

- Cellulose insulation

- Spray foam insulation

- Rigid foam boards

- Loose-fill insulation, such as vermiculite and perlite

2. Can you describe the different insulation installation techniques you are familiar with?

Blown-in Insulation

- Using specialized equipment to blow loose-fill insulation into attics, walls, and other cavities.

- Ensuring even coverage and proper density to maximize insulation performance.

Batt and Roll Insulation

- Cutting and fitting fiberglass or cellulose batts and rolls to fit snugly within wall cavities, attics, and crawl spaces.

- Stapling or nailing batts in place to secure them and prevent air infiltration.

Spray Foam Insulation

- Applying liquid spray foam insulation to surfaces using specialized equipment.

- Controlling the thickness and coverage to achieve desired insulation values and air sealing.

3. What safety precautions should be taken when working with insulation materials?

I prioritize safety when working with insulation materials by adhering to the following precautions:

- Wearing appropriate personal protective equipment (PPE), including gloves, safety glasses, and respirators.

- Handling insulation materials carefully to avoid dust inhalation or skin irritation.

- Following proper ventilation guidelines to prevent the buildup of harmful fumes or gases.

- Storing insulation materials in a dry and well-ventilated area to prevent moisture damage or mold growth.

4. How do you calculate the R-value of insulation materials?

To calculate the R-value of insulation materials, I follow these steps:

- Determine the material’s thermal conductivity (k-value), which measures its resistance to heat flow.

- Divide the material’s thickness by its k-value.

- The result is the R-value, which represents the material’s ability to resist heat transfer.

5. What factors should be considered when selecting insulation materials for a specific application?

When selecting insulation materials, I consider several key factors:

- Climate and local building codes: Insulation choices should align with the climate zone and meet building code requirements for thermal performance.

- Type of construction: The insulation material should be compatible with the building’s structure and construction methods.

- Desired R-value: The insulation’s R-value should meet or exceed the target insulation value for the project.

- Cost and availability: The cost and availability of different insulation materials should be taken into account.

6. How do you inspect and evaluate existing insulation systems?

To inspect and evaluate existing insulation systems, I follow a thorough process:

- Visual inspection: Checking for signs of damage, moisture, or gaps in the insulation.

- Thermal imaging: Using a thermal camera to identify areas of heat loss or insufficient insulation.

- R-value testing: Conducting tests to measure the insulation’s actual R-value and compare it to the expected value.

- Moisture testing: Using moisture meters to detect any moisture buildup within the insulation.

7. What techniques do you use to air seal insulation systems and prevent air infiltration?

To effectively air seal insulation systems and prevent air infiltration, I employ the following techniques:

- Caulking and sealing: Using caulk, sealants, and weatherstripping to seal gaps and cracks around windows, doors, and other openings.

- Foam insulation: Applying spray foam insulation to fill gaps and crevices, creating an airtight barrier.

- House wrap: Installing house wrap, a moisture-resistant and air-impermeable material, around the exterior of the building to prevent air infiltration.

8. How do you stay up-to-date on the latest insulation materials and techniques?

To stay informed about the latest insulation materials and techniques, I actively engage in the following practices:

- Industry conferences and workshops: Attending industry events to learn about new products and best practices.

- Trade publications and online resources: Reading industry magazines, articles, and online forums to stay abreast of technological advancements.

- Manufacturer training: Participating in training programs offered by insulation manufacturers to learn about their latest products and installation methods.

9. What quality control measures do you implement to ensure the proper installation of insulation systems?

To ensure the proper installation of insulation systems and maintain high-quality standards, I implement the following quality control measures:

- Material inspection: Inspecting insulation materials upon delivery to ensure they meet specifications and are free from damage.

- Installation verification: Checking that insulation is installed according to manufacturer’s instructions and industry best practices.

- Thermal imaging: Using thermal imaging to identify areas where insulation may be insufficient or improperly installed.

- Regular maintenance: Providing ongoing maintenance and inspection services to ensure that insulation systems continue to perform optimally.

10. How do you handle unexpected challenges or issues that arise during insulation installation?

When faced with unexpected challenges or issues during insulation installation, I approach them with the following strategies:

- Problem identification: Thoroughly assessing the situation to identify the root cause of the issue.

- Research and consultation: Consulting with colleagues, manufacturers, or industry experts to explore possible solutions.

- Alternative solutions: Developing and implementing alternative insulation approaches or techniques to address the challenge effectively.

- Communication: Keeping all stakeholders informed about the issue and the steps taken to resolve it.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Insulation Applicator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Insulation Applicator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Insulation Applicator is a professional who specializes in the installation and maintenance of insulation materials in residential, commercial, and industrial buildings. Their key job responsibilities typically include:

1. Insulation Installation

Installing various types of insulation materials, including fiberglass, cellulose, and spray foam, in accordance with building codes and industry standards.

- Determining insulation requirements based on building specifications and energy efficiency regulations.

- Preparing surfaces by removing old insulation, cleaning, and repairing any damaged areas.

2. Insulation Maintenance and Repair

Inspecting existing insulation for damage or deterioration and performing necessary repairs or replacements.

- Identifying and addressing factors that may compromise insulation performance, such as moisture, pests, or air leaks.

- Repairing or replacing damaged insulation to ensure optimal thermal performance and energy efficiency.

3. Material Handling and Equipment Use

Handling and transporting insulation materials safely and efficiently, using appropriate equipment and tools.

- Operating and maintaining insulation application equipment, such as sprayers, blowers, and cutting machines.

- Following safety protocols for handling insulation materials, including proper ventilation and protective gear.

4. Communication and Collaboration

Collaborating with other construction professionals, such as architects, engineers, and contractors.

- Communicating insulation requirements and installation plans to ensure coordination and compliance.

- Providing advice and guidance to homeowners or business owners on insulation options and energy efficiency.

Interview Tips

Preparing thoroughly for an Insulation Applicator interview can significantly increase your chances of success. Here are some key tips and hacks to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s website, social media profiles, and industry publications to gain insights into their business practices, values, and industry trends.

- Demonstrating your knowledge of the company and industry shows your interest and enthusiasm.

- Use specific examples from your research to support your answers during the interview.

2. Prepare for Technical Questions

Expect questions about insulation materials, installation techniques, and industry standards. Practice answering questions related to:

- Different types of insulation materials and their applications.

- Building codes and industry regulations for insulation installation.

- Troubleshooting and resolving common insulation issues.

3. Highlight Your Skills and Experience

Showcase your relevant skills and experience by providing examples from your previous work. Quantify your accomplishments whenever possible using specific metrics.

- Emphasize your proficiency in insulation installation techniques and equipment.

- Highlight your ability to analyze insulation needs and recommend appropriate solutions.

- Provide examples of successful projects where you ensured energy efficiency and customer satisfaction.

4. Practice Common Interview Questions

Prepare answers to common interview questions, such as:

- Tell me about yourself and your experience in insulation.

- Why are you interested in this position?

- What are your strengths and weaknesses as an Insulation Applicator?

- How do you stay up-to-date with industry trends and best practices?

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions to demonstrate your engagement and interest in the position. Consider asking about:

- The company’s commitment to sustainability and energy efficiency.

- Opportunities for professional development and advancement.

- The company’s culture and work environment.

Asking thoughtful questions shows that you are genuinely interested in the position and the company, and that you are actively considering your fit within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Insulation Applicator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!