Feeling lost in a sea of interview questions? Landed that dream interview for Insulation Blanket Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Insulation Blanket Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

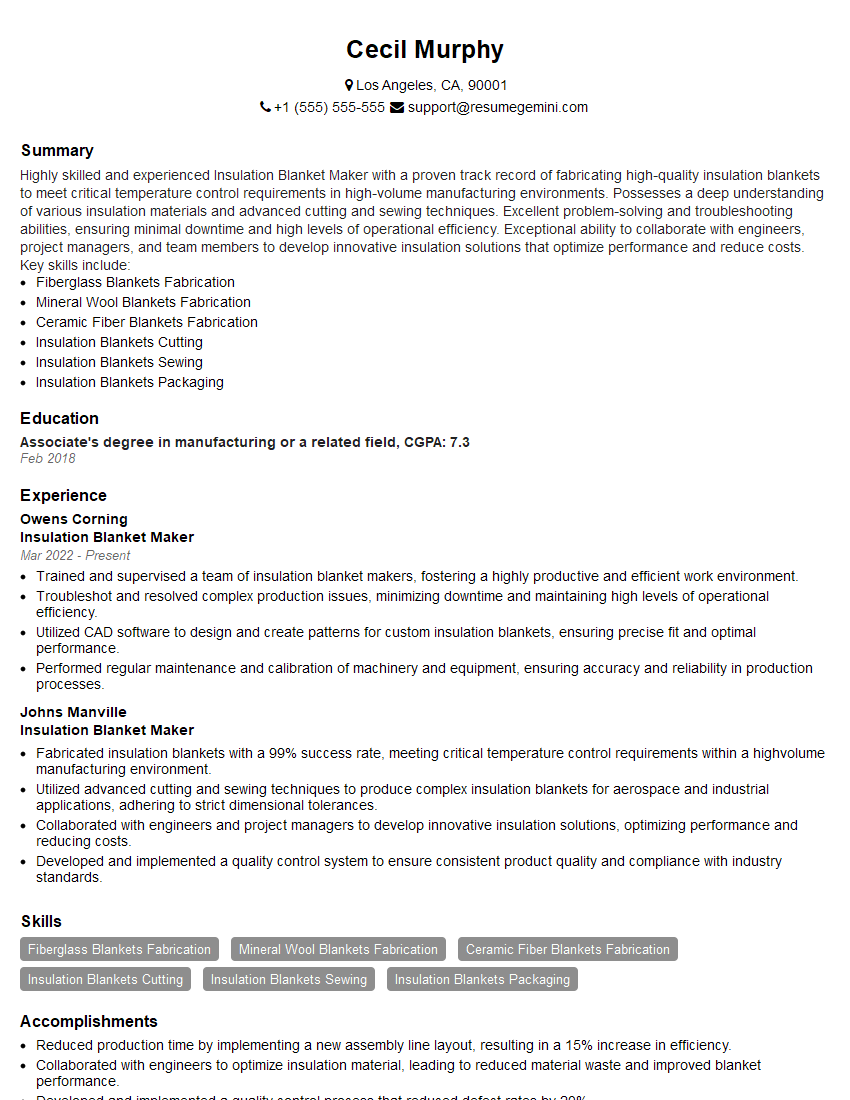

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Insulation Blanket Maker

1. What is the primary purpose of using insulation blankets in industrial applications?

Insulation blankets are crucial in industrial settings for several reasons:

- Temperature control: They help regulate temperature by preventing heat loss or gain, thus ensuring optimal operating conditions for equipment and processes.

- Energy efficiency: By minimizing heat transfer, insulation blankets reduce energy consumption and lower operating costs.

2. What are the key types of insulation materials used in blanket manufacturing, and how do they differ in performance?

Glass wool

- Pros: Lightweight, cost-effective, and flame-resistant.

- Cons: Can absorb moisture, requiring proper encapsulation.

Rock wool

- Pros: Excellent thermal resistance, fire-resistant, and durable.

- Cons: Denser than glass wool, making it heavier and more expensive.

Mineral wool

- Pros: Non-combustible, sound-absorbing, and moisture-resistant.

- Cons: More expensive than other materials and requires specialized installation techniques.

3. Describe the process of fabricating insulation blankets, including material preparation, cutting, and assembly.

The insulation blanket fabrication process typically involves the following steps:

- Material preparation: The insulation material is cut into sheets or rolls according to design specifications.

- Cutting: The sheets or rolls are cut to the desired shapes and sizes using automated or manual cutting machines.

- Assembly: The cut pieces are assembled together using adhesives, stitching, or other techniques to form the final blanket.

4. What are the critical quality control measures implemented during insulation blanket production?

Rigorous quality control measures are essential to ensure the performance and reliability of insulation blankets:

- Material inspection: Raw materials are inspected for defects and compliance with specifications.

- Dimensional accuracy: Blankets are checked for size, shape, and thickness to meet design requirements.

- Thermal performance testing: Blankets undergo testing to verify their thermal resistance and insulation properties.

5. Discuss the factors that influence the cost of insulation blankets, such as material selection, size, and complexity.

The cost of insulation blankets is influenced by several factors:

- Material selection: Different insulation materials vary in cost based on their properties and availability.

- Size and thickness: Larger and thicker blankets require more material and labor, leading to higher costs.

- Complexity: Blankets with intricate shapes or multiple layers can be more complex and expensive to manufacture.

6. How do you determine the appropriate thickness and R-value of insulation blankets for specific applications?

The thickness and R-value of insulation blankets are determined based on several factors:

- Heat loss calculations: Thermal calculations are performed to determine the required heat loss reduction.

- Equipment temperature requirements: Insulation thickness ensures the equipment operates within its optimal temperature range.

- Environmental conditions: Factors such as ambient temperature and wind speed influence the insulation requirements.

7. What are the safety precautions to consider when working with insulation blankets?

Handling insulation blankets requires adherence to safety measures:

- Wear appropriate PPE: Safety glasses, gloves, and respirators should be used to protect against dust and fibers.

- Avoid skin contact: Insulation fibers can irritate skin; proper clothing and gloves should be worn.

- Control dust exposure: Dust masks or respirators should be used to minimize inhalation of insulation fibers.

8. How do you stay updated on the latest advancements and best practices in insulation blanket technology?

To stay informed about advancements and best practices, I engage in the following activities:

- Attend industry conferences and workshops: These events provide opportunities to learn from experts and network with professionals.

- Read industry publications and research papers: I regularly review technical journals and articles to stay abreast of new technologies and research findings.

- Consult with suppliers and manufacturers: I collaborate with suppliers to gain insights into the latest product innovations and industry trends.

9. Can you describe a challenging project you encountered while working with insulation blankets, and how you resolved it?

In a previous project, I encountered a situation where the insulation blanket was not meeting the required R-value specifications. To address this issue, I conducted thorough material testing and identified the source of the discrepancy.

- Material testing: I tested the insulation material for density, thickness, and thermal conductivity to pinpoint the cause of the performance issue.

- Corrective actions: Based on the test results, I worked with the supplier to adjust the manufacturing process to ensure the blankets met the required specifications.

- Successful implementation: The corrected insulation blankets were installed, and the system achieved the desired thermal performance.

10. How do you ensure the durability and longevity of insulation blankets in demanding industrial environments?

To ensure durability and longevity, I take the following measures:

- Use high-quality materials: Selecting durable materials such as high-temperature fabrics and reinforced stitching enhances the blanket’s ability to withstand harsh conditions.

- Proper installation: Correct installation techniques, including secure anchoring and minimizing stress points, prevent damage and extend the blanket’s lifespan.

- Regular maintenance: Scheduled inspections and maintenance can identify potential issues early on, allowing for timely repairs and replacements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Insulation Blanket Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Insulation Blanket Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Insulation Blanket Makers are responsible for creating thermal insulation blankets used in various industries, including construction, manufacturing, and aerospace.

1. Raw Material Preparation

Prepare raw materials such as fiberglass, mineral wool, or other insulating materials.

- Mix and blend materials according to specifications.

- Cut and shape materials to create insulation blankets.

2. Fabrication and Assembly

Assemble insulation blankets using adhesives, stitching, or other techniques.

- Ensure proper fit and performance of blankets.

- Inspect blankets for any defects or imperfections.

3. Quality Control and Testing

Conduct quality control checks and testing to ensure blankets meet specifications.

- Test insulation properties, such as thermal resistance and fire resistance.

- Maintain documentation and records of quality control measures.

4. Production and Efficiency

Monitor production processes and strive for efficiency.

- Optimize material usage and minimize waste.

- Troubleshoot production issues and implement corrective actions.

Interview Tips

Preparation is key to acing any job interview. Here are some tips and hacks to help you prepare for an Insulation Blanket Maker interview:

1. Research the Company and Role

Research the company’s website, LinkedIn profile, and industry news to gain insights into their values, culture, and the specific role you’re applying for.

- Identify the company’s products, services, and target market.

- Learn about the specific insulation blanket products they manufacture.

2. Practice Your Answers

Prepare and practice answers to common interview questions. Anticipate questions about your experience, skills, and why you’re interested in the position.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Quantify your accomplishments with specific examples and metrics.

3. Highlight Your Technical Skills

Emphasize your technical skills in insulation blanket manufacturing, such as experience with different types of insulating materials, fabrication techniques, and testing procedures.

- Discuss your understanding of insulation properties and industry standards.

- Showcase your knowledge of production processes and quality control measures.

4. Demonstrate Your Attention to Detail

Insulation Blanket Makers require meticulous attention to detail, so highlight your ability to work accurately and effectively.

- Mention any experience you have with quality assurance, inspection, or precision manufacturing.

- Emphasize your ability to follow instructions and meet specifications.

Next Step:

Now that you’re armed with the knowledge of Insulation Blanket Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Insulation Blanket Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini