Are you gearing up for an interview for a Insulator Tester position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Insulator Tester and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

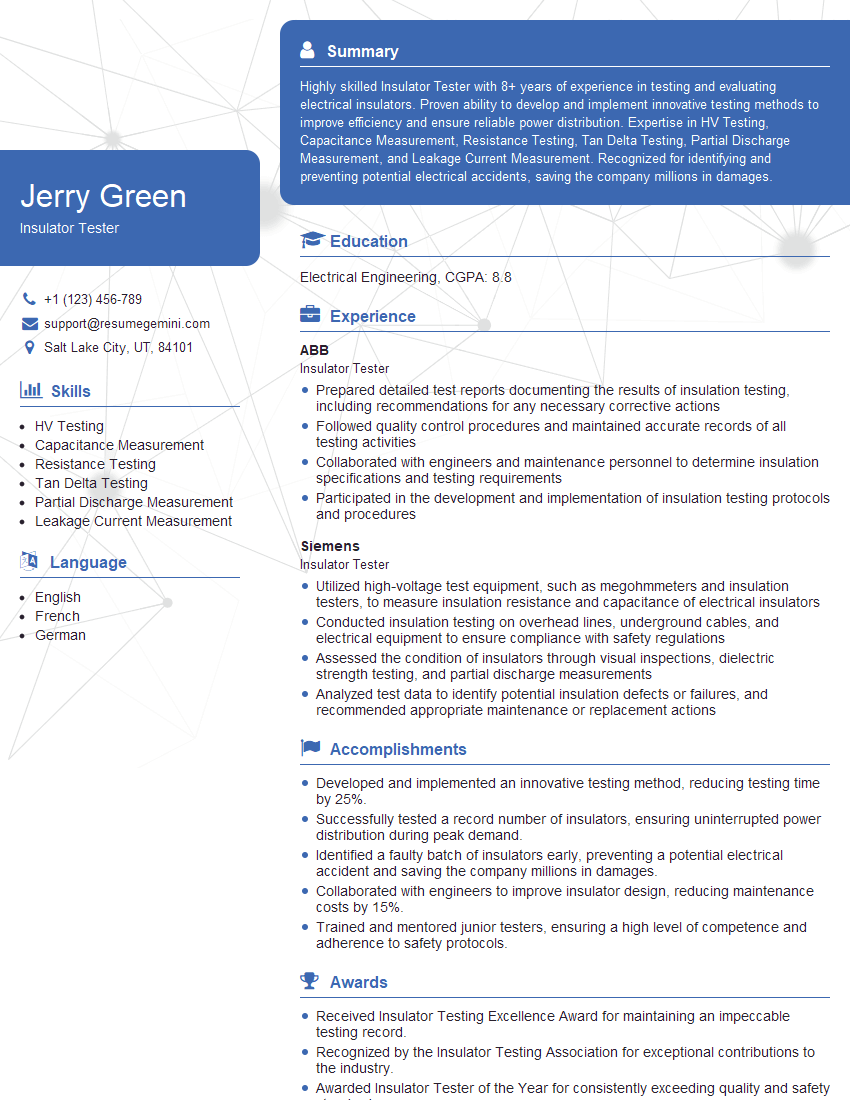

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Insulator Tester

1. What are the different types of insulator testers and how do they work?

There are two main types of insulator testers: AC and DC. AC testers apply a high-voltage AC signal to the insulator, and DC testers apply a high-voltage DC signal. Both types of testers measure the current that flows through the insulator, and the amount of current that flows indicates the condition of the insulator.

- AC testers are typically used to test insulators that are in service, as they can be applied to live lines. AC testers are also less expensive than DC testers.

- DC testers are typically used to test insulators that are not in service, as they can provide a more accurate measurement of the insulator’s condition. DC testers are also more expensive than AC testers.

2. What are the safety precautions that must be taken when testing insulators?

When testing insulators, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including rubber gloves, safety glasses, and a hard hat.

- Use a properly grounded tester, and make sure that the test leads are in good condition.

- Do not touch the insulator while it is being tested, and do not allow anyone else to touch the insulator.

- Keep the test area clear of people and animals, and post warning signs to prevent anyone from entering the area.

- Follow the manufacturer’s instructions for the tester, and do not exceed the rated voltage of the tester.

3. How do you interpret the results of an insulator test?

The results of an insulator test can be interpreted to determine the condition of the insulator. The following are some general guidelines:

- A high current reading indicates that the insulator is in good condition. The current should be within the manufacturer’s specified range.

- A low current reading indicates that the insulator is in poor condition. The insulator may be cracked, chipped, or contaminated.

- A zero current reading indicates that the insulator is completely failed. The insulator must be replaced.

4. What are the different types of insulators and what are their applications?

There are many different types of insulators, each with its own unique properties and applications. The following are some of the most common types of insulators:

- Porcelain insulators are made of a high-voltage ceramic material. They are strong and durable, and they can withstand high temperatures. Porcelain insulators are commonly used in power transmission lines.

- Glass insulators are made of a high-voltage glass material. They are less strong than porcelain insulators, but they are also less expensive. Glass insulators are commonly used in distribution lines.

- Composite insulators are made of a combination of materials, such as fiberglass, epoxy, and silicone. They are lightweight and durable, and they can withstand high voltages. Composite insulators are commonly used in high-voltage transmission lines.

5. What are the factors that can affect the life of an insulator?

The life of an insulator can be affected by a number of factors, including

- The type of insulator – Some insulators are more durable than others.

- The operating conditions – Insulators that are exposed to high temperatures, high humidity, or pollution will have a shorter life expectancy.

- The maintenance practices – Insulators that are not properly maintained will have a shorter life expectancy.

6. What are the signs of insulator failure?

The following are some of the signs of insulator failure:

- Cracks or chips in the insulator

- Discoloration of the insulator

- A low current reading on an insulator test

- A high current reading on an insulator test

- A zero current reading on an insulator test

7. What are the consequences of insulator failure?

Insulator failure can have a number of consequences, including:

- Power outages

- Equipment damage

- Fire

- Personal injury

8. How can insulator failure be prevented?

Insulator failure can be prevented by taking the following steps:

- Properly selecting the insulator for the application

- Properly installing the insulator

- Properly maintaining the insulator

- Regularly testing the insulator

9. What are the latest trends in insulator technology?

The latest trends in insulator technology include:

- The use of composite materials – Composite materials are lighter and more durable than traditional materials, and they can withstand higher voltages.

- The use of nanotechnology – Nanotechnology is being used to develop new materials and coatings that can improve the performance of insulators.

- The use of smart technology – Smart technology is being used to develop insulators that can monitor their own condition and report any problems.

10. What is the future of insulator technology?

The future of insulator technology is bright. The development of new materials, coatings, and technologies is making insulators more efficient, durable, and reliable. Insulators are essential to the safe and efficient operation of the power grid, and they will continue to play an important role in the future.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Insulator Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Insulator Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An insulator tester plays a crucial role in the electrical industry, ensuring the safety and reliability of electrical equipment and systems. The key job responsibilities typically include the following:

1. Testing Insulation Resistance

Using various testing devices, an insulator tester measures the resistance of electrical insulators to ensure they meet specified standards. This involves conducting tests on transformers, switchgears, cables, and other components to assess their ability to withstand electrical stress and prevent current leakage.

- Perform insulation resistance tests on high-voltage equipment, such as transformers, bushings, and circuit breakers.

- Analyze test results and interpret data to identify potential insulation problems and make recommendations for repairs or replacements.

2. Evaluating Insulator Performance

The tester evaluates the performance of insulators in different operating conditions, such as exposure to moisture, temperature fluctuations, and mechanical stress. This involves conducting visual inspections, analyzing maintenance records, and assessing insulation degradation levels to ensure the ongoing integrity and safety of electrical installations.

- Inspect insulators for signs of damage, such as cracks, chips, or discoloration.

- Monitor insulator performance over time by tracking maintenance records and environmental conditions.

3. Troubleshooting and Problem Solving

When insulation-related issues arise, the tester troubleshoots and resolves problems to restore electrical system functionality and safety. This involves analyzing test results, identifying fault locations, and implementing corrective measures to address insulation failures or inefficiencies.

- Troubleshoot insulation failures and identify the root cause of problems.

- Recommend and implement corrective actions to repair or replace faulty insulators.

4. Maintaining Test Equipment

An insulator tester maintains and calibrates testing equipment to ensure accuracy and reliability. This involves performing regular inspections, conducting preventive maintenance, and adhering to manufacturer specifications to ensure the integrity of test results.

- Calibrate and maintain insulation testing equipment according to manufacturer’s specifications.

- Troubleshoot and repair testing equipment as needed.

Interview Tips

Preparing thoroughly for an insulator tester interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company you’re applying to and the specific insulator tester position. Understanding the company’s values, mission, and industry reputation will help you tailor your answers to demonstrate your alignment with the organization’s goals.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about the latest trends and technologies.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers beforehand. This will help you articulate your skills and experience clearly and confidently during the interview. Focus on highlighting your technical abilities, problem-solving capabilities, and commitment to safety.

- Prepare answers to questions about your experience with insulation testing, troubleshooting, and equipment maintenance.

- Practice describing your understanding of electrical safety regulations and industry standards.

3. Highlight Your Relevant Skills and Experience

During the interview, make sure to emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate the impact of your work. Use specific examples to illustrate your abilities and how you have contributed to successful outcomes.

- Provide examples of projects where you successfully identified and resolved insulation-related issues.

- Quantify your achievements, such as reducing equipment downtime or improving safety outcomes.

4. Ask Thoughtful Questions

Asking insightful questions at the end of the interview demonstrates your interest and engagement. Prepare questions that delve into the company’s culture, growth opportunities, and commitment to professional development. This shows that you’re genuinely interested in the position and the company’s values.

- Ask about the company’s approach to safety and training.

- Inquire about opportunities for professional growth and advancement within the organization.

5. Be Professional and Enthusiastic

Throughout the interview, maintain a professional demeanor and demonstrate enthusiasm for the position. Dress appropriately, arrive on time, and be respectful of the interviewer’s time. Your positive attitude and eagerness to learn will leave a lasting impression.

- Dress professionally and maintain good posture during the interview.

- Be polite and respectful to the interviewer and other staff you encounter.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Insulator Tester interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.