Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Integrated Circuit Fabricator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Integrated Circuit Fabricator so you can tailor your answers to impress potential employers.

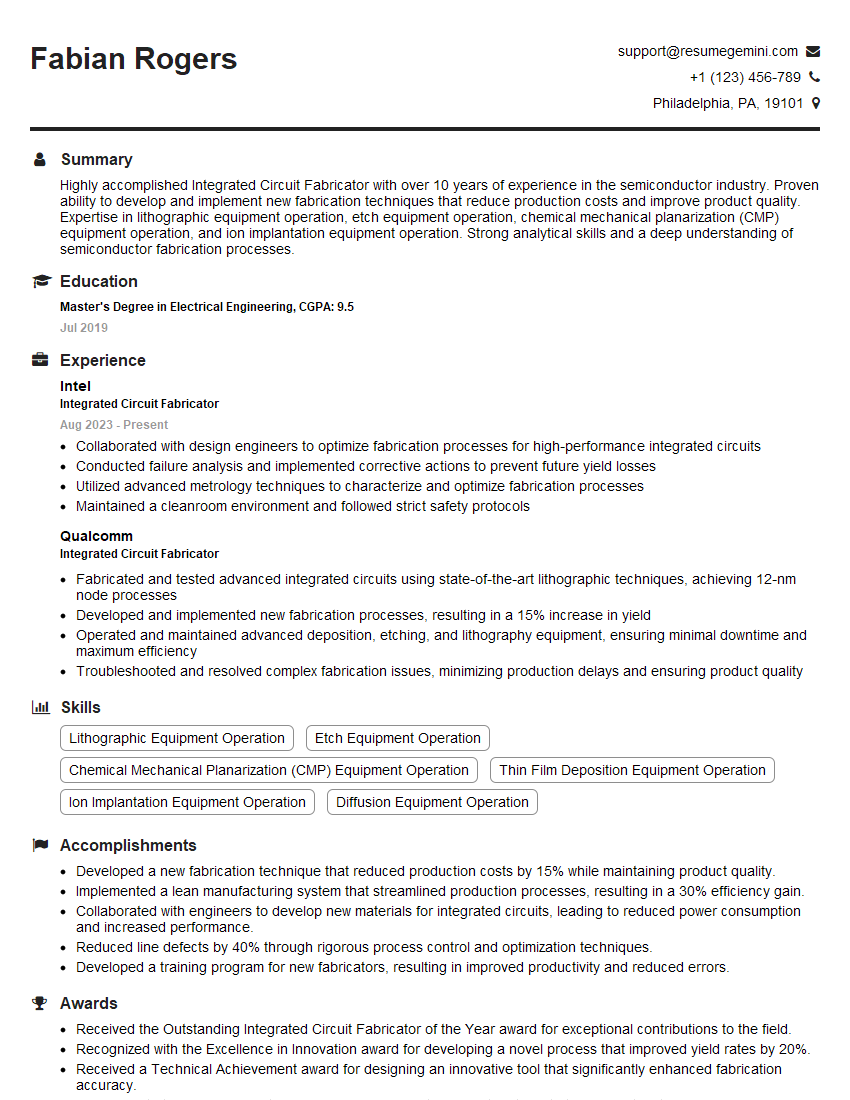

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Integrated Circuit Fabricator

1. Explain the role of photolithography in integrated circuit fabrication.

Photolithography is a fundamental technique in integrated circuit fabrication used to create patterns on the surface of a semiconductor wafer. It involves the following steps:

- Create a Photoresist Mask: A photoresist is applied to the wafer, and a mask is used to expose specific areas of the photoresist to ultraviolet (UV) light.

- Develop the Mask: The exposed areas of the photoresist become hardened, while the unexposed areas are washed away, creating a pattern on the wafer.

- Etching: The unprotected areas of the wafer are then etched, transferring the pattern to the underlying material.

2. Discuss the key steps involved in chemical vapor deposition (CVD).

Substrate Preparation

- Clean the substrate to remove contaminants.

- Apply a thin adhesion layer to enhance film adhesion.

Gas Delivery

- Introduce precursor gases into a reaction chamber.

- Control gas flow rates and ratios to achieve desired deposition characteristics.

Deposition

- Chemical reactions occur between precursor gases and the substrate surface.

- Atoms or molecules are deposited on the substrate, forming a thin film.

3. Describe the difference between a wet etch and a dry etch.

- Wet Etch: Uses liquid etchants to chemically dissolve the material. It is isotropic, etching in all directions equally.

- Dry Etch: Uses plasma or reactive gases to bombard the surface with ions or atoms. It is anisotropic, etching vertically or in a specific direction.

4. Explain the purpose of ion implantation in semiconductor fabrication.

- Implant ions of a specific dopant type (e.g., boron, phosphorus) into the semiconductor material.

- Precisely control the concentration and depth of dopant atoms, influencing the electrical properties of the material.

- Create regions with different conductivity (n-type or p-type) for building transistor structures.

5. What are the challenges associated with the integration of three-dimensional (3D) structures in integrated circuits?

- Complex Fabrication: Patterning and deposition processes become more challenging in 3D, requiring specialized techniques.

- Thermal Management: Heat dissipation becomes a concern as 3D structures increase device density.

- Interconnect Complexity: Connecting 3D structures requires novel interconnect technologies to maintain signal integrity.

- Design Complexity: Designing 3D integrated circuits requires advanced modeling and simulation tools.

6. How do you ensure quality control in integrated circuit fabrication?

- Process Monitoring: Regularly monitoring process parameters (e.g., temperature, pressure, deposition rate) to maintain process stability.

- Statistical Process Control (SPC): Statistical techniques to identify and eliminate process variations.

- Wafer Inspection: Using automated optical or electron microscopy to detect defects on wafers.

- Reliability Testing: Electrical, thermal, and stress testing to ensure that fabricated circuits meet performance specifications.

7. Discuss the role of cleanrooms in semiconductor manufacturing.

- Contamination Control: Maintain a controlled environment with minimal airborne particles, humidity, and temperature to prevent contamination of wafers.

- Equipment Maintenance: Ensure that all equipment in the cleanroom is well-maintained and calibrated to meet process requirements.

- Training and Garbing: Proper training and protective gear (e.g., gowns, gloves, masks) are essential to minimize contamination.

8. What are the recent advancements in integrated circuit packaging technology?

- Advanced Packaging: Chip-on-wafer (CoW) and 2.5D/3D packaging to enhance device performance and reduce size.

- High-Density Interconnects: Embedded via interconnects and microbumps for improved signal integrity and reduced parasitics.

- Heterogeneous Integration: Combining different types of semiconductor devices (e.g., CMOS, memory) in a single package.

9. What emerging materials are being used in integrated circuit fabrication?

- Novel Semiconductors: Silicon carbide (SiC), gallium nitride (GaN) for high-power and high-frequency applications.

- Two-Dimensional Materials: Graphene, transition metal dichalcogenides for low-power and flexible electronics.

- Biocompatible Materials: Conducting polymers, hydrogels for medical devices and sensor applications.

10. How does the use of artificial intelligence (AI) impact integrated circuit fabrication?

- Process Optimization: AI algorithms can analyze large amounts of data to identify and optimize process parameters for better yield and performance.

- Defect Detection: AI-based machine learning can automate defect detection in wafers, reducing inspection time and cost.

- Predictive Maintenance: AI can monitor equipment data to predict and prevent failures, minimizing downtime.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Integrated Circuit Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Integrated Circuit Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Integrated Circuit Fabricator is accountable for producing and maintaining integrated circuits (ICs), the essential components found in electronic devices. This role plays a critical part in the electronics industry and demands technical expertise and precision in manufacturing.

1. IC Fabrication

The primary responsibility involves fabricating ICs following established processes and design specifications. This includes:

- Depositing thin films of materials onto silicon wafers using techniques like chemical vapor deposition (CVD) and physical vapor deposition (PVD).

- Patterning circuits onto wafers using lithography and etching techniques.

- Performing photolithography to create intricate circuit patterns.

- Connecting components through metallization processes such as sputtering and electroplating.

2. Process Control and Optimization

To ensure the quality and efficiency of IC fabrication, Integrated Circuit Fabricators monitor and optimize production processes:

- Analyzing process parameters and making adjustments to improve yield and minimize defects.

- Performing statistical process control (SPC) to identify and eliminate sources of variation.

- Collaborating with engineers and technicians to identify and resolve production issues.

3. Equipment Maintenance and Troubleshooting

Maintaining and troubleshooting equipment is essential for smooth production:

- Inspecting and calibrating equipment regularly to ensure accuracy and precision.

- Performing preventative maintenance tasks to minimize downtime and extend equipment life.

- Diagnosing and resolving equipment malfunctions promptly to minimize production disruptions.

4. Quality Control and Testing

Ensuring the quality of ICs is crucial. Integrated Circuit Fabricators:

- Conducting electrical and functional testing of ICs to verify their performance against specifications.

- Analyzing test results to identify and correct any defects or non-conformances.

- Maintaining documentation and records related to quality control procedures.

Interview Tips

To excel in an Integrated Circuit Fabricator interview, preparation is key. Here are some valuable tips to help you ace the interview:

1. Research the Company and Role

Demonstrate your interest in the company by thoroughly researching their products, services, and industry standing. Familiarize yourself with the specific role and its responsibilities to articulate how your skills align.

2. Highlight Technical Expertise

Emphasize your technical knowledge and experience in IC fabrication processes. Showcase your understanding of semiconductor physics, materials science, and fabrication techniques. Provide specific examples of projects or assignments that demonstrate your proficiency.

3. Showcase Analytical and Problem-Solving Skills

Highlight your ability to analyze data, troubleshoot problems, and find solutions in a fast-paced manufacturing environment. Share instances where you identified and resolved production issues, optimized processes, or improved product quality.

4. Emphasize Quality and Precision

Convey your commitment to producing high-quality ICs. Discuss your experience in quality control and testing procedures. Explain how you ensure accuracy and precision in your work.

5. Prepare for Technical Questions

Anticipate technical questions related to IC fabrication, such as:

- Describe the process of photolithography and its role in IC manufacturing.

- Explain how different etching techniques are used to create specific circuit patterns.

- Discuss the importance of process control and optimization in IC fabrication.

6. Practice Your Communication Skills

Effective communication is vital in any interview. Practice articulating your thoughts clearly and concisely. Focus on providing specific examples and quantifying your accomplishments whenever possible.

7. Dress Professionally and Arrive Punctually

Demonstrate your professionalism by dressing appropriately for the interview and arriving on time. Punctuality shows respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Integrated Circuit Fabricator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!