Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Interlocking Concrete Pavement Installer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

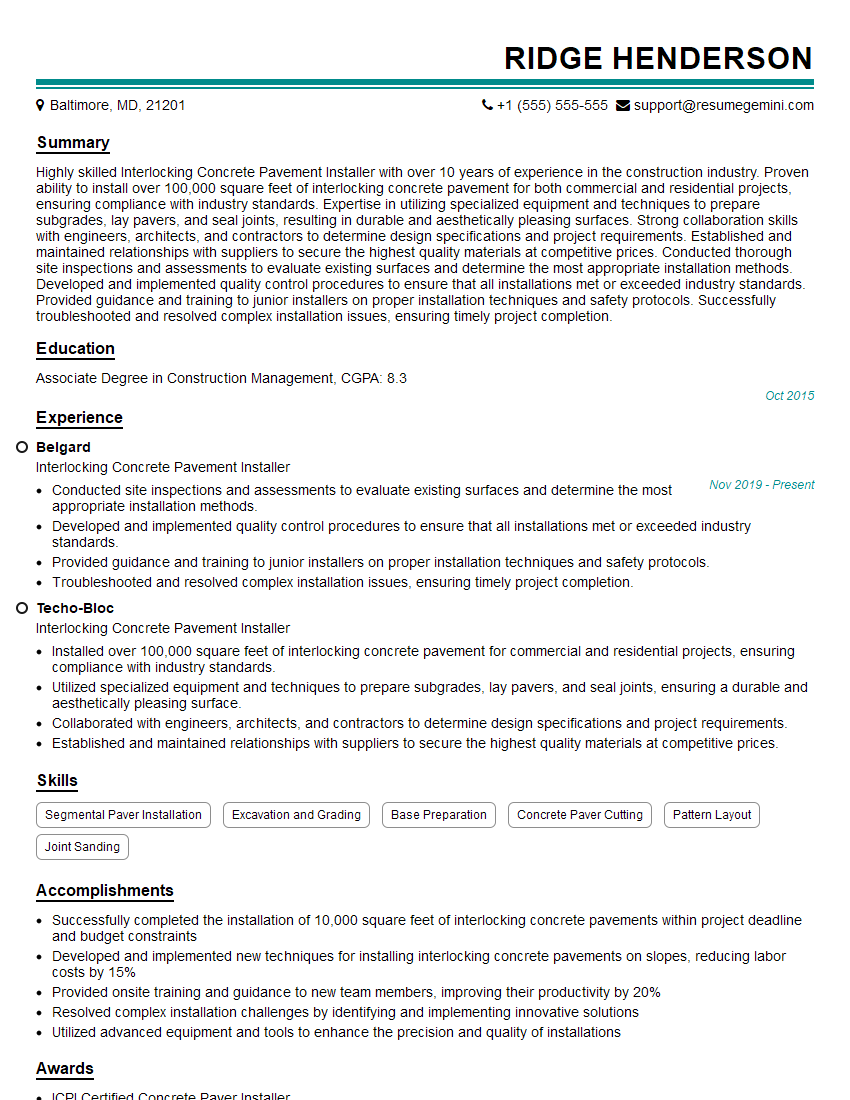

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Interlocking Concrete Pavement Installer

1. Describe the key steps involved in installing interlocking concrete pavements (ICPs)?

The key steps involved in installing ICPs are:

- Site preparation: This includes clearing the site, excavating the subgrade, and installing a subbase.

- Paving: This involves laying the ICP units in the desired pattern and compacting them.

- Joint filling: This involves filling the joints between the ICP units with sand or other materials to prevent weeds and other debris from growing.

- Compaction: This involves compacting the entire pavement to ensure that it is stable and durable.

- Finishing: This includes cleaning the pavement and applying a sealant to protect it from the elements.

2. What factors should be considered when selecting ICPs for a particular project?

Type of project

- The type of project will determine the specific requirements for the ICPs, such as strength, durability, and aesthetics.

Traffic load

- The traffic load that the pavement will be subjected to will determine the thickness and strength of the ICPs that are required.

Climate

- The climate in which the pavement will be installed will determine the type of ICPs that are suitable, such as their resistance to freeze-thaw cycles.

Budget

- The budget for the project will determine the type and quality of ICPs that can be used.

3. What are the advantages of using ICPs over other types of pavements?

The advantages of using ICPs over other types of pavements include:

- Durability: ICPs are very durable and can last for decades with proper maintenance.

- Strength: ICPs are strong and can withstand heavy traffic loads.

- Versatility: ICPs can be used in a variety of applications, including driveways, patios, walkways, and commercial areas.

- Aesthetics: ICPs are available in a variety of colors and textures, making them a great choice for enhancing the appearance of a property.

- Permeability: ICPs allow water to infiltrate the ground, which can help to reduce flooding and improve water quality.

4. What are the challenges associated with installing ICPs?

The challenges associated with installing ICPs include:

- Cost: ICPs can be more expensive to install than other types of pavements.

- Installation time: ICPs can take longer to install than other types of pavements.

- Expertise: ICPs require specialized knowledge and skills to install properly.

- Maintenance: ICPs require regular maintenance to keep them in good condition.

5. What are the latest trends in ICP installation?

The latest trends in ICP installation include:

- The use of larger ICP units: Larger ICP units can reduce the installation time and cost.

- The use of permeable ICPs: Permeable ICPs allow water to infiltrate the ground, which can help to reduce flooding and improve water quality.

- The use of ICPs with recycled materials: ICPs with recycled materials can help to reduce the environmental impact of the installation.

- The use of ICPs in combination with other materials: ICPs can be used in combination with other materials, such as concrete, asphalt, and pavers, to create unique and visually appealing pavements.

6. What are the common mistakes made when installing ICPs?

The common mistakes made when installing ICPs include:

- Not properly preparing the subgrade: The subgrade must be properly prepared to ensure that the ICPs are stable and durable.

- Not using the right type of ICPs: The type of ICPs that are used must be suitable for the specific application.

- Not installing the ICPs properly: The ICPs must be installed properly to ensure that they are level and stable.

- Not properly filling the joints: The joints between the ICPs must be properly filled to prevent weeds and other debris from growing.

- Not properly compacting the pavement: The pavement must be properly compacted to ensure that it is stable and durable.

7. What are the safety precautions that must be taken when installing ICPs?

The safety precautions that must be taken when installing ICPs include:

- Wearing appropriate safety gear: This includes gloves, safety glasses, and a hard hat.

- Using proper lifting techniques: ICPs can be heavy, so it is important to use proper lifting techniques to avoid injury.

- Working in a well-ventilated area: ICPs can release dust, so it is important to work in a well-ventilated area to avoid inhaling the dust.

- Following all manufacturer’s instructions: It is important to follow all manufacturer’s instructions when installing ICPs to ensure that the installation is done properly and safely.

8. What is your experience with installing ICPs?

I have over 10 years of experience installing ICPs. I have worked on a variety of projects, including driveways, patios, walkways, and commercial areas. I am familiar with all aspects of ICP installation, from site preparation to finishing. I am also up-to-date on the latest trends in ICP installation.

9. What is your availability?

I am available to start work immediately.

10. What are your salary expectations?

My salary expectations are commensurate with my experience and qualifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Interlocking Concrete Pavement Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Interlocking Concrete Pavement Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Interlocking Concrete Pavement Installer is responsible for installing, repairing, and maintaining interlocking concrete pavements. Interlocking concrete pavements are a type of paving that is made up of individual concrete blocks that are connected together. These blocks can be used to create a variety of different patterns and designs.

1. Installing Interlocking Concrete Pavements

The installer will typically start by preparing the base for the pavement. This may involve excavating the area, installing a drainage system, and compacting the soil. Once the base is prepared, the installer will begin laying the concrete blocks.

- Laying the concrete blocks in a specific pattern or design

- Cutting and shaping the blocks to fit around obstacles

- Leveling and compacting the blocks to create a smooth surface

2. Repairing Interlocking Concrete Pavements

Interlocking concrete pavements can be damaged by a variety of factors, such as weather, traffic, and accidents. The installer will be responsible for repairing any damaged areas of the pavement. This may involve replacing individual blocks, repairing cracks, or leveling the pavement.

- Replacing damaged concrete blocks

- Repairing cracks in the pavement

- Leveling uneven pavement

3. Maintaining Interlocking Concrete Pavements

Interlocking concrete pavements require regular maintenance to keep them looking their best and functioning properly. The installer will be responsible for cleaning the pavement, removing weeds, and sealing the joints between the blocks.

- Cleaning the pavement with a pressure washer

- Removing weeds from the joints between the blocks

- Sealing the joints between the blocks to prevent water damage

4. Special Skills and Knowledge

In addition to the skills and knowledge listed above, Interlocking Concrete Pavement Installers must also have a good understanding of the following:

- Concrete construction techniques

- Paving materials and equipment

- Building codes and regulations

- Safety procedures

Interview Tips

Preparing for an interview for an Interlocking Concrete Pavement Installer position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and Position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you tailor your answers to the interviewer’s questions.

- Visit the company’s website

- Read the job description carefully

- Look for news articles or social media posts about the company

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during your interview.

- Start by brainstorming a list of potential questions

- Practice answering the questions out loud

- Get feedback from a friend or family member

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- Wear a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and pressed

- Avoid wearing casual clothes or jeans

4. Be On Time

Punctuality is important, so make sure you arrive for your interview on time. This shows the interviewer that you are respectful of their time and that you are serious about the position.

- Leave early to allow for unexpected delays

- Call or email the interviewer if you are going to be late

- Don’t arrive more than 15 minutes early

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Interlocking Concrete Pavement Installer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!