Are you gearing up for an interview for a Interlocking Installer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Interlocking Installer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

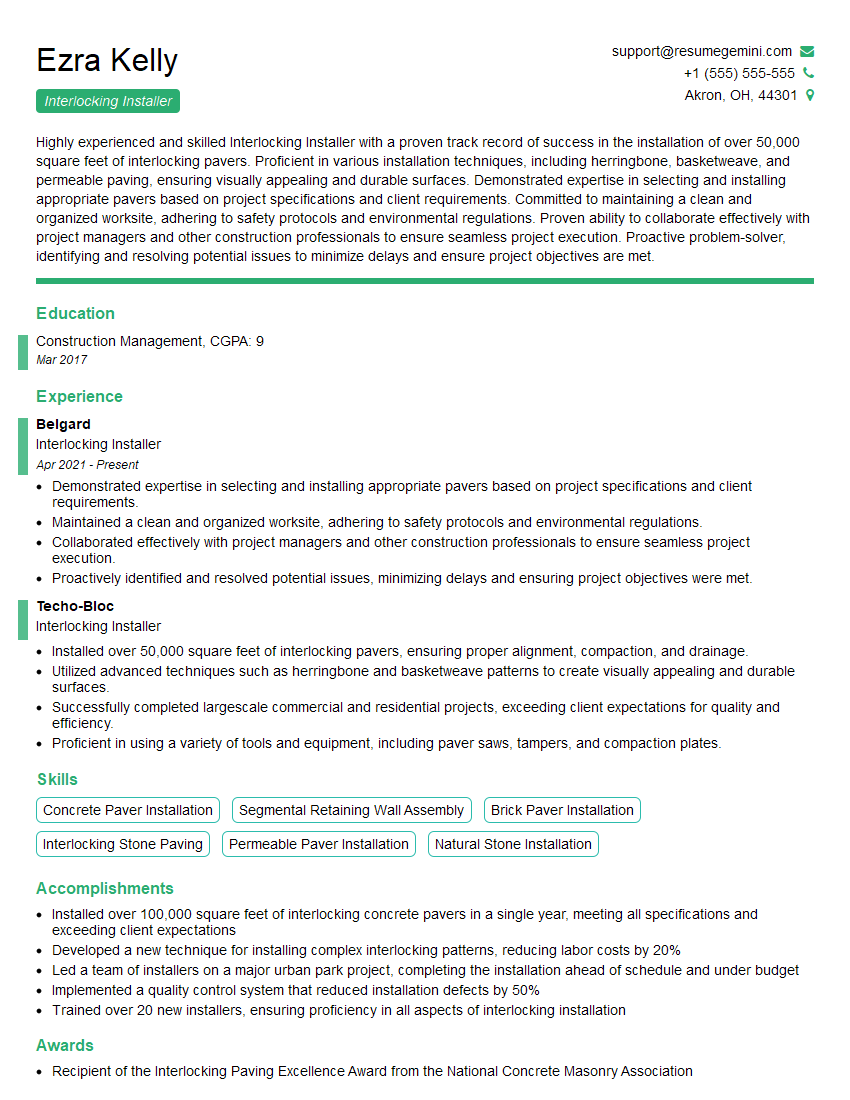

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Interlocking Installer

1. Which tools and equipment are essential for interlocking installation?

For interlocking installation, essential tools and equipment include:

- Compactor or vibrating plate

- Edger or straight edge

- Level or laser level

- Rubber mallet or hammer

- Cutting tools (e.g., saw, grinder)

- Measuring tape and chalk line

- Brooms or blowers for cleaning

- Jointing sand or polymeric sand

- Safety gear (e.g., gloves, goggles, dust mask)

2. Describe the proper sequence of steps for installing interlocking pavers.

The proper sequence of steps for installing interlocking pavers involves:

Subgrade Preparation

- Excavate and compact the subgrade to the desired depth and slope.

- Install a geotextile fabric to prevent weed growth and soil migration.

Base Layer Installation

- Spread and compact a base layer of crushed stone or gravel.

Screeding and Leveling

- Set up screed rails or use a laser level to establish the desired elevation.

- Spread and level a bedding layer of sand or fine gravel.

Paver Installation

- Install the interlocking pavers in a running bond pattern or as per the design.

- Use a rubber mallet or hammer to tap the pavers into place.

- Check for level and adjust as needed.

Jointing and Compaction

- Apply jointing sand or polymeric sand between the pavers.

- Compact the pavers using a vibrating plate or hand tampers.

3. What factors should be considered when selecting interlocking pavers for a specific project?

When selecting interlocking pavers for a specific project, key factors to consider include:

- Intended use and traffic load

- Desired appearance and aesthetics

- Climate and weather conditions

- Subgrade conditions and soil type

- Budget and cost considerations

- Availability and lead times

- Environmental impact and sustainability

- Manufacturer’s specifications and warranties

4. How do you handle slopes and curves when installing interlocking pavers?

To handle slopes and curves during interlocking paver installation:

Slopes

- Create a stable subgrade with proper drainage.

- Use a retaining wall or edge restraint to prevent paver movement.

- Install pavers in a herringbone pattern or use a slope paver system.

Curves

- Use flexible pavers or cut pavers to create curves.

- Install pavers in a radial pattern or use a curved paver system.

- Gradually adjust the angle of the pavers as you follow the curve.

5. What are the most common problems encountered during interlocking paver installation and how do you troubleshoot them?

Some common problems and troubleshooting tips for interlocking paver installation include:

Paver Movement

- Check subgrade stability and compaction.

- Install edge restraints and/or polymeric sand.

Uneven Surfaces

- Check for level during installation and adjust pavers as needed.

- Use a screed or laser level to ensure proper leveling.

Weed Growth

- Install a geotextile fabric beneath the subgrade.

- Use jointing sand that inhibits weed growth.

- Apply herbicides or weed killers as necessary.

6. How do you ensure proper drainage and prevent water buildup when installing interlocking pavers?

To ensure proper drainage and prevent water buildup during interlocking paver installation:

- Slope the pavers away from buildings and other structures.

- Create a crown or slight slope in the subgrade for water runoff.

- Provide a drainage system beneath the pavers with perforated pipes or gravel.

- Use permeable pavers or jointing materials that allow water to infiltrate.

7. What are the advantages of using interlocking pavers over other paving materials?

Interlocking pavers offer several advantages over other paving materials, including:

- Durability and longevity

- Versatility and design flexibility

- Easy installation and maintenance

- Permeability and drainage capabilities

- Environmental friendliness and sustainability

- Cost-effectiveness in the long run

8. Describe the maintenance procedures for interlocking pavers to ensure their longevity and appearance.

To maintain the longevity and appearance of interlocking pavers, regular maintenance is essential, which includes:

- Sweeping or blowing away debris and dirt.

- Power washing to remove stains or buildup.

- Resealing the pavers as needed to protect them from wear and weather.

- Inspecting and repairing any damaged or loose pavers.

- Applying jointing sand or polymeric sand to fill gaps and prevent weeds.

- Trimming grass or vegetation around the edges of the pavers.

9. How do you estimate the quantity of interlocking pavers needed for a given project?

To estimate the quantity of interlocking pavers needed for a project:

- Measure the area to be paved in square feet.

- Determine the size of the pavers to be used.

- Calculate the number of pavers per square foot by dividing 144 (square inches per square foot) by the paver’s surface area in square inches.

- Multiply the number of pavers per square foot by the total area to be paved.

- Add 10-15% for waste and cutting.

10. What is your preferred method of cutting interlocking pavers?

My preferred method of cutting interlocking pavers depends on the thickness and type of paver, but typically I use one of the following:

- Wet saw: For precise, clean cuts on thick or hard pavers.

- Angle grinder: For rough or curved cuts on medium-thickness pavers.

- Paver splitter: For quick, straight cuts on thin or brittle pavers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Interlocking Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Interlocking Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Interlocking Installer performs a critical role in the construction and maintenance of interlocking paving systems, ensuring the durability and aesthetic appeal of these surfaces. The key responsibilities of an Interlocking Installer include:

1. Installation and Repair of Interlocking Pavers

Interlocking Installers are responsible for the expert installation of interlocking pavers in various applications, including driveways, patios, walkways, and commercial areas. They meticulously prepare the base, lay the pavers in the desired pattern, and secure them to create a level and stable surface.

2. Cutting and Fitting Pavers

To achieve a seamless and aesthetically pleasing finished product, Interlocking Installers expertly cut and fit pavers to accommodate curves, edges, and obstacles. They utilize specialized tools and techniques to ensure precision and minimize waste.

3. Base Preparation and Compaction

The foundation of any interlocking paving system is crucial, and Interlocking Installers play a vital role in preparing and compacting the base. They excavate the area, grade it to the appropriate slope, and compact it to provide a solid and well-drained surface for the pavers.

4. Joint Sanding and Compaction

Once the pavers are installed, Interlocking Installers fill the joints between them with specialized joint sand. This process, known as joint sand compaction, helps to lock the pavers in place and prevents weed growth, ensuring the longevity and stability of the surface.

5. Quality Control and Maintenance

Interlocking Installers are responsible for maintaining the quality of their work and ensuring that the installed surfaces meet industry standards. They conduct regular inspections, identify any potential issues, and perform timely repairs to maintain the integrity and appearance of the interlocking paving system.

Interview Tips

Preparing thoroughly for an Interlocking Installer interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to thoroughly research the company you’re applying to, as well as the specific Interlocking Installer position. This will demonstrate your interest and enthusiasm for the role and help you tailor your answers to the interviewer’s questions.

2. Highlight Your Skills and Experience

Emphasize your proficiency in the key responsibilities of an Interlocking Installer, as outlined in the job description. Showcase your experience in preparing and compacting base, installing and repairing pavers, and performing joint sand compaction. Provide specific examples that illustrate your abilities.

3. Prepare for Technical Questions

Interviewers may ask technical questions to assess your understanding of interlocking paving systems. Be prepared to discuss the different types of pavers, installation techniques, joint sand compaction methods, and common challenges you’ve encountered in the field.

4. Demonstrate Your Physical Ability

Interlocking Installer work can be physically demanding. During the interview, be prepared to discuss your physical capabilities and how you handle heavy lifting, kneeling, and working outdoors in various weather conditions.

5. Ask Informed Questions

Asking insightful questions at the end of the interview shows your engagement and interest in the position. Prepare questions that demonstrate your knowledge of the industry, such as the company’s environmental practices or the latest trends in interlocking paving technology.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Interlocking Installer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!