Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Intermediate Frame Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Intermediate Frame Tender so you can tailor your answers to impress potential employers.

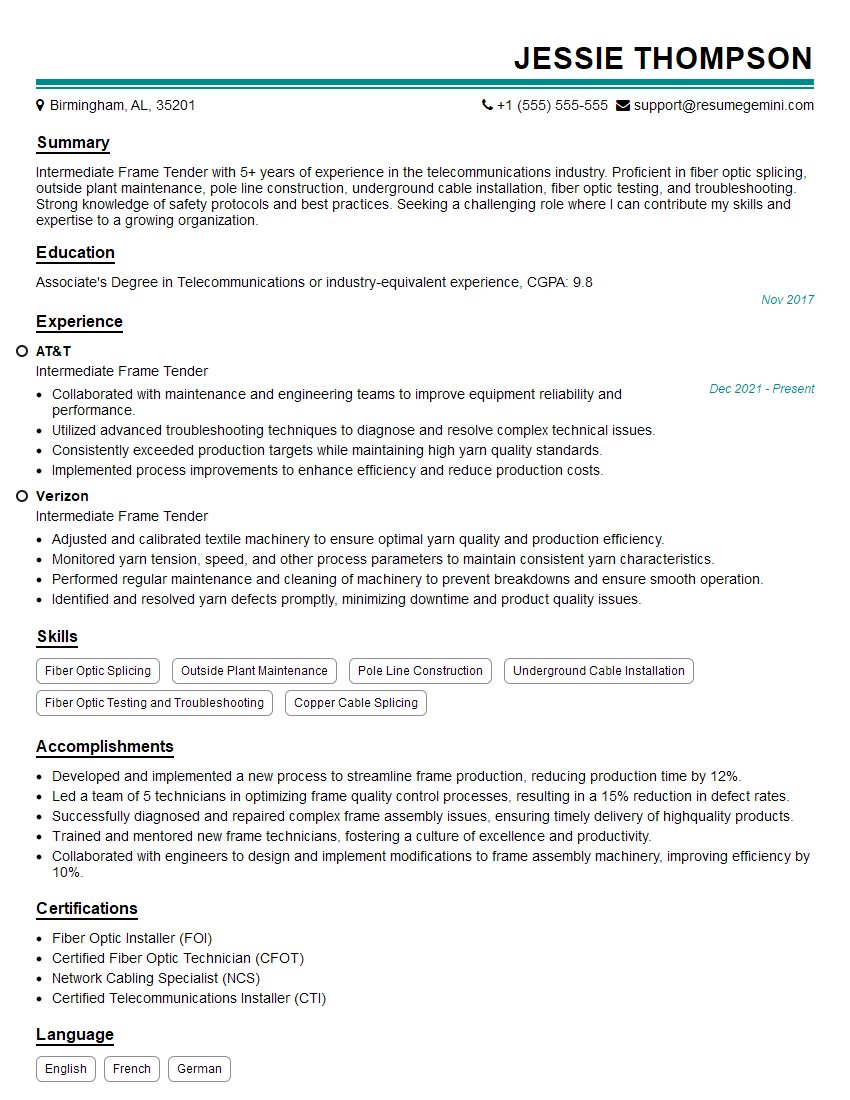

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Intermediate Frame Tender

1. Describe the key responsibilities of an Intermediate Frame Tender.

- Operate and monitor frame tender machines to produce high-quality frames.

- Set up and adjust the machine according to work orders and specifications.

- Inspect frames in progress and finished frames to ensure they meet quality standards.

- Troubleshoot and resolve machine issues and production problems.

- Maintain a clean and organized work area, following safety protocols.

2. Explain how you ensure the quality of frames produced on the frame tender machine.

- Regularly check and calibrate the machine to maintain precision.

- Inspect frames visually for defects or inconsistencies in size and shape.

- Use measuring tools to ensure frames meet dimensional specifications.

- Monitor production data and identify anomalies or trends that may indicate quality issues.

- Work closely with quality control team to resolve any quality concerns promptly.

3. Describe the process of setting up the frame tender machine based on a work order.

- Review the work order for material specifications, frame dimensions, and production quantity.

- Select and load the appropriate material into the machine.

- Adjust the machine settings and parameters according to the work order.

- Confirm that the machine is operating correctly by running a test piece.

- Document the setup process and any deviations from the work order for future reference.

4. How do you handle machine breakdowns and production problems?

- Immediately identify the issue and its potential cause.

- Consult with colleagues or maintenance personnel if the issue is complex.

- Follow established troubleshooting procedures to identify and resolve the problem.

- Adjust machine settings or make minor repairs to address the issue.

- Report any major issues to the supervisor and collaborate on solutions.

5. Describe the safety protocols you follow when operating the frame tender machine.

- Wear appropriate personal protective equipment, such as gloves and safety glasses.

- Ensure the machine is properly grounded and all guards are in place.

- Avoid loose clothing or jewelry that could get caught in the machine.

- Never reach into the machine while it is running.

- Report any unsafe conditions or potential hazards to the supervisor immediately.

6. How do you maintain and clean the frame tender machine to ensure optimal performance?

- Regularly clean the machine using appropriate cleaning agents.

- Lubricate moving parts according to the manufacturer’s recommendations.

- Inspect and replace worn or damaged components as needed.

- Keep the work area clean and free of debris to prevent contamination.

- Monitor machine performance and document any maintenance or repairs performed.

7. Explain how you utilize production data to identify areas for improvement in the frame tender operation.

- Track key metrics such as production output, cycle time, and defect rates.

- Identify trends, patterns, or anomalies in the data.

- Analyze the data to determine potential causes for inefficiencies or quality issues.

- Develop and implement corrective actions to address identified areas for improvement.

- Monitor results and make further adjustments as needed to optimize the frame tender operation.

8. How do you collaborate with other team members to ensure smooth production flow?

- Communicate regularly with supervisors, operators, and quality control personnel.

- Share information about machine status, production progress, and any potential issues.

- Assist colleagues with troubleshooting and problem-solving.

- Maintain a positive and cooperative work environment.

- Participate in team meetings and discussions related to production improvement.

9. Describe your experience in using quality control tools and techniques to monitor frame production.

- Use measuring instruments such as calipers, micrometers, and gauges to verify frame dimensions.

- Conduct visual inspections to identify surface defects or inconsistencies.

- Create and maintain inspection reports and documentation.

- Participate in quality control meetings to discuss findings and implement improvements.

- Stay updated on industry best practices and quality control standards.

10. How do you stay updated on new developments and technological advancements in the frame tender industry?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Network with other professionals in the field.

- Explore online resources and webinars.

- Seek opportunities for professional development and training.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Intermediate Frame Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Intermediate Frame Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Intermediate Frame Tenders are responsible for ensuring the smooth functioning of textile manufacturing machinery. Their primary duties include:

1. Production Monitoring and Adjustment

Monitoring the operation of weaving frames and making necessary adjustments to maintain optimal production quality and efficiency

- Adjusting warp and weft tension

- Monitoring yarn breakage and taking corrective actions

2. Machine Maintenance and Troubleshooting

Performing routine maintenance and repairs on weaving machines to prevent breakdowns and ensure smooth operations

- Cleaning and lubricating machinery components

- Identifying and resolving minor machine malfunctions

3. Quality Inspection and Reporting

Inspecting the quality of woven fabric and reporting any defects or inconsistencies to ensure compliance with specifications

- Identifying and marking defective fabric

- Maintaining records of fabric quality and reporting to supervisors

4. Material Handling and Logistics

Loading and unloading warp beams and yarn onto weaving machines, ensuring proper inventory management and material flow

- Operating forklifts or other material handling equipment

- Maintaining an organized and efficient work area

Interview Tips

Interview preparation is crucial to ace an interview. Here are some tips for candidates applying for an Intermediate Frame Tender position:

1. Research the Company and Position

Thoroughly research the company, including its products, services, industry standing, and company culture. This will provide you with a comprehensive understanding of the organization and demonstrate your interest in the role.

- Visit the company’s website and social media pages

- Review industry publications and news articles

2. Practice Common Interview Questions

Prepare for common interview questions related to your experience, skills, and motivation. By practicing your answers in advance, you can deliver them confidently and clearly.

3. Highlight Relevant Skills and Experience

Showcase your skills and experience that are applicable to the role. Emphasize your proficiency in operating weaving machines, performing maintenance, and ensuring fabric quality. Quantify your accomplishments with specific examples whenever possible.

- Describe your previous responsibilities and how they relate to the job

- Provide examples of successful projects or initiatives you have been involved in

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position. Prepare a few questions related to the company, the role, or the industry to show that you are invested in the opportunity.

- Ask about the company’s growth plans or future projects

- Inquire about opportunities for professional development or advancement

Next Step:

Now that you’re armed with the knowledge of Intermediate Frame Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Intermediate Frame Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini