Feeling lost in a sea of interview questions? Landed that dream interview for Internal Grinder Set-Up Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Internal Grinder Set-Up Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

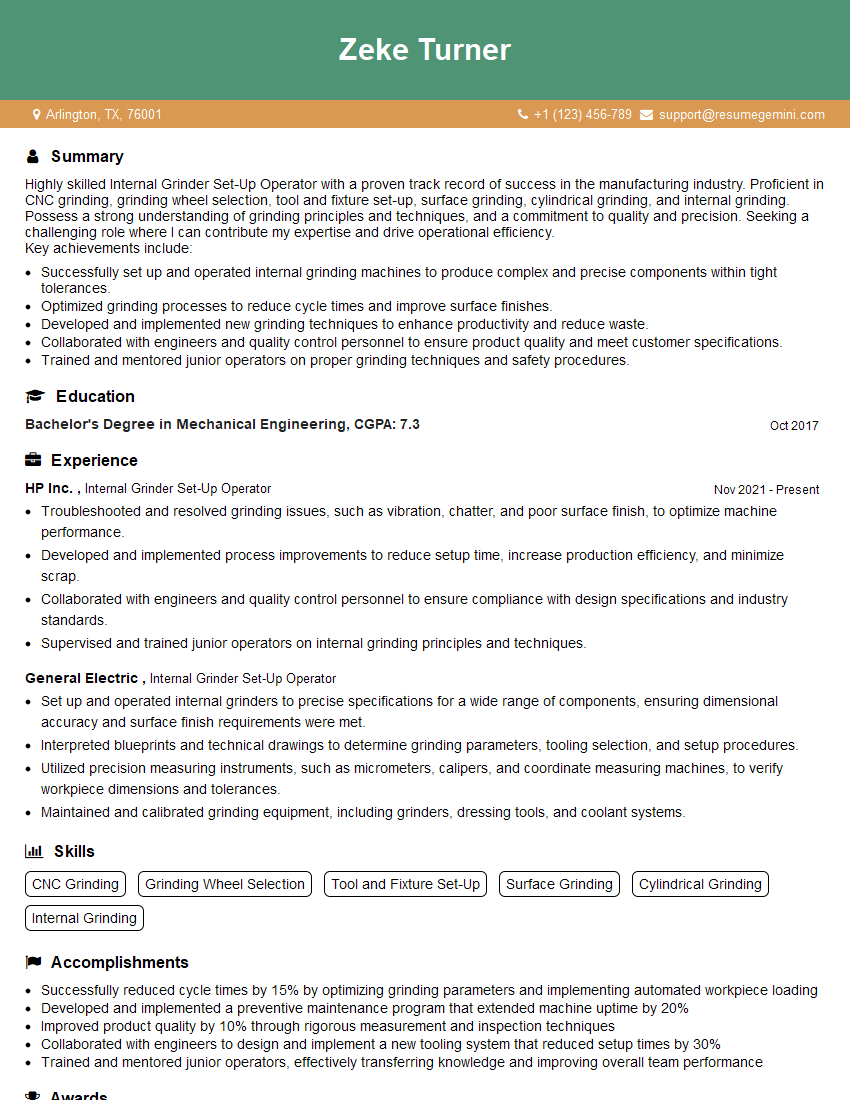

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Internal Grinder Set-Up Operator

1. What are the different types of internal grinding machines?

There are three main types of internal grinding machines: centerless, cylindrical, and surface.

- Centerless internal grinding machines are used to grind the inside of cylindrical parts without the use of centers. This type of machine is typically used for high-volume production of small parts.

- Cylindrical internal grinding machines are used to grind the inside of cylindrical parts between centers. This type of machine is typically used for grinding larger parts that require higher precision.

- Surface internal grinding machines are used to grind the inside of flat surfaces. This type of machine is typically used for grinding surfaces that require a high degree of flatness and surface finish.

2. What are the key factors to consider when selecting an internal grinding wheel?

Grit:

- The grit of the grinding wheel determines the size of the abrasive particles.

- A finer grit wheel will produce a smoother surface finish, while a coarser grit wheel will remove material more quickly.

Bond:

- The bond of the grinding wheel determines how the abrasive particles are held together.

- A harder bond will produce a more durable wheel, while a softer bond will allow the wheel to conform to the shape of the workpiece.

Structure:

- The structure of the grinding wheel determines the spacing between the abrasive particles.

- A more open structure will allow for better chip clearance, while a denser structure will produce a finer surface finish.

3. How do you set up an internal grinding machine?

- Install the grinding wheel and dress it to the desired shape.

- Mount the workpiece on the machine table.

- Set the machine parameters, including the spindle speed, feed rate, and depth of cut.

- Start the grinding cycle and monitor the process.

4. How do you measure the inside diameter of a bore?

- Use a bore gauge to measure the diameter of the bore.

- A bore gauge is a precision instrument that consists of a set of telescoping rods with a micrometer head at the end.

- The rods are inserted into the bore and the micrometer head is used to measure the diameter.

5. What are the common problems that can occur during internal grinding?

- Chatter: Chatter is a vibration that can occur during internal grinding. This can be caused by a number of factors, such as an unbalanced grinding wheel, a loose workpiece, or a worn-out spindle.

- Burnishing: Burnishing is a condition in which the grinding wheel rubs against the workpiece instead of cutting it. This can cause the workpiece to become glazed and can lead to poor surface finish.

- Loading: Loading is a condition in which the grinding wheel becomes clogged with metal chips. This can cause the wheel to lose its cutting ability and can lead to poor surface finish.

6. How do you troubleshoot a chattering grinding machine?

- Check the grinding wheel for balance.

- Tighten the workpiece.

- Check the spindle for wear.

- Reduce the feed rate.

7. How do you select the correct grinding parameters for a given job?

- Consider the material of the workpiece.

- Consider the desired surface finish.

- Consider the size and shape of the workpiece.

- Refer to the manufacturer’s recommendations for the grinding machine.

8. What are the safety precautions that must be taken when operating an internal grinding machine?

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Never operate the machine with the door open.

- Use a grinding wheel guard to protect yourself from flying chips.

- Follow all manufacturer’s instructions for safe operation.

9. What is the difference between a plunge grind and a traverse grind?

- Plunge grinding is a process in which the grinding wheel is moved directly into the workpiece.

- Traverse grinding is a process in which the grinding wheel is moved across the workpiece.

- Plunge grinding is typically used for grinding deep bores, while traverse grinding is typically used for grinding shallow bores.

10. What are the advantages of using CBN grinding wheels?

- CBN grinding wheels are harder than traditional grinding wheels, which makes them more durable.

- CBN grinding wheels produce a sharper cutting edge, which results in a better surface finish.

- CBN grinding wheels are less likely to load up, which means that they can be used for longer periods of time.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Internal Grinder Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Internal Grinder Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Internal Grinder Set-Up Operators play a crucial role in manufacturing by setting up, programming, and operating internal grinding machines to produce precision parts.

1. Set-Up and Calibration

Establish proper set-up of internal grinding machines, including spindle speed, feed rate, and coolant flow parameters.

- Mount workpieces, grinding wheels, and other attachments.

- Calibrate and test machines to ensure accuracy and performance.

2. Programming and Operating

Program machines using CNC (Computer Numerical Control) systems to execute grinding operations.

- Monitor grinding processes, adjust parameters as needed, and ensure quality control.

- Troubleshoot machine malfunctions, identify causes, and resolve issues.

3. Quality Control

Measure and inspect finished products to meet specifications and tolerances.

- Maintain accurate records of measurements, inspections, and machine settings.

- Identify and implement corrective actions to improve quality and efficiency.

4. Maintenance and Repair

Perform routine maintenance and repairs on grinding machines to ensure optimal operation.

- Lubricate, clean, and adjust machine components as required.

- Coordinate with maintenance personnel for major repairs or overhauls.

Interview Tips

Preparing for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for an Internal Grinder Set-Up Operator position:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products/services, and culture. Research the specific role and its responsibilities to demonstrate your knowledge and interest.

- Visit the company website and social media pages.

- Review job descriptions and any available company literature.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills, such as CNC programming, grinding machine operation, and quality control. Quantify your accomplishments whenever possible to showcase the impact of your work.

- Describe your experience with specific internal grinding machines and processes.

- Provide examples of how you have met or exceeded quality standards.

3. Demonstrate Problem-Solving Abilities

Interviewers want to know that you can handle challenges effectively. Share situations where you identified and resolved machine malfunctions or quality issues.

- Explain your approach to troubleshooting and problem-solving.

- Discuss how you prioritize tasks and manage deadlines.

4. Prepare Questions

Asking thoughtful questions shows that you are engaged and interested in the position. Prepare questions about the company’s operations, quality standards, and opportunities for professional development.

- Inquire about the latest technologies or industry trends.

- Ask about the company’s commitment to employee training.

5. Practice and Confidence

Rehearse answering common interview questions to build confidence and fluency. Dress professionally and arrive on time for your interview. Maintain a positive attitude and show enthusiasm for the role.

- Consider using a mock interview tool or practicing with a friend or family member.

- Remember to smile, make eye contact, and speak clearly.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Internal Grinder Set-Up Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.