Feeling lost in a sea of interview questions? Landed that dream interview for Inventory Control/Shipping-Receiving but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Inventory Control/Shipping-Receiving interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

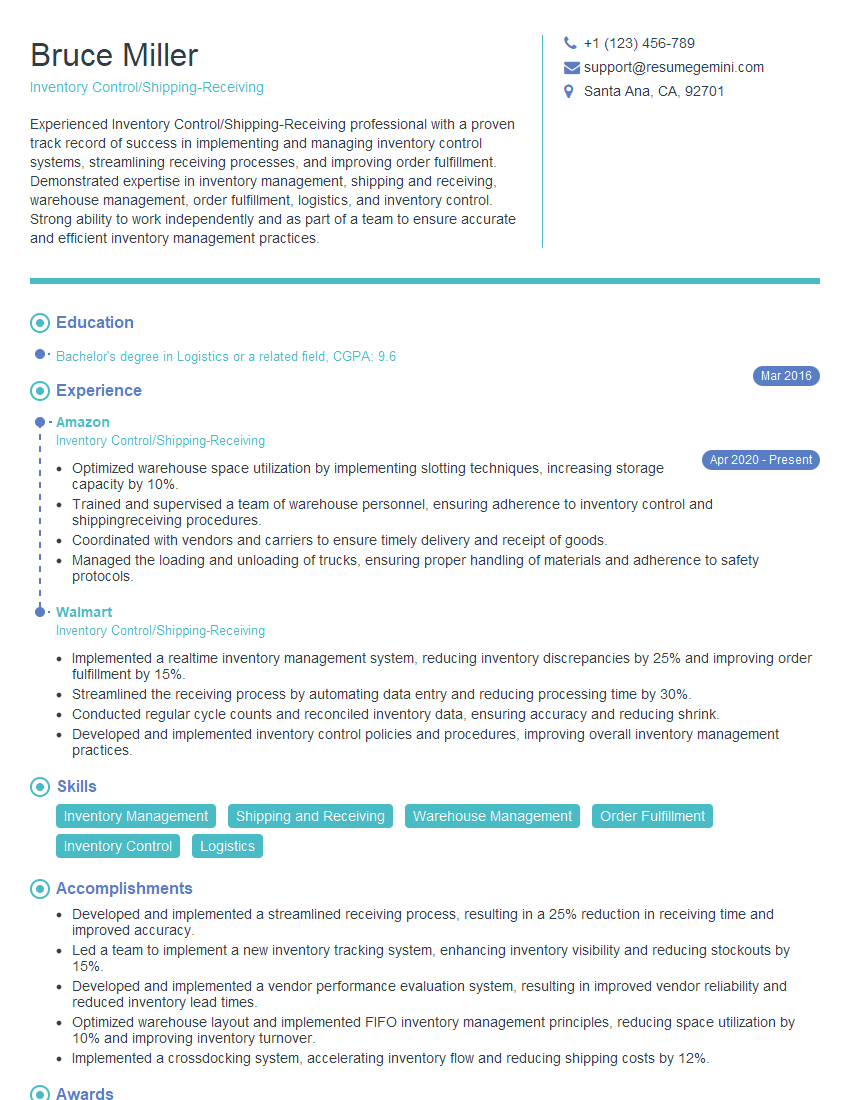

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Inventory Control/Shipping-Receiving

1. Describe the key steps involved in the inventory control process?

The inventory control process involves several key steps:

- Demand forecasting: Determining future demand for inventory based on historical data, market trends, and other factors.

- Inventory planning: Establishing inventory levels and re-order points to meet demand while minimizing costs.

- Inventory receiving: Inspecting, counting, and storing incoming goods to ensure accuracy and prevent discrepancies.

- Inventory storage: Managing inventory levels, optimizing storage space, and implementing proper inventory handling techniques.

- Inventory issuing: Processing orders, picking and issuing goods to meet customer or production needs.

- Inventory tracking: Maintaining up-to-date records of inventory levels, locations, and transactions to ensure accuracy and control.

- Inventory replenishment: Monitoring inventory levels and triggering re-orders to maintain desired stock levels.

- Cycle counting: Conducting periodic physical counts to verify inventory accuracy and identify discrepancies.

- Inventory reporting: Generating reports on inventory levels, turnover rates, and other metrics to support decision-making.

2. What are the different types of inventory control systems and their advantages and disadvantages?

Periodic inventory system

- Advantages: Simple and less expensive to implement, minimizes record-keeping.

- Disadvantages: Only provides a snapshot of inventory levels at specific time points, may result in stockouts or overstocking.

Perpetual inventory system

- Advantages: Provides real-time inventory information, allows for better inventory management and control.

- Disadvantages: More complex and expensive to implement, requires continuous record-keeping.

Hybrid inventory system

- Advantages: Combines the advantages of both perpetual and periodic systems, providing a balance between accuracy and cost.

- Disadvantages: Can be more complex to implement and manage than the other two systems.

3. Describe the different methods used for inventory valuation?

Inventory valuation methods include:

- First-in, first-out (FIFO): Assumes that the oldest inventory is sold first, resulting in the cost of goods sold being based on the cost of the oldest inventory.

- Last-in, first-out (LIFO): Assumes that the most recently purchased inventory is sold first, resulting in the cost of goods sold being based on the cost of the most recent inventory.

- Average cost: Calculates the average cost of goods sold based on the weighted average of all inventory purchases.

4. What are the key performance indicators (KPIs) used to measure the effectiveness of inventory control?

- Inventory turnover rate: Measures how efficiently inventory is being used and sold.

- Days sales in inventory (DSI): Indicates the average number of days it takes to sell inventory.

- Inventory accuracy: Measures the accuracy of inventory records compared to physical counts.

- Stockout rate: Indicates the percentage of customer orders that cannot be fulfilled due to insufficient inventory.

- Inventory holding costs: Measures the cost of holding inventory, including storage, insurance, and handling.

5. What are the common causes of inventory discrepancies and how can they be prevented?

- Receiving errors: Mistakes made during the receiving process, such as incorrect counts or misidentified items.

- Shipping errors: Errors made during the shipping process, such as incorrect quantities or damaged goods.

- Theft or pilferage: Unauthorized removal of inventory without proper documentation.

- Damage or spoilage: Inventory that becomes damaged or spoiled during storage or handling.

To prevent discrepancies, it is important to implement strong receiving and shipping procedures, conduct regular inventory audits, and invest in security measures.

6. Describe the different techniques used for inventory optimization?

- ABC analysis: Classifying inventory items based on their value and criticality.

- Just-in-time (JIT) inventory: Aiming to minimize inventory levels by receiving goods just as they are needed for production or sale.

- Safety stock: Maintaining a buffer of extra inventory to prevent stockouts during periods of high demand or supply chain disruptions.

- Vendor-managed inventory (VMI): Allowing suppliers to manage inventory levels on behalf of the customer.

7. How do you manage inventory levels in response to fluctuations in demand?

To manage inventory levels effectively in response to demand fluctuations, it is important to:

- Monitor demand patterns and forecast future demand.

- Adjust inventory levels based on demand forecasts and lead times.

- Implement safety stock strategies to buffer against unexpected surges in demand or supply chain disruptions.

8. What are the key elements of an effective shipping and receiving process?

- Clear communication: Establishing clear communication channels between shipping, receiving, and other departments.

- Efficient processing: Streamlining the receiving process to minimize delays and errors.

- Accurate documentation: Maintaining accurate records of all shipments and receipts.

- Inventory control: Integrating shipping and receiving processes with inventory control systems to ensure accurate inventory counts.

- Collaboration: Fostering collaboration between shipping and receiving departments to optimize the overall process.

9. How do you ensure the proper handling and storage of inventory?

Ensuring proper handling and storage of inventory is crucial to maintain its quality and prevent damage:

- Establish clear guidelines for inventory handling, including proper lifting techniques and storage practices.

- Train staff on proper inventory handling procedures.

- Implement storage systems that protect inventory from damage, such as climate-controlled warehouses or specialized packaging.

- Regularly inspect inventory to identify any damage or deterioration.

10. How do you manage inventory in a multi-location environment?

Managing inventory in a multi-location environment requires effective coordination and communication:

- Establish clear inventory policies and procedures across all locations.

- Implement a centralized inventory management system to track inventory levels and transactions in real-time.

- Foster communication and collaboration between different locations to ensure accurate inventory information.

- Consider utilizing technology such as RFID or barcoding to automate inventory tracking and improve accuracy.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Inventory Control/Shipping-Receiving.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Inventory Control/Shipping-Receiving‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Inventory Control/Shipping-Receiving personnel are responsible for the efficient and accurate management of inventory, as well as the receiving and shipping of goods. They play a crucial role in ensuring that the organization has the right products, in the right quantities, at the right time.

1. Inventory Control

Maintain accurate inventory records and ensure that inventory levels are optimized

- Perform cycle counts and physical inventories to verify the accuracy of inventory records

- Identify and resolve inventory discrepancies

- Establish and maintain reorder points to ensure that inventory levels do not fall below minimum requirements

2. Shipping

Prepare and ship orders according to customer specifications

- Verify shipping information and ensure that orders are complete and accurate

- Select and pack appropriate shipping materials

- Schedule and coordinate shipments with carriers

- Track shipments and provide updates to customers

3. Receiving

Receive and inspect incoming goods and ensure that they meet quality standards

- Verify receiving information and ensure that goods are undamaged

- Inspect goods for quality and ensure that they meet specifications

- Process and record incoming goods into inventory

- Resolve any discrepancies or issues with suppliers

4. Other Responsibilities

Perform other duties as assigned, such as:

- Maintain and organize the warehouse or storage area

- Train and supervise other warehouse or shipping and receiving personnel

- Assist with inventory management and forecasting

Interview Tips

Preparing for an interview for an Inventory Control/Shipping-Receiving position requires a combination of research, practice, and confidence. Here are some tips to help you ace the interview:

1. Research the company and the position

Take the time to learn about the company’s products, services, and industry. Research the specific position you are applying for and identify the key responsibilities and qualifications.

- Visit the company’s website and read about their mission, values, and culture.

- Look for news articles or industry reports that mention the company.

- Review the job description carefully and identify the specific skills and experience the employer is seeking.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” Prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your skills and experience.

- Practice your answers out loud so that you can become comfortable with the delivery.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your relevant experience and skills. Be prepared to discuss your experience in inventory control, shipping, and receiving. Highlight your strengths and accomplishments, and be prepared to provide examples of your work.

- Quantify your accomplishments whenever possible. For example, instead of saying “I managed inventory,” you could say “I managed inventory for a warehouse with over 10,000 SKUs, resulting in a 99% inventory accuracy rate.”

- Be prepared to discuss your skills in detail. For example, if you are proficient in a particular software program, be prepared to explain how you use it and how it has benefited your previous employers.

4. Ask questions

Asking questions shows that you are interested in the position and the company. Prepare a few thoughtful questions to ask the interviewer, such as “What are the biggest challenges facing the inventory control/shipping-receiving department?” or “What are the opportunities for career advancement within the company?”

- Avoid asking questions that are easily answered by reading the job description or the company’s website.

- Ask questions that are specific to the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Inventory Control/Shipping-Receiving interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!