Are you gearing up for an interview for a Irish Moss Bleacher position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Irish Moss Bleacher and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

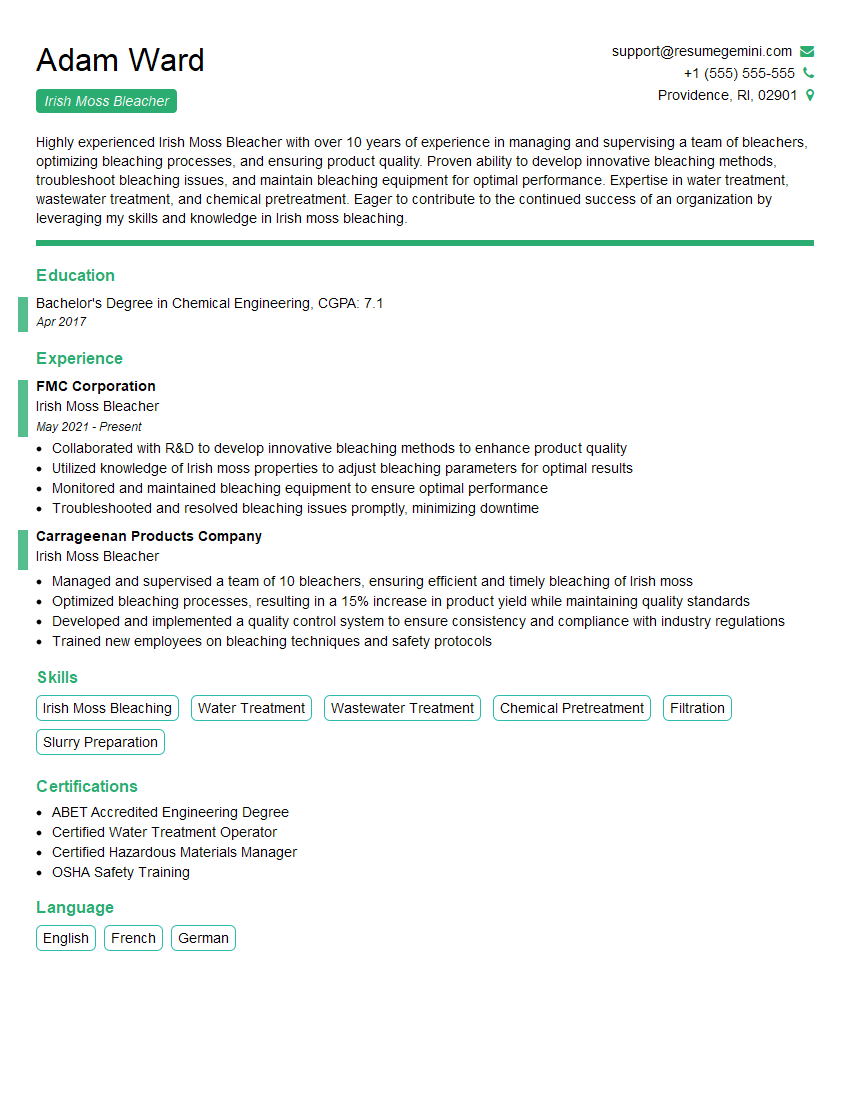

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Irish Moss Bleacher

1. Explain the role of citric acid in the Irish moss bleaching process?

Citric acid plays a crucial role in the Irish moss bleaching process as it:

- Lowers pH: Citric acid is a natural acid that helps lower the pH of the bleaching solution. A lower pH environment enhances the effectiveness of bleaching agents.

- Chelation of metal ions: Citric acid forms complexes with metal ions, such as iron, which can catalyze the decomposition of bleaching agents. By chelating these ions, citric acid prevents them from interfering with the bleaching process.

- Buffers the solution: Citric acid acts as a buffer to maintain a stable pH throughout the bleaching process. This is important as pH fluctuations can affect the activity of bleaching agents.

2. Describe the physical and chemical changes that occur in Irish moss during the bleaching process?

Physical changes:

- Color change: The natural reddish-brown color of Irish moss fades to a pale cream or white after bleaching.

- Texture change: Bleached Irish moss becomes softer and more pliable.

- Volume increase: The moss swells and increases in volume due to the absorption of water and the removal of impurities.

Chemical changes:

- Removal of pigments: Bleaching agents oxidize and break down the pigments responsible for the natural color of Irish moss.

- Degradation of polysaccharides: Bleaching can cause some degradation of the polysaccharides present in Irish moss, but this is generally minimized by careful control of the process.

- Formation of bleached polysaccharides: The bleaching process converts the colored polysaccharides into bleached polysaccharides, which are colorless and have improved functional properties.

3. What are the factors that influence the quality of bleached Irish moss?

The quality of bleached Irish moss is influenced by several factors:

- Raw material: The quality of the raw Irish moss used for bleaching is crucial. Factors such as species, harvest time, and storage conditions can affect the bleaching outcome.

- Bleaching conditions: The bleaching process parameters, including bleach concentration, temperature, and duration, need to be carefully controlled to achieve optimal bleaching results.

- Equipment: The type and condition of the equipment used for bleaching, such as the bleaching tank and agitator, can impact the efficiency and quality of the process.

- Post-bleaching treatment: Proper post-bleaching treatments, such as rinsing, washing, and drying, are essential to remove residual bleach and impurities while preserving the functional properties of the bleached moss.

4. What are the applications of bleached Irish moss in various industries?

- Food industry: Bleached Irish moss is used as a gelling, thickening, and stabilizing agent in food products such as jams, jellies, and ice cream.

- Beverage industry: It is employed as a stabilizer and clarifier in beverages like beer, wine, and fruit juices.

- Pharmaceutical industry: Bleached Irish moss finds use as an emulsifier, stabilizer, and suspending agent in pharmaceutical formulations.

- Cosmetics industry: It is utilized as a thickener, moisturizer, and emulsifier in cosmetic products such as lotions, creams, and hair care products.

- Industrial applications: Bleached Irish moss has applications in textile printing, paper making, and adhesives.

5. How can the sustainability of the Irish moss bleaching process be improved?

- Responsible harvesting: Promoting sustainable harvesting practices to ensure the long-term availability of Irish moss resources.

- Efficient water usage: Optimizing the water consumption during the bleaching process by adopting water-saving technologies.

- Waste reduction: Minimizing waste generation by recycling or repurposing byproducts from the bleaching process.

- Energy efficiency: Utilizing energy-efficient equipment and optimizing process conditions to reduce energy consumption.

- Regulatory compliance: Adhering to environmental regulations and standards to ensure responsible waste disposal and minimize pollution.

6. What are the challenges associated with the bleaching of Irish moss?

- Color consistency: Achieving uniform and consistent color in the bleached moss can be challenging due to variations in raw material quality and bleaching conditions.

- Control of degradation: Excessive bleaching can lead to degradation of the polysaccharides, which can affect the functional properties of the bleached moss.

- Process optimization: Finding the optimal balance between bleaching efficiency and preservation of the desired properties of the bleached moss can be difficult.

- Environmental concerns: The use of bleach chemicals in the bleaching process requires careful handling and disposal to minimize environmental impact.

7. What are the emerging trends in the Irish moss bleaching industry?

- Alternative bleaching methods: Exploring environmentally friendly bleaching methods using enzymes or other non-chemical approaches.

- Precision bleaching: Developing techniques to precisely control the degree of bleaching and minimize over-bleaching.

- Bleached moss derivatives: Investigating the production of value-added derivatives from bleached Irish moss, such as polysaccharide fractions and functional ingredients.

- Data analytics and automation: Utilizing data analytics and automation to optimize the bleaching process and improve quality control.

8. How do you stay updated with the latest advancements in Irish moss bleaching technology?

- Scientific literature: Reading research papers, journals, and industry publications.

- Conferences and workshops: Attending industry events and scientific conferences.

- Networking: Connecting with experts, researchers, and professionals in the field.

- Online resources: Utilizing online platforms, databases, and technical articles.

- Collaboration: Engaging in collaborative projects and partnerships to share knowledge and develop innovative solutions.

9. What is your understanding of the role of automation in the Irish moss bleaching process?

- Process monitoring and control: Automation can be used to monitor and control various process parameters such as temperature, pH, and bleach concentration.

- Material handling: Automated systems can streamline material handling operations, including the feeding of raw moss and the removal of bleached moss.

- Quality control: Automation can facilitate real-time quality control by monitoring the color and other properties of the bleached moss.

- Optimization: Automated systems can optimize the bleaching process by adjusting parameters based on real-time data and historical trends.

10. Describe your experience in troubleshooting Irish moss bleaching issues

In my previous role, I encountered a situation where the bleached moss was exhibiting uneven color. I conducted a thorough investigation and identified that the issue was related to inconsistent mixing of the bleaching solution. I worked with the production team to implement a more efficient mixing system, which resolved the problem and resulted in improved color uniformity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Irish Moss Bleacher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Irish Moss Bleacher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Irish Moss Bleacher is responsible for bleaching and preparing Irish moss for use in the food and beverage industry. Key responsibilities include:

1. Bleaching and Preparation Process

Operate bleaching equipment to bleach and prepare Irish moss according to established procedures.

- Monitor and adjust chemical concentrations, temperature, and bleaching time to ensure proper bleaching.

- Rinse and wash bleached moss to remove residual chemicals and impurities.

2. Quality Control

Inspect bleached moss for color, texture, and quality.

- Perform sensory and visual evaluations to ensure compliance with specifications.

- Conduct laboratory tests to assess bleaching effectiveness and product quality.

3. Production and Inventory Management

Maintain production schedules and ensure timely delivery of bleached moss.

- Monitor inventory levels and coordinate with procurement to maintain adequate supplies.

- Maintain accurate records of production, inventory, and quality control data.

4. Equipment Maintenance and Sanitation

Maintain and clean bleaching equipment to ensure optimal performance and hygiene.

- Calibrate and adjust equipment according to manufacturer’s specifications.

- Implement and adhere to sanitation protocols to prevent contamination.

Interview Tips

To ace an interview for an Irish Moss Bleacher position, it’s essential to prepare and present your skills and experience effectively. Here are some tips:

1. Research the Company and Role

Familiarize yourself with the company, its products, and the specific responsibilities of the Irish Moss Bleacher role. This will demonstrate your interest and understanding of the opportunity.

2. Highlight Relevant Experience

Emphasize your experience in bleaching and preparation processes, quality control, production management, and equipment maintenance. Quantify your accomplishments with specific examples and metrics whenever possible.

3. Demonstrate Technical Knowledge

Be prepared to discuss the bleaching process, chemical properties, and quality control procedures. Show your understanding of the industry standards and best practices.

4. Convey Strong Work Ethic and Attention to Detail

Irish Moss Bleaching requires a high level of precision and attention to detail. Highlight your commitment to safety, quality, and accuracy in your responses.

5. Practice and Prepare Answers

Anticipate common interview questions and prepare your answers in advance. Practice delivering your responses clearly and concisely.

6. Dress Professionally and Show Enthusiasm

First impressions matter. Dress appropriately for the interview and show genuine enthusiasm for the opportunity. Your positive attitude and professional demeanor will increase your chances of success.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Irish Moss Bleacher role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.