Are you gearing up for a career in Iron and Steel Work Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Iron and Steel Work Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

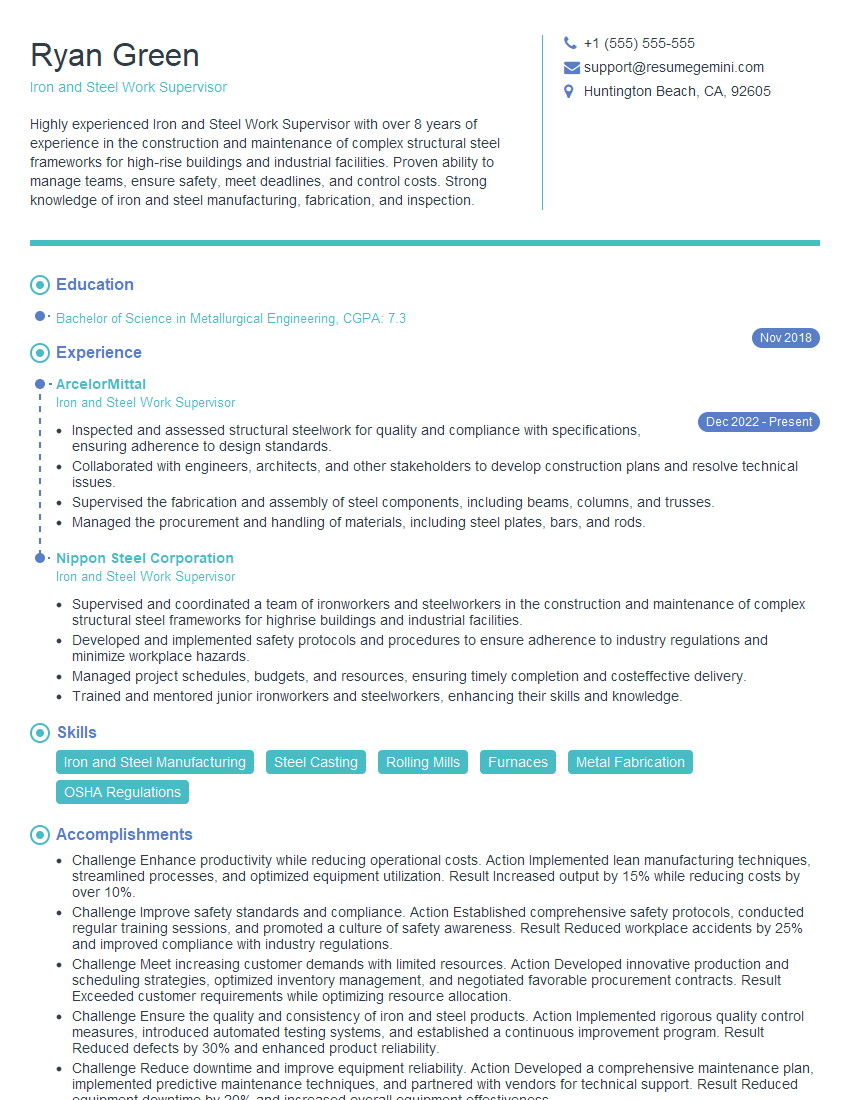

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Iron and Steel Work Supervisor

1. Explain the different types of iron and steel, and their properties?

There are many different types of iron and steel, each with its own unique properties. Some of the most common types of iron include:

- Pig iron: This is the most basic form of iron, and it is produced by smelting iron ore in a blast furnace. Pig iron is very brittle and hard, and it is not suitable for most applications. However, it can be used to produce other forms of iron, such as wrought iron and cast iron.

- Wrought iron: Wrought iron is produced by heating pig iron in a forge and hammering it to remove impurities. Wrought iron is more ductile and malleable than pig iron, and it is suitable for a variety of applications, such as making tools, nails, and chains.

- Cast iron: Cast iron is produced by melting pig iron and pouring it into a mold. Cast iron is very strong and durable, and it is often used to make cookware, machinery, and other products that require strength and durability.

Some of the most common types of steel include:

- Carbon steel: Carbon steel is the most common type of steel, and it is produced by adding carbon to iron. Carbon steel is strong and durable, and it is used in a wide variety of applications, such as making buildings, bridges, and cars.

- Alloy steel: Alloy steel is produced by adding other elements to iron, such as chromium, nickel, and molybdenum. Alloy steel is stronger and more durable than carbon steel, and it is often used in applications where strength and durability are critical, such as in aircraft and spacecraft.

- Stainless steel: Stainless steel is a type of alloy steel that is resistant to corrosion. Stainless steel is used in a wide variety of applications, such as making cookware, cutlery, and medical equipment.

2. What are the different processes involved in iron and steel production?

Iron production

- Mining: Iron ore is mined from the earth.

- Smelting: Iron ore is smelted in a blast furnace to produce pig iron.

- Refining: Pig iron is refined to remove impurities and produce wrought iron or cast iron.

Steel production

- Steelmaking: Steel is produced by adding carbon to iron.

- Rolling: Steel is rolled into various shapes, such as sheets, plates, and bars.

- Finishing: Steel is finished by processes such as heat treatment, coating, and galvanizing.

3. What are the different types of welding processes used in iron and steel fabrication?

- Arc welding: Arc welding is a type of welding that uses an electric arc to melt the metal together. Arc welding is a versatile process that can be used to weld a variety of metals, including iron and steel.

- MIG welding: MIG welding is a type of arc welding that uses a metal inert gas (MIG) to shield the weld from the atmosphere. MIG welding is a fast and efficient process that is well-suited for welding thin metals.

- TIG welding: TIG welding is a type of arc welding that uses a tungsten inert gas (TIG) to shield the weld from the atmosphere. TIG welding is a precise process that is well-suited for welding thick metals.

- Oxy-fuel welding: Oxy-fuel welding is a type of welding that uses a mixture of oxygen and acetylene to create a flame that melts the metal together. Oxy-fuel welding is a versatile process that can be used to weld a variety of metals, including iron and steel.

- Laser welding: Laser welding is a type of welding that uses a laser to melt the metal together. Laser welding is a fast and precise process that is well-suited for welding thin metals.

4. What are the different types of cutting processes used in iron and steel fabrication?

- Oxy-fuel cutting: Oxy-fuel cutting is a type of cutting process that uses a mixture of oxygen and acetylene to create a flame that cuts through the metal. Oxy-fuel cutting is a versatile process that can be used to cut a variety of metals, including iron and steel.

- Plasma cutting: Plasma cutting is a type of cutting process that uses a plasma torch to cut through the metal. Plasma cutting is a fast and precise process that is well-suited for cutting thick metals.

- Laser cutting: Laser cutting is a type of cutting process that uses a laser to cut through the metal. Laser cutting is a fast and precise process that is well-suited for cutting thin metals.

- Waterjet cutting: Waterjet cutting is a type of cutting process that uses a high-pressure water jet to cut through the metal. Waterjet cutting is a precise process that can be used to cut a variety of materials, including iron and steel.

5. What are the different types of testing used to ensure the quality of iron and steel products?

- Tensile testing: Tensile testing is a type of testing that measures the strength of a material by pulling it until it breaks. Tensile testing is used to determine the yield strength, ultimate tensile strength, and elongation of a material.

- Hardness testing: Hardness testing is a type of testing that measures the resistance of a material to deformation. Hardness testing is used to determine the hardness of a material.

- Impact testing: Impact testing is a type of testing that measures the toughness of a material by hitting it with a weight. Impact testing is used to determine the toughness of a material.

- Corrosion testing: Corrosion testing is a type of testing that measures the resistance of a material to corrosion. Corrosion testing is used to determine the corrosion resistance of a material.

6. What are the different types of equipment used in iron and steel fabrication?

- Welding machines

- Cutting machines

- Bending machines

- Rolling machines

- Annealing furnaces

- Testing equipment

7. What are the different safety hazards associated with iron and steel fabrication?

- Fire

- Explosion

- Arc flash

- Welding fumes

- Cuts

- Falls

8. What are the different types of personal protective equipment (PPE) used in iron and steel fabrication?

- Safety glasses

- Welding helmet

- Gloves

- Safety shoes

- Respirator

- Ear plugs

9. What are the different types of training required for iron and steel workers?

- Welding training

- Cutting training

- Bending training

- Rolling training

- Annealing training

- Testing training

- Safety training

10. What are the different career opportunities available for iron and steel workers?

- Welder

- Cutter

- Bender

- Roller

- Annealer

- Tester

- Inspector

- Supervisor

- Manager

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Iron and Steel Work Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Iron and Steel Work Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Iron and Steel Work Supervisors are responsible for overseeing and coordinating the fabrication, installation, and maintenance of iron and steel structures. They must have a strong understanding of iron and steel construction techniques, as well as the ability to read and interpret blueprints and specifications.

1. Planning and Scheduling

Iron and Steel Work Supervisors are responsible for planning and scheduling the work of their crews. This includes developing work schedules, assigning tasks, and ensuring that materials and equipment are available when needed.

- Develop work schedules and assign tasks to crew members.

- Coordinate with other trades to ensure timely completion of projects.

- Monitor progress of work and make adjustments as necessary.

2. Safety Management

Iron and steel work can be hazardous, so supervisors must be committed to safety. They must ensure that their crews are properly trained and equipped, and that all safety regulations are followed.

- Develop and implement safety programs and procedures.

- Train crew members on safety hazards and safe work practices.

- Inspect work areas and equipment regularly to identify and eliminate hazards.

3. Quality Control

Iron and steel work must meet strict quality standards. Supervisors are responsible for ensuring that the work of their crews meets these standards. They must inspect finished work and make sure that it is up to code.

- Inspect finished work to ensure that it meets specifications.

- Identify and correct any defects or errors.

- Maintain quality control records.

4. Communication and Coordination

Iron and Steel Work Supervisors must be able to communicate effectively with their crews, other trades, and clients. They must be able to clearly explain instructions, resolve problems, and keep everyone informed of progress.

- Communicate with crew members, other trades, and clients.

- Resolve problems and conflicts.

- Keep everyone informed of progress and any changes to the schedule.

Interview Tips

In order to ace the interview for an Iron and Steel Work Supervisor position, there are a few things you can do to prepare. Here are some tips:

Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific Anforderungen of the position.

Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked. Practice answering these questions in advance so that you can deliver clear and concise answers on the day of the interview.

Highlight Your Relevant Skills and Experience

In your interview, be sure to highlight your relevant skills and experience. This includes your experience in iron and steel work, your safety knowledge, your quality control experience, and your communication and coordination skills.

Ask Questions

At the end of the interview, be sure to ask the interviewer any questions you have about the position or the company. This shows that you are interested in the opportunity and that you are taking the interview seriously.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Iron and Steel Work Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.