Are you gearing up for a career in Iron Carrier? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Iron Carrier and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

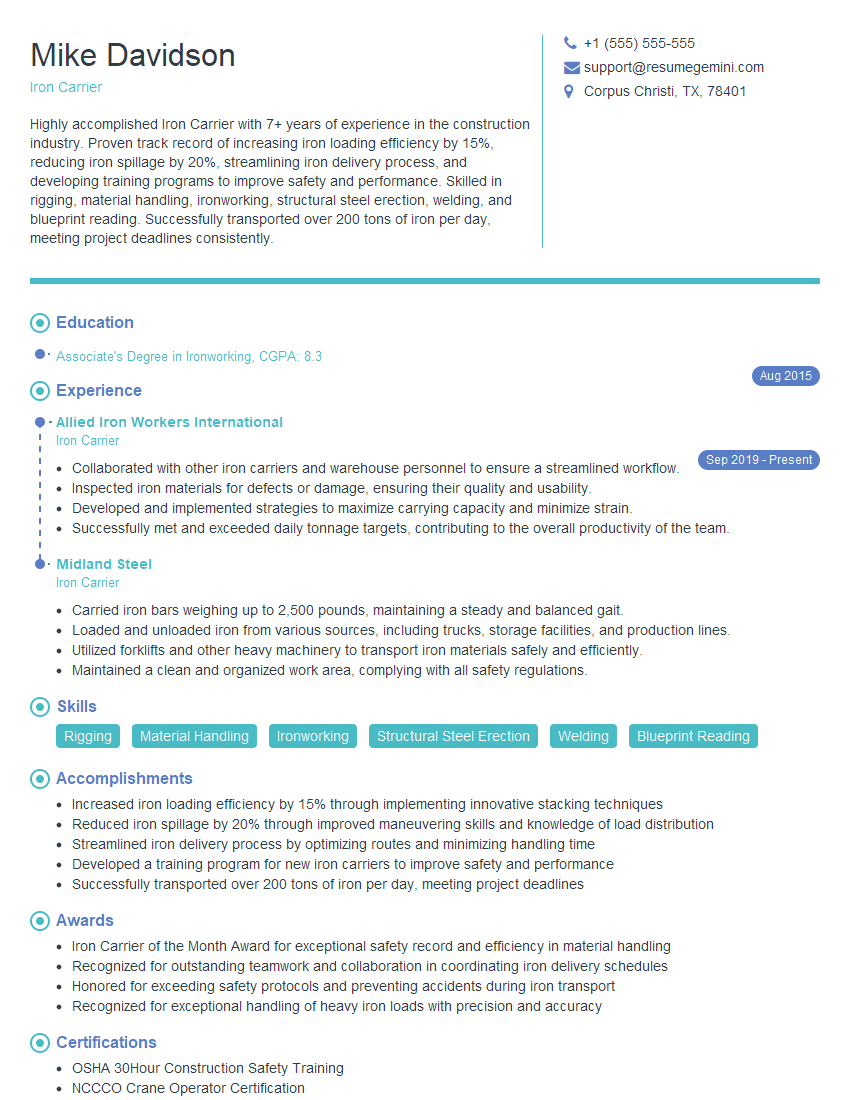

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Iron Carrier

1. What are the key differences between hot rolled and cold rolled iron?

Hot rolled iron is produced by rolling iron at a high temperature, above the recrystallization temperature, while cold rolled iron is produced by rolling iron at a temperature below the recrystallization temperature.

- Hot rolled iron has a rougher surface than cold rolled iron.

- Hot rolled iron is stronger than cold rolled iron.

- Hot rolled iron is more ductile than cold rolled iron.

- Cold rolled iron has a smoother surface than hot rolled iron.

- Cold rolled iron is less strong than hot rolled iron.

- Cold rolled iron is less ductile than hot rolled iron.

2. What are the different types of iron ores?

Hematite

- Most common type of iron ore.

- Reddish-brown color.

- High iron content (60-70%).

Magnetite

- Black color.

- Magnetic.

- High iron content (50-60%).

Limonite

- Yellowish-brown color.

- Hydrated form of iron oxide.

- Low iron content (20-30%).

Siderite

- Grayish-white color.

- Carbonate form of iron ore.

- Low iron content (20-30%).

3. What is the process of iron making?

Iron making is the process of extracting iron from iron ore. The process involves the following steps:

- Mining: Iron ore is mined from the earth.

- Crushing: The iron ore is crushed into small pieces.

- Beneficiation: The crushed iron ore is beneficiated to remove impurities.

- Sintering: The beneficiated iron ore is sintered to form pellets.

- Blast furnace: The pellets are charged into a blast furnace along with coke and limestone.

- Smelting: The coke is burned to produce heat, which melts the iron ore and limestone.

- Tapping: The molten iron is tapped from the blast furnace.

4. What is the difference between pig iron and steel?

- Pig iron is a high-carbon iron that is produced directly from the blast furnace.

- Steel is a low-carbon iron that is produced by refining pig iron.

5. What are the different types of steel?

Carbon steels

- Plain carbon steels

- Alloy steels

Alloy steels

- Low-alloy steels

- High-alloy steels

Stainless steels

- Austenitic stainless steels

- Ferritic stainless steels

- Martensitic stainless steels

- Duplex stainless steels

6. What are the different properties of steel?

Mechanical properties

- Strength

- Hardness

- Ductility

- Toughness

Physical properties

- Density

- Melting point

- Electrical conductivity

- Thermal conductivity

Chemical properties

- Corrosion resistance

- Oxidation resistance

- Wear resistance

7. What are the different applications of steel?

- Construction

- Automotive

- Shipbuilding

- Railroad

- Aerospace

8. What are the latest trends in steel production?

- Increased use of electric arc furnaces

- Development of new steel grades

- Increased use of automation and robotics

- Focus on sustainability

9. What are the challenges facing the steel industry?

- Global economic conditions

- Competition from other materials

- Environmental regulations

- Shortage of skilled workers

10. What is the future of the steel industry?

The future of the steel industry is bright. Steel is a versatile and sustainable material that is essential for modern society. The industry is facing challenges, but it is also adapting and innovating. The future of steel is in high-strength, lightweight, and corrosion-resistant steels. These steels will be used in a variety of applications, including construction, automotive, and aerospace.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Iron Carrier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Iron Carrier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Iron Carriers are responsible for the safe and efficient transportation of iron materials in a variety of industrial settings, such as foundries, steel mills, and construction sites. Their primary duties involve operating and maintaining heavy machinery, ensuring the timely delivery of materials, and adhering to safety protocols.

1. Material Handling and Transportation

Iron Carriers are primarily responsible for the transportation of iron materials, which can come in various forms such as bars, sheets, or castings. They operate equipment like forklifts, cranes, and conveyor belts to move materials from storage areas to production lines or designated locations. Ensuring the safe and timely delivery of these materials is crucial to maintain smooth operations in the workplace.

2. Machinery Operation and Maintenance

Iron Carriers are skilled in operating heavy machinery, including forklifts, cranes, and other equipment used for material handling. They are responsible for the daily maintenance and inspection of these machines to ensure they are in good working condition. Regular checks on fluid levels, tire pressure, and overall functionality are essential to prevent breakdowns and accidents.

- Operate forklifts to transport iron materials.

- Use cranes to lift and move heavy iron objects.

- Maintain and inspect equipment to ensure safe operation.

3. Safety Compliance

Iron Carriers play a vital role in maintaining a safe work environment. They are required to follow established safety protocols, such as wearing appropriate personal protective equipment (PPE), adhering to load limits, and operating machinery according to safety guidelines. They are also responsible for identifying and reporting any potential hazards or unsafe conditions.

- Wear appropriate PPE, such as hard hats, safety glasses, and gloves.

- Follow established safety protocols and load limits.

- Identify and report potential hazards or unsafe conditions.

4. Communication and Coordination

Iron Carriers often work in coordination with other team members, including forklift operators, crane operators, and production personnel. Effective communication and coordination are crucial to ensure smooth material flow, avoid delays, and enhance overall productivity. They must be able to clearly communicate instructions, report any issues, and work efficiently as part of a team.

- Communicate effectively with other team members.

- Coordinate material flow to avoid delays.

- Work efficiently as part of a team.

Interview Tips

Preparing thoroughly for an Iron Carrier interview is essential to showcase your skills and qualifications. Here are some tips to help you ace the interview:

1. Research the Company and Role

Before the interview, take the time to research the company and the specific Iron Carrier role you are applying for. This will give you a good understanding of the company culture, job requirements, and what the interviewer might be looking for in a candidate.

- Visit the company website to learn about their history, mission, and products/services.

- Read online reviews and articles about the company to gather insights into its culture and work environment.

- Carefully review the job description to identify the key responsibilities and qualifications required for the role.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your skills and experience. Practice answering questions related to your material handling abilities, machinery operation, safety knowledge, and teamwork experience. You can also prepare questions to ask the interviewer, demonstrating your interest in the role and the company.

- Tell me about your experience operating heavy machinery.

- How do you ensure safety while working with heavy loads?

- Describe a situation where you had to work effectively as part of a team to transport materials.

3. Highlight Your Relevant Skills and Experience

During the interview, emphasize your relevant skills and experience that align with the job requirements. Showcase your proficiency in operating heavy machinery, your understanding of safety protocols, and your ability to work efficiently in a team environment. Provide specific examples to demonstrate your capabilities and how you can contribute to the company.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing context and highlighting your role in achieving positive outcomes.

- Be enthusiastic and confident in presenting your skills and experience, but also be humble and willing to learn.

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally for the interview and arrive on time. Punctuality demonstrates respect for the interviewer’s time and shows that you are organized and reliable.

- Choose attire that is clean, pressed, and appropriate for an industrial work environment.

- Arrive at the interview location a few minutes early to allow time for any unexpected delays.

5. Ask Thoughtful Questions

At the end of the interview, be prepared to ask thoughtful questions that show your interest in the role and the company. This is an opportunity to clarify any uncertainties, demonstrate your enthusiasm, and leave a lasting impression.

- Ask about the company’s safety record and their commitment to employee training and development.

- Inquire about the company’s plans for future growth and how the Iron Carrier role fits into those plans.

- Thank the interviewer for their time and consideration.

Next Step:

Now that you’re armed with the knowledge of Iron Carrier interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Iron Carrier positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini