Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Iron Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

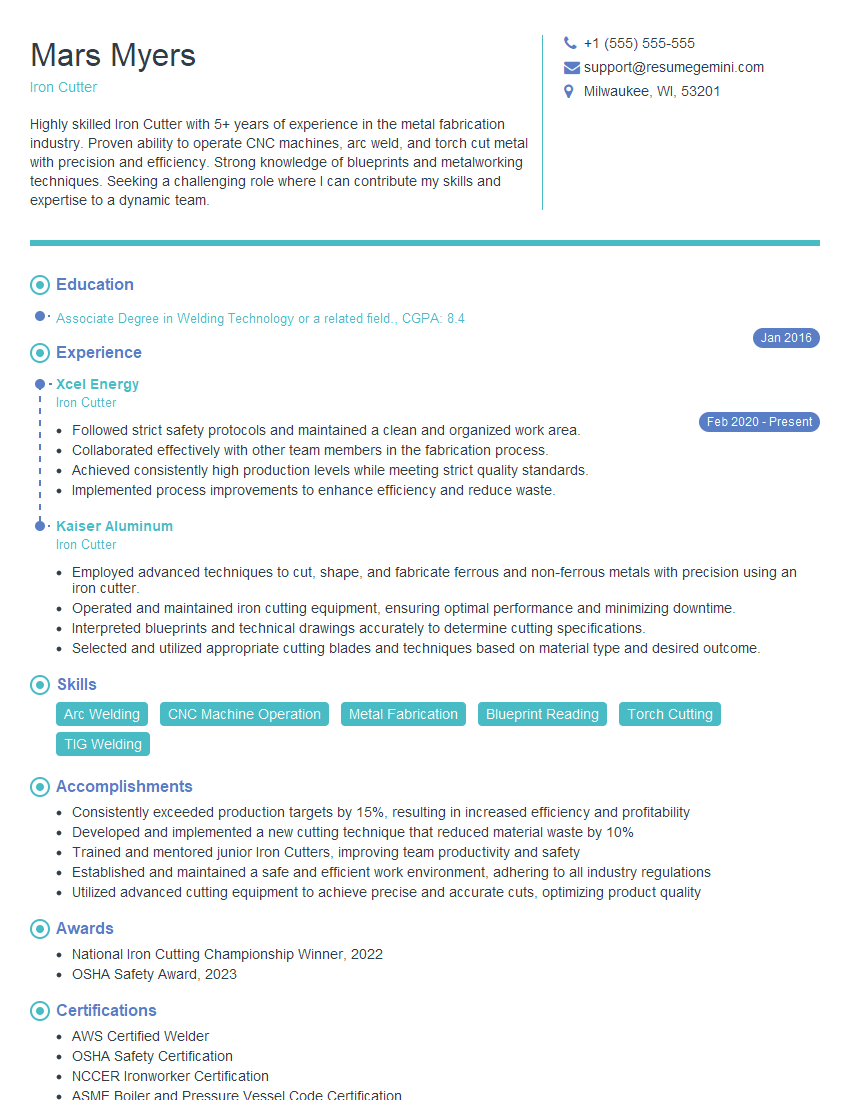

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Iron Cutter

1. What are the different types of iron cutters and their uses?

Iron cutters are used to cut various types of ferrous metals. There are three main types of iron cutters:

- Hydraulic Iron Cutters: These cutters use hydraulic pressure to cut metal bars and rods. They are powerful and can cut through thick metals easily.

- Lever Iron Cutters: These cutters use a lever mechanism to cut metal. They are manually operated and require more effort to cut through thick metals.

- Guillotine Iron Cutters: These cutters use a guillotine blade to cut metal. They are powerful and can cut through thick metals quickly.

2. What are the safety precautions that should be taken when using an iron cutter?

- Wear appropriate safety gear, including eye protection, gloves, and hearing protection.

- Secure the metal before cutting to prevent it from moving.

- Keep hands clear of the cutting area.

- Do not overload the cutter.

- Inspect the cutter before each use and ensure it is in good working condition.

3. How do you determine the correct blade for an iron cutter?

The correct blade for an iron cutter depends on the thickness and type of metal being cut. Thicker metals require a blade with a larger diameter and more teeth. Harder metals require a blade with a higher Rockwell hardness rating.

4. What is the difference between a cold cut and a hot cut?

- Cold Cut: A cold cut is made with a blade that is not heated. This type of cut is used for cutting thin metals and metals that are not prone to hardening.

- Hot Cut: A hot cut is made with a blade that is heated. This type of cut is used for cutting thick metals and metals that are prone to hardening.

5. What are the common problems that can occur when using an iron cutter?

- Dull Blades: Dull blades can cause the cutter to struggle to cut through the metal and can lead to premature blade failure.

- Misalignment: Misalignment between the blade and the anvil can cause the cutter to cut unevenly or not at all.

- Overloading: Overloading the cutter can cause the blade to break or the motor to burn out.

- Insufficient Lubrication: Insufficient lubrication can cause the cutter to overheat and fail.

6. How do you troubleshoot an iron cutter that is not cutting properly?

- Check the blade for dullness or damage.

- Check the alignment of the blade and the anvil.

- Check the motor for overheating or burning.

- Check the lubrication system for leaks or blockages.

7. What is the proper maintenance schedule for an iron cutter?

- Clean the cutter after each use.

- Lubricate the cutter regularly.

- Inspect the blade for dullness or damage before each use.

- Have the cutter serviced by a qualified technician annually.

8. What are the advantages of using an iron cutter over other cutting tools?

- Precision: Iron cutters provide precise cuts with minimal burrs.

- Speed: Iron cutters can cut through metal quickly and efficiently.

- Versatility: Iron cutters can be used to cut a variety of ferrous metals.

- Durability: Iron cutters are durable tools that can withstand heavy use.

9. What are the different applications for iron cutters?

- Cutting metal bars and rods

- Cutting metal sheets

- Cutting metal pipes

- Cutting metal beams

10. How do you calculate the cutting capacity of an iron cutter?

The cutting capacity of an iron cutter is determined by the diameter of the blade and the thickness of the metal being cut. The following formula can be used to calculate the cutting capacity:

Cutting Capacity = (Blade Diameter / 2) – (Metal Thickness)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Iron Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Iron Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Iron Cutters use a variety of tools and equipment to cut, shape, and fabricate metal objects. They must be able to read blueprints and follow instructions precisely. Their primary responsibilities include:

1. Cutting and Shaping Metal

Iron Cutters use a variety of tools to cut and shape metal, including:

- Saws

- Shears

- Punches

- Presses

2. Fabricating Metal Objects

Iron Cutters also use their skills to fabricate metal objects, such as:

- Frames

- Brackets

- Tanks

- Pipes

3. Reading Blueprints and Following Instructions

Iron Cutters must be able to read blueprints and follow instructions precisely in order to ensure that their work meets specifications.

4. Maintaining a Safe Work Environment

Iron Cutters must follow all safety protocols and maintain a clean and organized work environment.

Interview Tips

Interviews for Iron Cutter positions generally focus on an individual’s technical knowledge and experience. To prepare, consider the following tips:

1. Brush up on your technical knowledge

This includes knowledge of different types of metals, metalworking tools, and fabrication techniques.

2. Be prepared to discuss your experience

Highlight your experience in cutting and shaping metal, as well as your ability to read blueprints and follow instructions.

3. Showcase your safety awareness

Emphasize your commitment to following safety protocols and maintaining a clean and organized work environment.

4. Be enthusiastic and positive

This is a physically demanding job, so employers will be looking for candidates who are enthusiastic and have a positive attitude.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Iron Cutter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.